Combined paper cutter tool

A paper cutting and cutting tool technology, applied in metal processing, etc., can solve the problems of low processing efficiency, inconvenient assembly and disassembly, low consistency of parts size, etc., and achieve the effect of simple structure and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

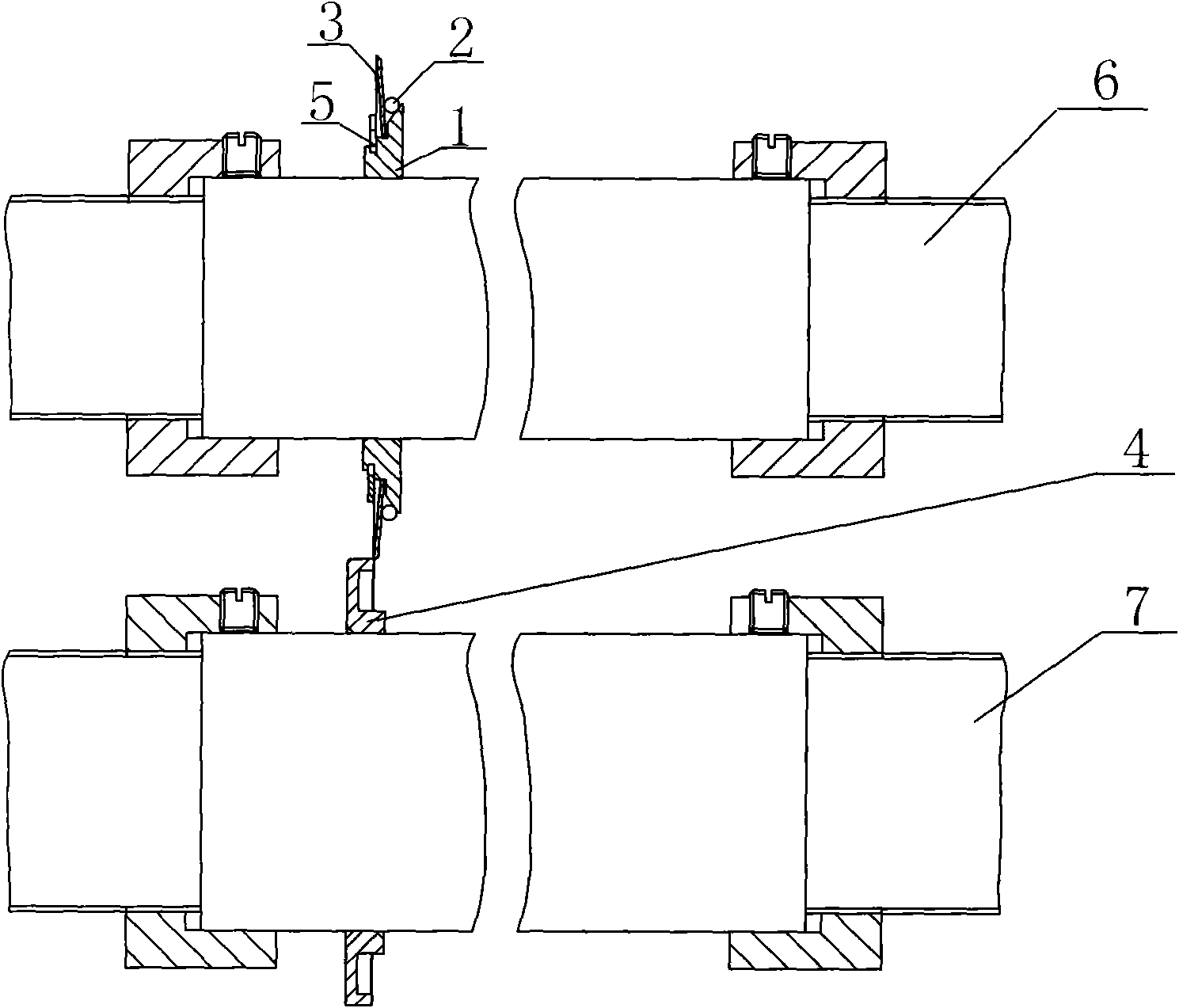

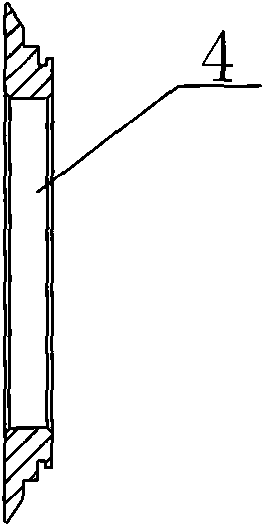

[0022] like figure 1 , a combined paper cutting and thinning machine tool according to the present invention, comprising an upper blade 3 and a lower blade 4 mounted on an upper cutter shaft 6 and a lower cutter shaft 7 respectively, the upper blade 3 is arranged on a knife holder 1, and the A spring 2 is arranged between the above blade 3 and the knife rest 1, and a retaining ring 5 is also arranged on the upper blade 3, and the knife rest 1, the spring 2 and the upper blade 3 are limited and fixedly connected by the retaining ring 5 .

[0023] In this embodiment, the knife rest 1, the spring 2, the upper blade 3 and the retaining ring 5 are fixedly connected through the fit gap, and the tight engagement with the lower blade 4 is realized by adjusting the tightness of the spring 2 to achieve the cutting effect; at the same time Both ends of the upper cutter shaft 6 and the lower cutter shaft 7 are provided with adjusting nuts for adjusting the axial distance of the cutter. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com