Deep-layer one-time hole forming construction method through matching of blasting and rotary drilling rig

A technology of rotary drilling rigs and construction methods, which is applied in the direction of drilling equipment and methods, rotary drilling rigs, blasting, etc., and can solve the problems of high loss of drilling rigs and failure to meet construction progress requirements, and achieve high hole forming efficiency and lithology differences Larger, the effect of improving the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] A background:

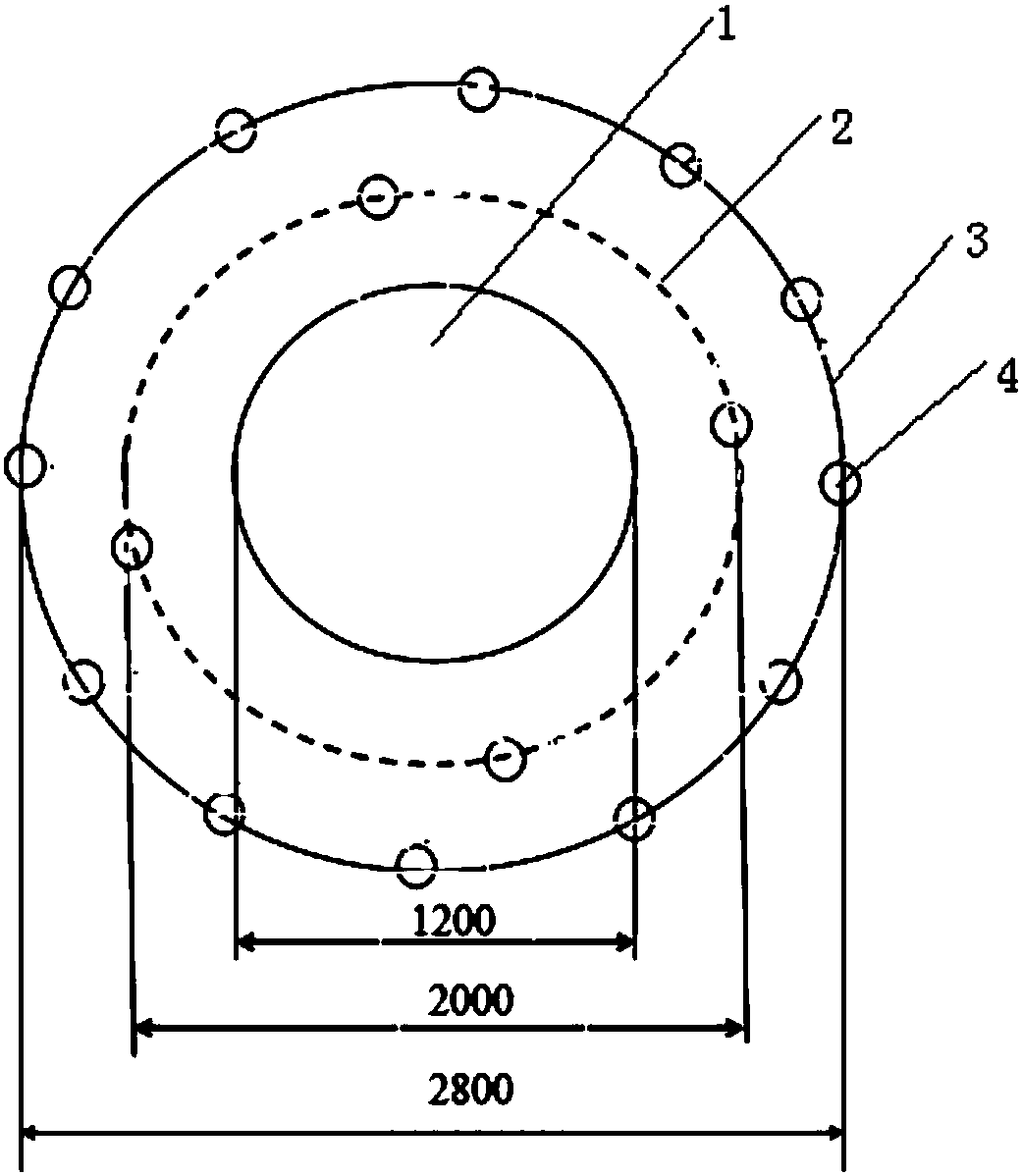

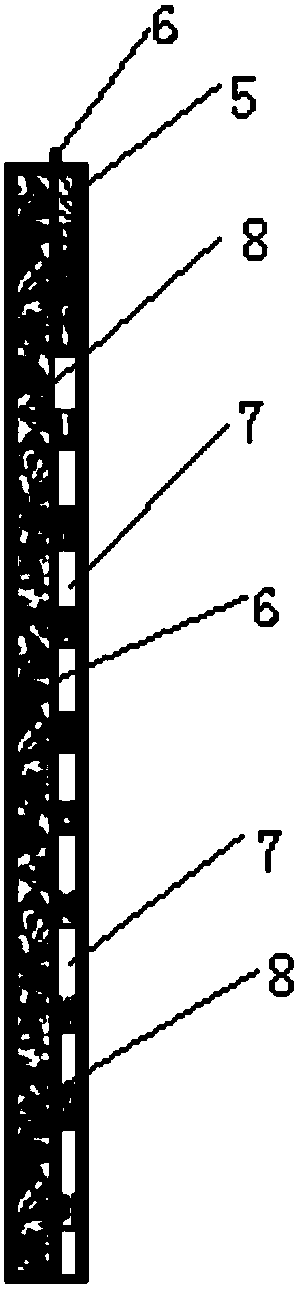

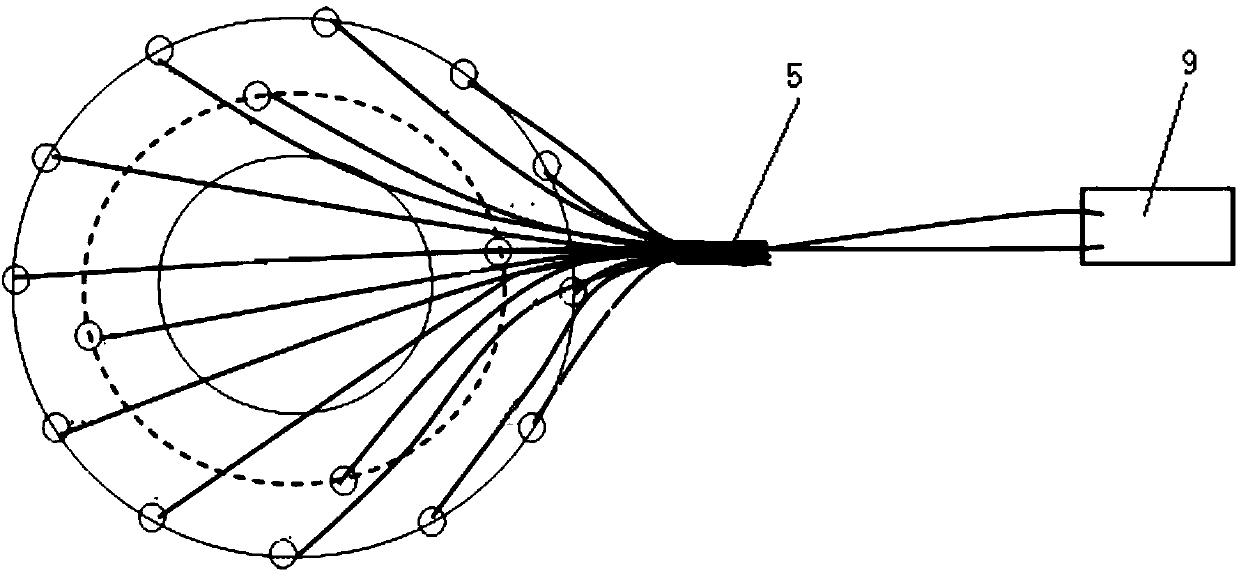

[0042] The blasting site is located at the bank of the Jinsha River on the east side of the hillside of Jin'an Township, Jin'an Township, Gucheng District, Lijiang City. Due to the construction of the national highway network G4216 Chengdu-Lijiang Expressway, cable towers need to be built at both ends of the Jin'an Jinsha River Bridge. The size is 28.8m*28.8m. There are 16 end-bearing piles with a diameter of 2.8m and a pile length of 65m under the cap, and 16 end-bearing piles with a diameter of 2.8m and a pile length of 45m. Due to the steep terrain and large height difference, the upper part of the friction pile is about 11m of tuff, and the lower part has to pass through 55m of moderately weathered and slightly weathered basalt. Except for some interlayers with slightly lower f coefficients, the rest of the f coefficients are between 15 and 35. During the period, the maximum compressive strength of the actual rock formation is as high as 330Mpa, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com