Warm-mixing recycled asphalt mixture preparation method

A technology of recycled asphalt and mixture, applied in the direction of climate change adaptation, etc., can solve the problems of late start of regeneration and warm mix technology, accelerated secondary aging of recycled asphalt, poor performance of warm mix regeneration, etc., to solve poor road performance, Enhanced low-temperature deformation ability and reduced harmful gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

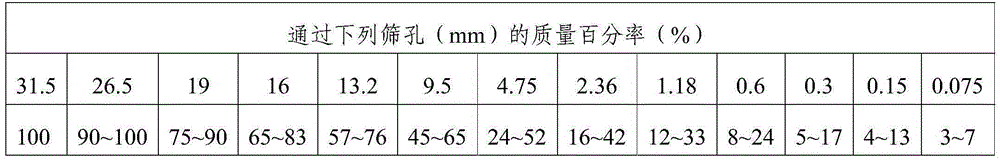

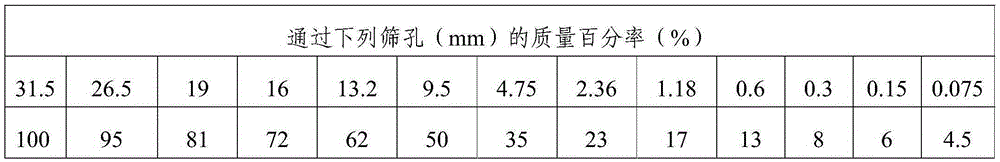

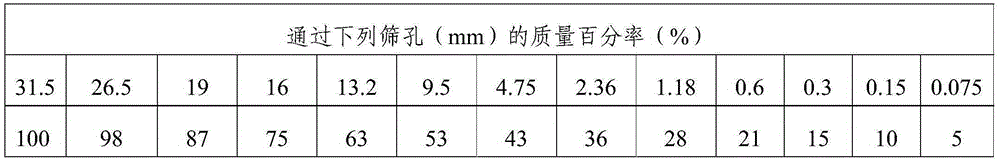

[0031] The gradation type of the warm-mix recycled asphalt mixture prepared in this example is AC-25, and the target gradation is shown in Table 1. The specific preparation method includes the following steps:

[0032] Step 1. After mixing the regenerant, viscosity reducer, plasticizer and anti-aging agent, melt and shear for 7 minutes at a temperature of 180° C. to obtain a composite regenerant; the mass content of the regenerant in the composite regenerant is 65%, the mass content of the viscosity reducer is 32%, the mass content of the plasticizer is 1.2%, and the mass content of the antiaging agent is 1.8%; the regenerant is aromatic oil, and the viscosity reducer is tall oil , the plasticizer is one or both of epoxidized soybean oil and hydrogenated castor oil, and the anti-aging agent is one or both of N, N'-xylyl-p-phenylenediamine and anti-aging agent RD two kinds;

[0033] Step 2, after mixing the warm mixing agent, solubilizer and composite surfactant, stir for 8 mi...

Embodiment 2

[0046] The method for preparing the warm-mix recycled asphalt mixture in this example is the same as that of Example 1, except that the plasticizer is hydrogenated castor oil, or a mixture of epoxidized soybean oil and hydrogenated castor oil, and the plasticizer is hydrogenated castor oil. The aging agent is anti-aging agent RD, or a mixture of N, N'-xylyl-p-phenylenediamine and anti-aging agent RD;

[0047] The warm mixing agent is polyethylene wax or microcrystalline wax, or two or three of polyethylene wax, oxidized polyethylene wax and microcrystalline wax; the melting range of the polyethylene wax is preferably 100° C. to 110° C. ℃.

Embodiment 3

[0049] The gradation type of the warm-mix recycled asphalt mixture prepared in this example is AC-25, and the target gradation is shown in Table 1. The specific preparation method includes the following steps:

[0050] Step 1. After mixing the regenerant, viscosity reducer, plasticizer and antiaging agent, melt and shear for 8 minutes at a temperature of 175° C. to obtain a composite regenerant; the mass content of the regenerant in the composite regenerant is 67%, the mass content of the viscosity reducer is 30%, the mass content of the plasticizer is 1.4%, and the mass content of the antiaging agent is 1.6%; the regenerant is aromatic oil, and the viscosity reducer tall oil, The plasticizer is epoxy soybean oil, and the anti-aging agent is N, N'-xylyl-p-phenylenediamine;

[0051] Step 2, after mixing the warm mixing agent, solubilizer and composite surfactant, stir for 8 minutes at a temperature of 120° C. to obtain a composite warm mixing agent; the mass content of the warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com