Red sandstone fully-weathered substance-based high-compactness filler and preparation method thereof

A fully weathered, red sandstone technology, applied in sustainable biological treatment, roads, buildings, etc., can solve problems such as lack of high-quality fillers, achieve the effect of protecting the environment, improving construction efficiency, and saving project costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following specific embodiments are used to illustrate the embodiments of the present invention. Those who are familiar with the technology can easily understand other advantages and effects of the present invention from the contents disclosed in this specification. Obviously, the described embodiments are part of the present invention. , not all examples. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

[0015] A preparation method of red sandstone full weathered base high compaction filler, comprising the following steps:

[0016] S1. Crushing the weathered red sandstone excavated on site so that its maximum particle size meets the regulations on the particle size of fillers for roadbeds, and obtains broken particles of full weathered red sandstone;

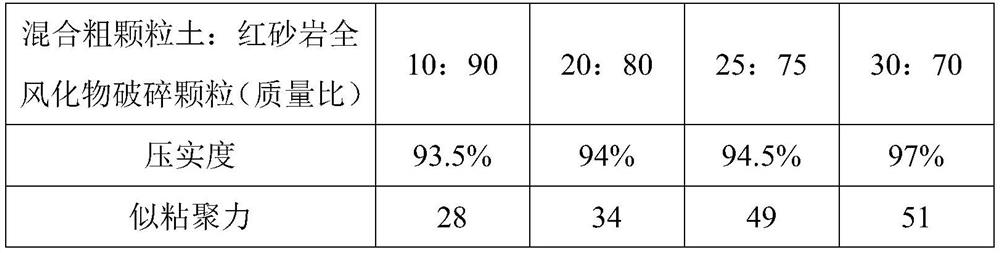

[0017] S2, adopt the method of centralized mixing, acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com