Grinding wheel and grinding apparatus

A grinding and grinding wheel technology, which is applied to grinding drive devices, grinding workpiece supports, grinding machine parts, etc., can solve the problems of insufficient occlusal performance, unable to fully ensure the occlusal performance of the ground surface, etc., and achieve improvement. The effect of occlusal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

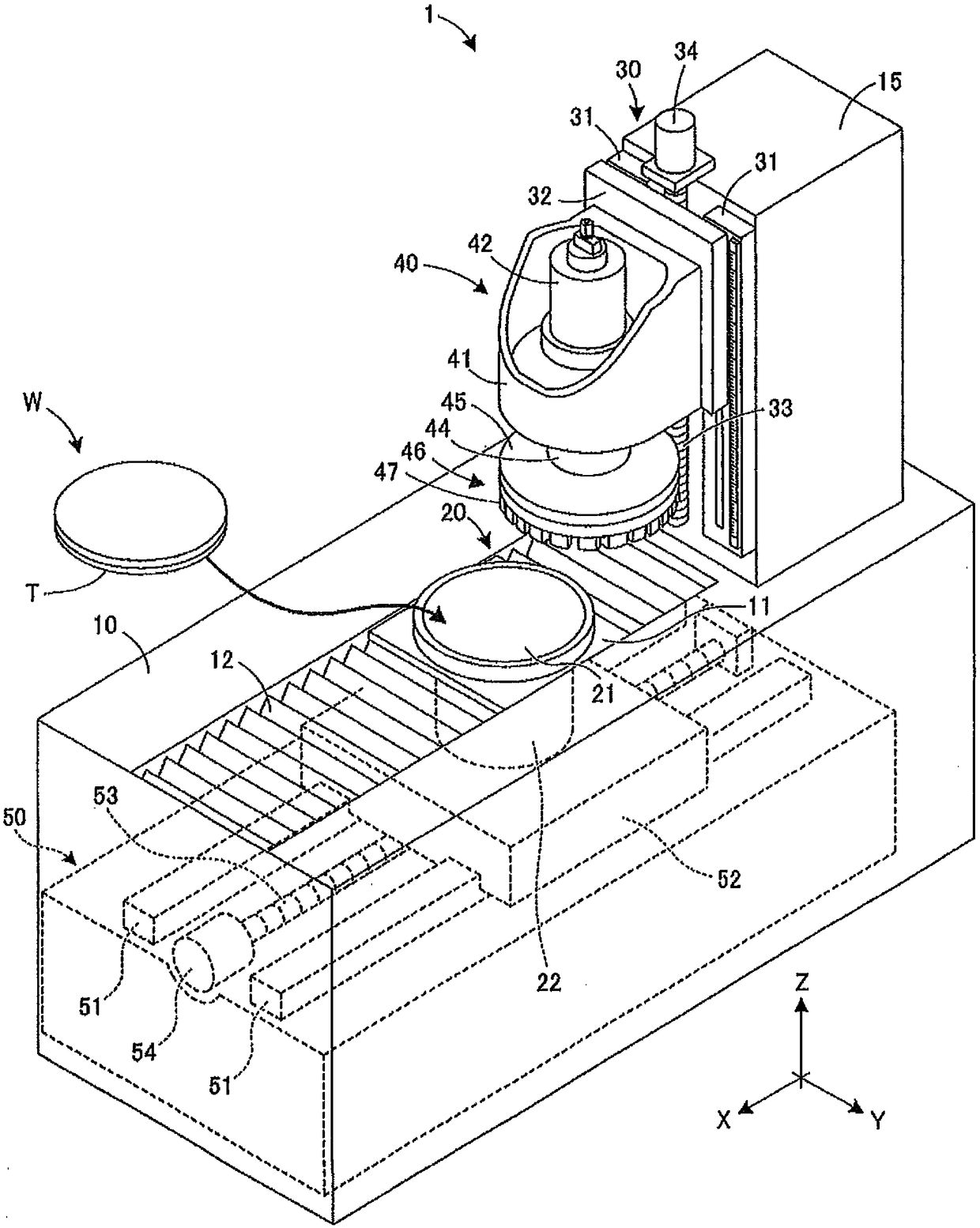

[0019] Hereinafter, a grinding device according to the present embodiment will be described with reference to the drawings. figure 1 It is a perspective view of the grinding apparatus of this embodiment. Additionally, the grinding device is not limited to figure 1 The apparatus structure dedicated to grinding processing as shown can be incorporated into a fully automatic processing apparatus that performs a series of processing such as grinding processing, polishing processing, and cleaning processing in a fully automatic manner, for example.

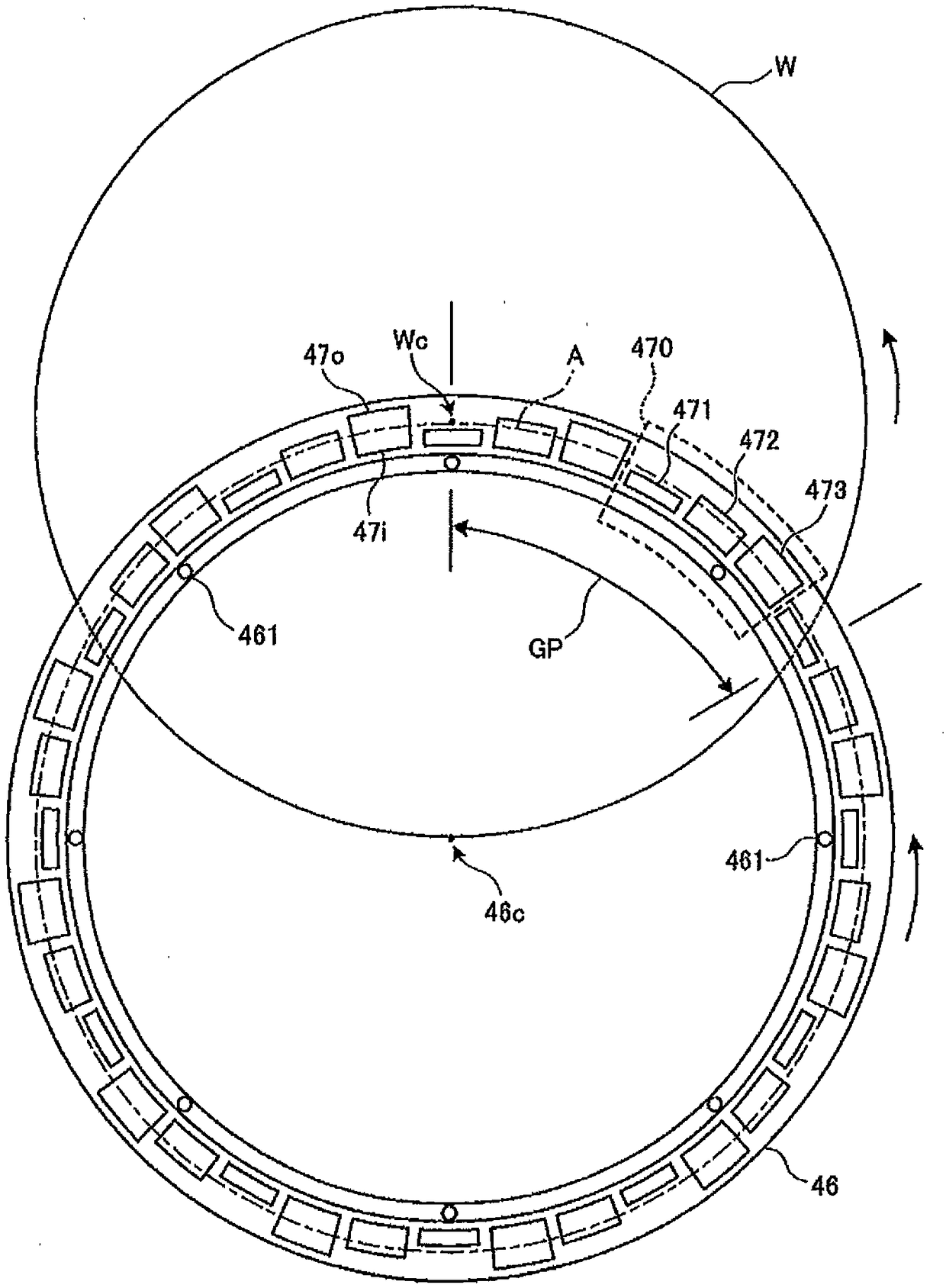

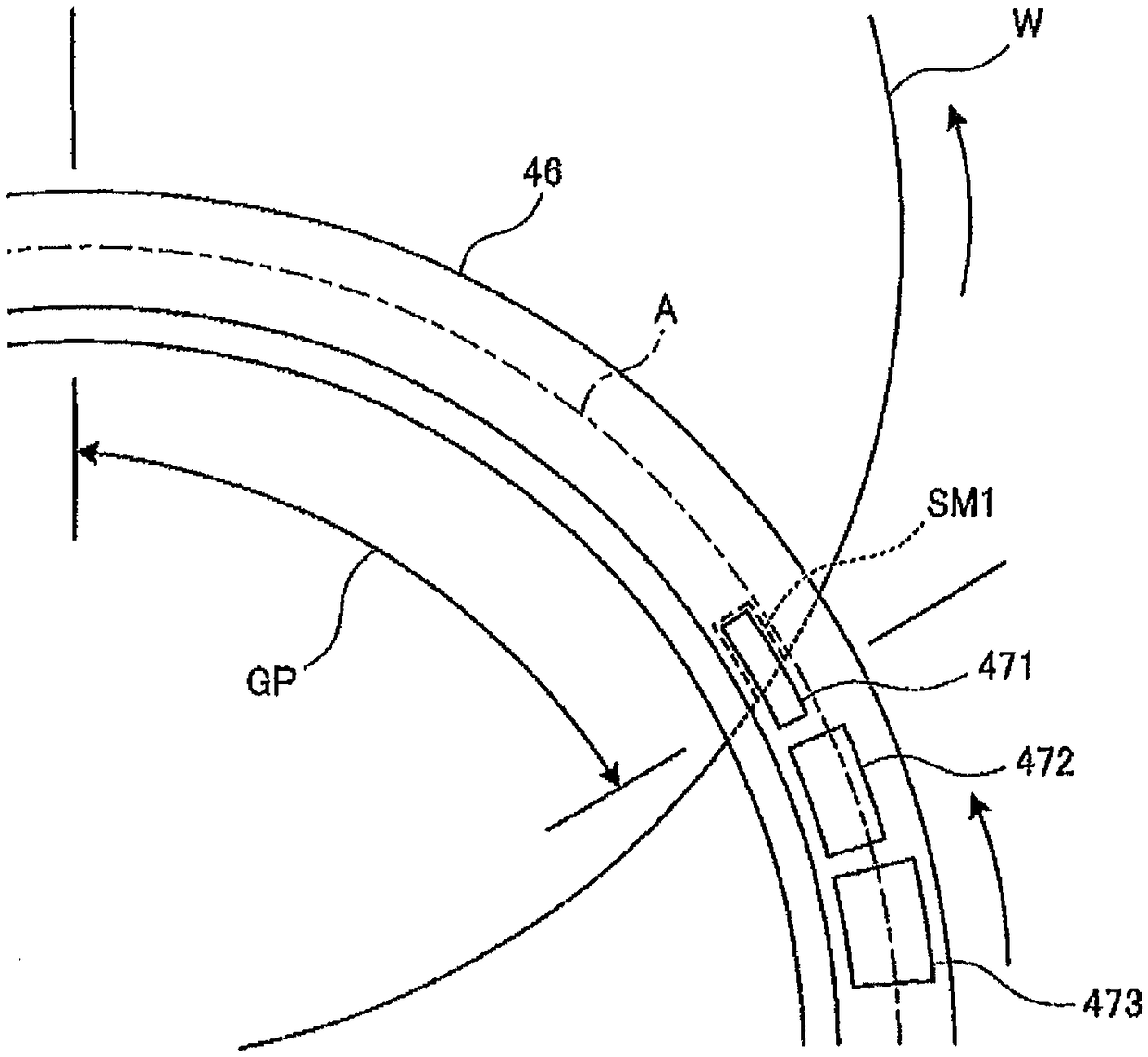

[0020] Such as figure 1 As shown, the grinding apparatus 1 is configured to grind a wafer W held by a chuck table (holding table) 20 using a grinding wheel 46 in which a plurality of segmented grindstones 47 are arranged in an annular shape. The wafer W is loaded into the grinding apparatus 1 with the protective tape T attached thereto, and is held on the holding surface 21 of the chuck table 20 . In addition, as long as the wafer W ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com