Re-drilling concrete wall protecting method for hole formation of rock-socketed pile in karst region

A technology of rock-socketed piles and concrete retaining walls, which is applied to sheet pile walls, buildings, and infrastructure projects, can solve problems that endanger construction personnel, mechanical equipment safety, and prevent hole wall collapse, water leakage, and slurry leakage in time, and achieve maintenance Stable, wide application range, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

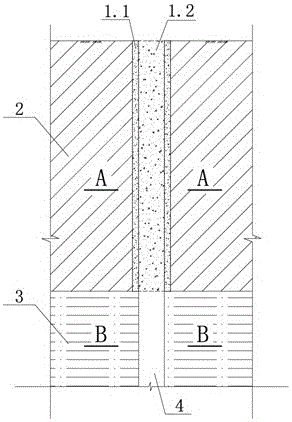

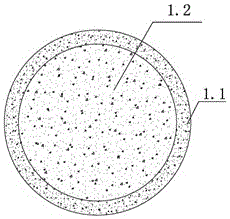

[0016] See Figure 1-3 , The present invention includes the following steps. Firstly, in the overlying soil layer 2, a plain concrete bored pile composed of a protective wall concrete thin-walled tubular pile 1.1 and a core concrete solid pile 1.2 located in the protective wall concrete thin-walled tubular pile 1.1 is constructed. The diameter of the bored concrete pile is larger than the diameter of the hole 4 of the rock-socketed pile, and the length of the pile is the depth from the natural ground to the top surface of the underlying bedrock 3. When the age of the pile body reaches 3~7d, then use the rotary drilling rig The concrete bored pile is cored, the core concrete solid pile is taken out, and the re-drilled concrete wall protection structure is formed by the wall-protecting concrete thin-walled tube pile, and then the underlying bedrock is exposed and the rock-socketed pile is formed in the bedrock stratum.

[0017] The diameter of the cored concrete solid pile is equal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com