Preparation method of explosion composite pipe rod in vacuum environment

A vacuum environment, composite tube technology, applied in the direction of manufacturing tools, welding equipment, tubular objects, etc., can solve the problems of affecting the bonding quality of the composite materials, loss of universality, and low energy utilization rate of explosives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

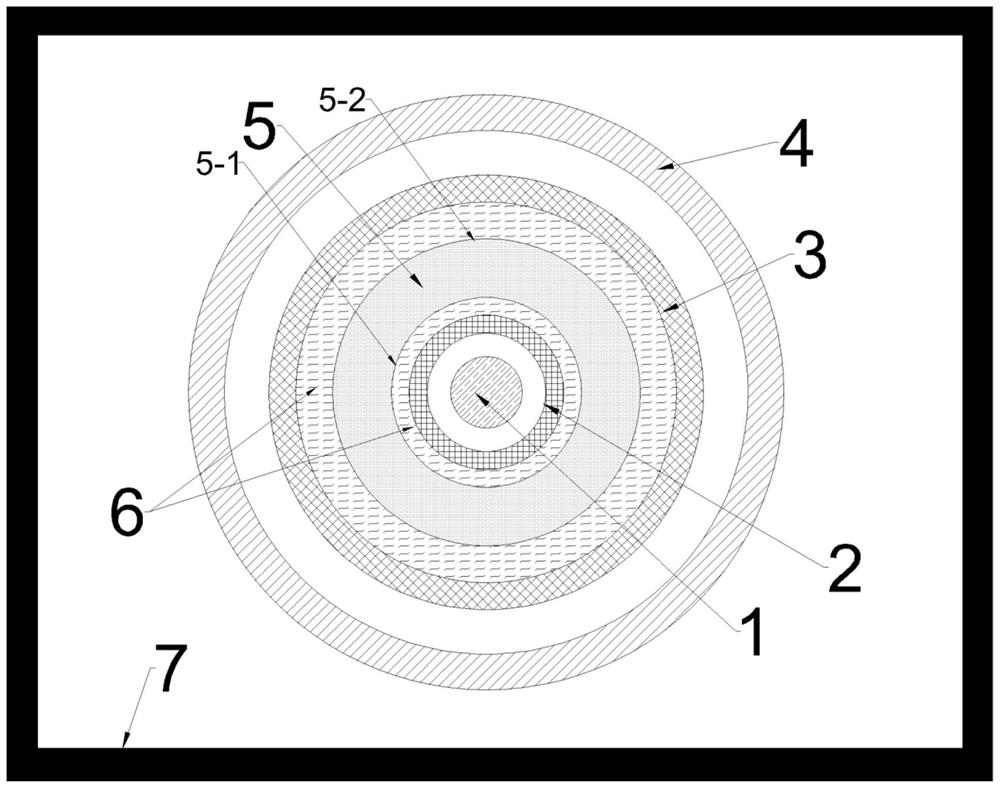

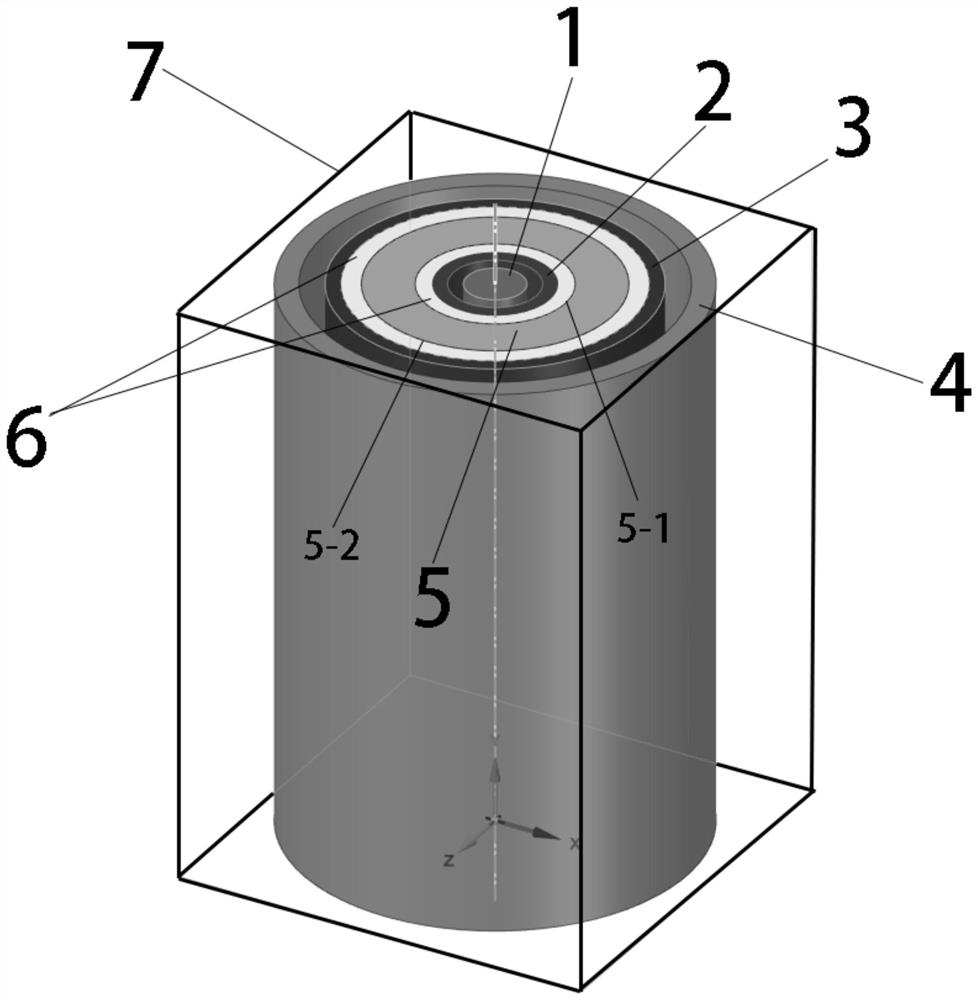

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Provided in conjunction with the accompanying drawings, a method for preparing an explosive composite pipe rod in a vacuum environment includes the following steps:

[0017] 1) The metal rod 1, the metal pipe 2, the pvc pipe 5-1, the pvc pipe 5-2, the metal pipe 3, and the metal pipe 4 are arranged coaxially from the inside to the outside;

[0018] 2) filling explosive compound explosives and detonators between the pvc pipe 5-1 and pvc pipe 5-2 to form the explosive device 5;

[0019] 3) Fill the space between the pipe to be composited and the explosive device with water to construct a water environment 6;

[0020] 4) Put the composite material, the explosive device and the water environment into the vacuum tank 7 as a whole and evacuate to build a vacuum environment;

[0021] 5) The explosive device is detonated to mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com