Expansion joint sealing material for waterproof layer of ballastless railway track subgrade surface

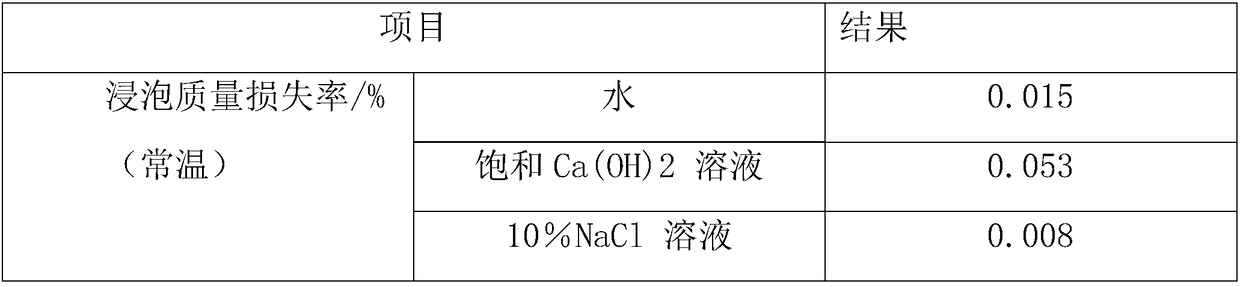

A sealing material, ballastless track technology, applied in the directions of non-polymer adhesive additives, adhesive additives, non-polymer organic compound adhesives, etc. It can solve the problems of low melting and durability and weak interface adhesion, so as to achieve good water immersion stability, maintain stable performance and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The waterproof layer expansion joint sealing material of the railway ballastless track subgrade surface of the present embodiment, the sealing material raw material comprises the following components by weight: 30 parts of epoxy resin, 10 parts of ethylene glycol butyl ether, 5 parts of n-butanol, 5 parts of methacrylic acid, 15 parts of toluene diisocyanate, 5 parts of polyether diol, 5 parts of polyether triol, 1 part of polyphenyl polyisocyanate, 5 parts of polydimethylsilane, 3,3'-di 4 parts of chloro-4,4'-diaminodiphenylmethane, 1 part of dibutyltin dilaurate, 1 part of tin maleate, 20 parts of modified filler, 1 part of tackifier;

[0012] The tackifier is a mixture of γ-glycidyl ether oxypropyl trimethoxysilane and N-β-(aminoethyl)-γ aminopropyl trimethoxysilane, by weight γ-glycidyl ether oxypropyl Trimethoxysilane: N-β-(aminoethyl)-γaminopropyltrimethoxysilane=2:1;

[0013] The modified filler is prepared in the following way: first prepare a mixed solvent of ...

Embodiment 2

[0015] The waterproof layer expansion joint sealing material of the railway ballastless track subgrade surface of the present embodiment, the sealing material raw material comprises the following components by weight: 40 parts of epoxy resin, 20 parts of ethylene glycol butyl ether, 12 parts of n-butanol, 10 parts of methacrylic acid, 25 parts of toluene diisocyanate, 10 parts of polyether diol, 10 parts of polyether triol, 5 parts of polyphenyl polyisocyanate, 10 parts of polydimethylsilane, 3,3'-bis 8 parts of chloro-4,4'-diaminodiphenylmethane, 3 parts of dibutyltin dilaurate, 3 parts of tin maleate, 30 parts of modified filler, 3 parts of tackifier;

[0016] The tackifier is a mixture of γ-glycidyl ether oxypropyl trimethoxysilane and N-β-(aminoethyl)-γ aminopropyl trimethoxysilane, by weight γ-glycidyl ether oxypropyl Trimethoxysilane: N-β-(aminoethyl)-γaminopropyltrimethoxysilane=2:1;

[0017] The modified filler is prepared in the following way: first prepare a mixed s...

Embodiment 3

[0019] The waterproof layer expansion joint sealing material of the railway ballastless track subgrade surface of the present embodiment, the sealing material raw material comprises the following components by weight: 30 parts of epoxy resin, 20 parts of ethylene glycol butyl ether, 5 parts of n-butanol, 10 parts of methacrylic acid, 15 parts of toluene diisocyanate, 10 parts of polyether diol, 5 parts of polyether triol, 5 parts of polyphenyl polyisocyanate, 5 parts of polydimethylsilane, 3,3'-di 8 parts of chloro-4,4'-diaminodiphenylmethane, 1 part of dibutyltin dilaurate, 3 parts of tin maleate, 20 parts of modified filler, 3 parts of tackifier;

[0020] The tackifier is a mixture of γ-glycidyl ether oxypropyl trimethoxysilane and N-β-(aminoethyl)-γ aminopropyl trimethoxysilane, by weight γ-glycidyl ether oxypropyl Trimethoxysilane: N-β-(aminoethyl)-γaminopropyltrimethoxysilane=2:1;

[0021] The modified filler is prepared in the following way: first prepare a mixed solven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com