Large-diameter super-thick pebble bed hole forming method

A pebble layer, large-diameter technology, applied in the field of large-diameter ultra-thick pebble layer hole formation, can solve the problem of slowness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

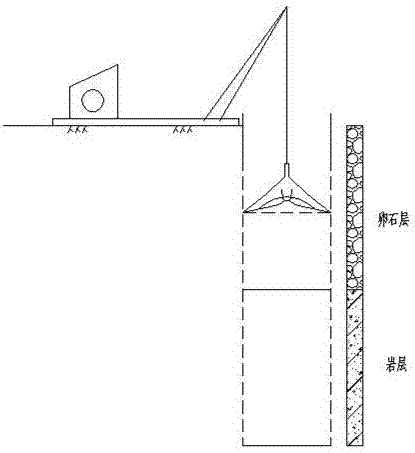

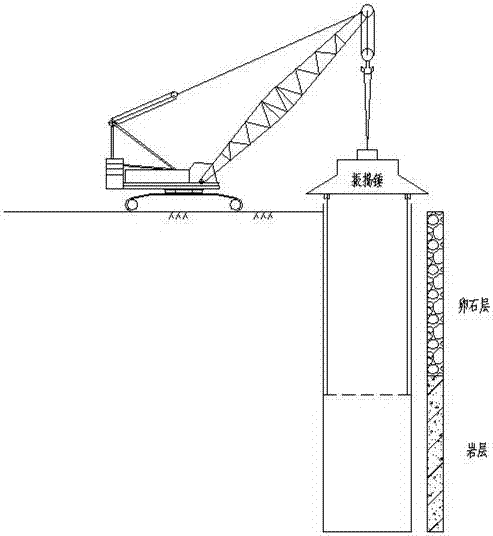

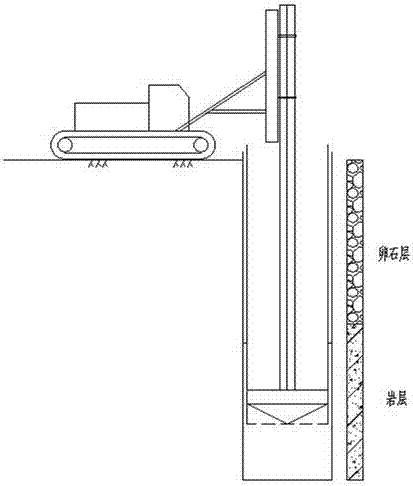

[0017] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 6 Shown: a method for forming holes in a large-diameter ultra-thick pebble layer, carried out in accordance with the following steps:

[0018] First of all, the preparations before construction are carried out. After the site is leveled, the measurement and stakeout are carried out to determine the hole position, and the outer casing is buried, and the percussion drill is accurately positioned;

[0019] Then use the percussion drill in the outer casing to carry out construction. During the drilling process, maintain the guiding effect of the weight to ensure the verticality of the hole. During the process, control the specific gravity of the mud. If the mud is lost or lost, it should be supplemented. And according to the mud inspection regulations, the mud index should be checked on time. In case of changes in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com