Biting pile construction method and biting pipe applied to method

A construction method and technology of occlusal piles are applied in excavation, sheet pile wall, foundation structure engineering and other directions to achieve the effect of speeding up the progress, improving the hole forming efficiency and reducing the project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, construction method of the present invention is described in detail.

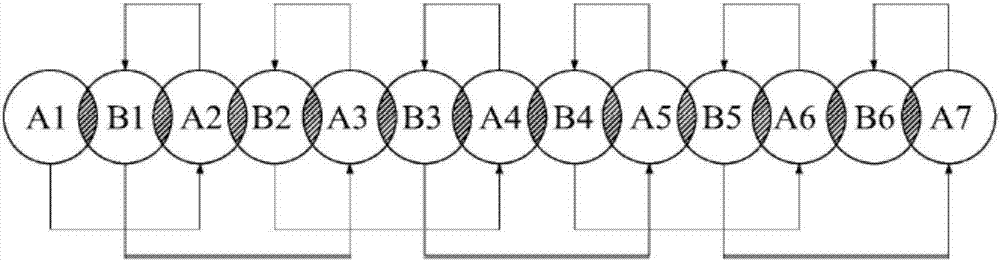

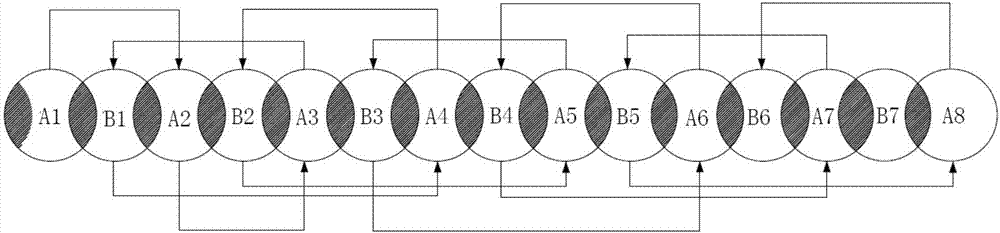

[0028] Such as figure 2 As shown, the construction process of the present invention can be briefly summarized as follows: A1 pile forming hole → burying A1 pile occlusal pipe → pouring A1 pile concrete → A2 pile forming hole → burying A2 pile occlusal pipe → pouring A2 pile concrete → pulling out A1 pile occlusal Pipe→A3 pile forming hole→burying A3 occlusal pipe→pouring A3 pile concrete→pull A2 pile occlusal pipe→B1 pile forming hole→installing B1 pile reinforcement cage→pouring B1 pile concrete→A4 pile forming hole→burying A4 occlusal pipe→pouring Concrete for pile A4 → pull out the occlusal pipe of pile A3 → form a hole for pile B2 → install the reinforcement cage for pile B2 → pour concrete for pile B2... and proceed in this cycle.

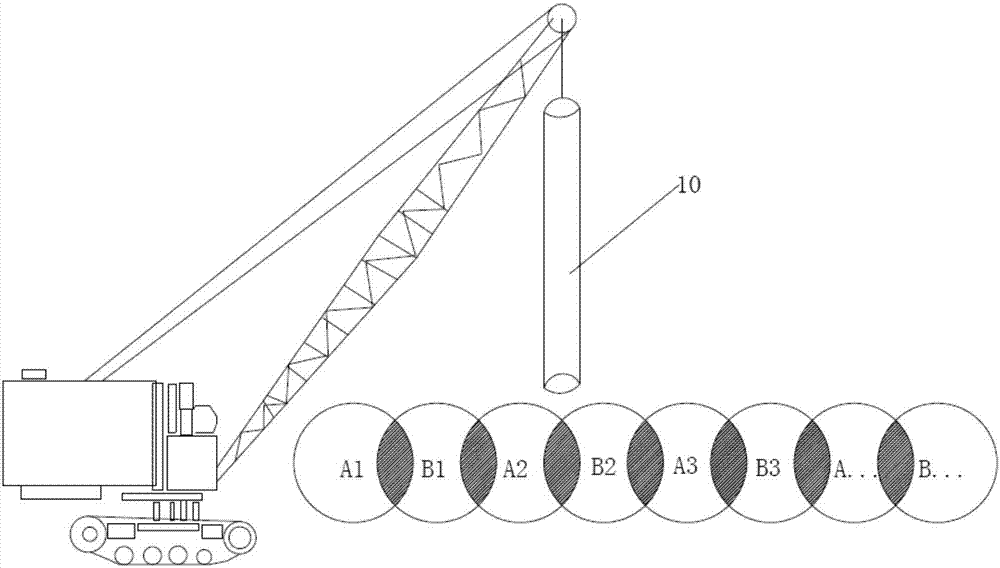

[0029] Refer to the specific construction process figure 2 flow chart and image 3 The schematic diagram of hois...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com