Method for preparing explosive composite rod based on water pressure in local vacuum environment

A partial vacuum and composite rod technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as ablation damage on the surface of composite rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Provided in conjunction with the accompanying drawings, a method for preparing explosive composite rods based on hydraulic pressure in a partial vacuum environment includes the following steps:

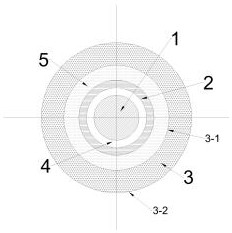

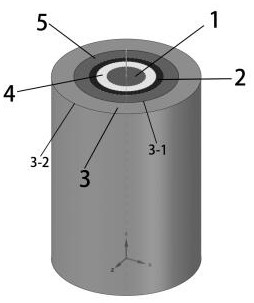

[0018] 1) Coaxially arrange the to-be-composited rod 1, the to-be-composited pipe 2, the small-sized PVC pipe 3-1, and the large-sized PVC pipe 3-2 from the inside to the outside;

[0019] 2) Seal and vacuum both ends of the gap between the rod to be compounded 1 and the pipe to be compounded 2 with a sealing strip to construct a vacuum gap environment 4;

[0020] 3) filling explosives and detonators between the pvc pipe 3-1 and pvc pipe 3-2 to form an explosive device 3;

[0021] 4) Fill water between the pipe to be composited 2 and the explosive device to construct a water environment 5;

[0022] 5) The detonation explosion d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com