Environment protection buckling press through-combining type antiseismic wall structure

A wall structure and environmental protection technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of waste of resources, impact resistance, and high production costs, and achieve simple construction, convenient installation and disassembly, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

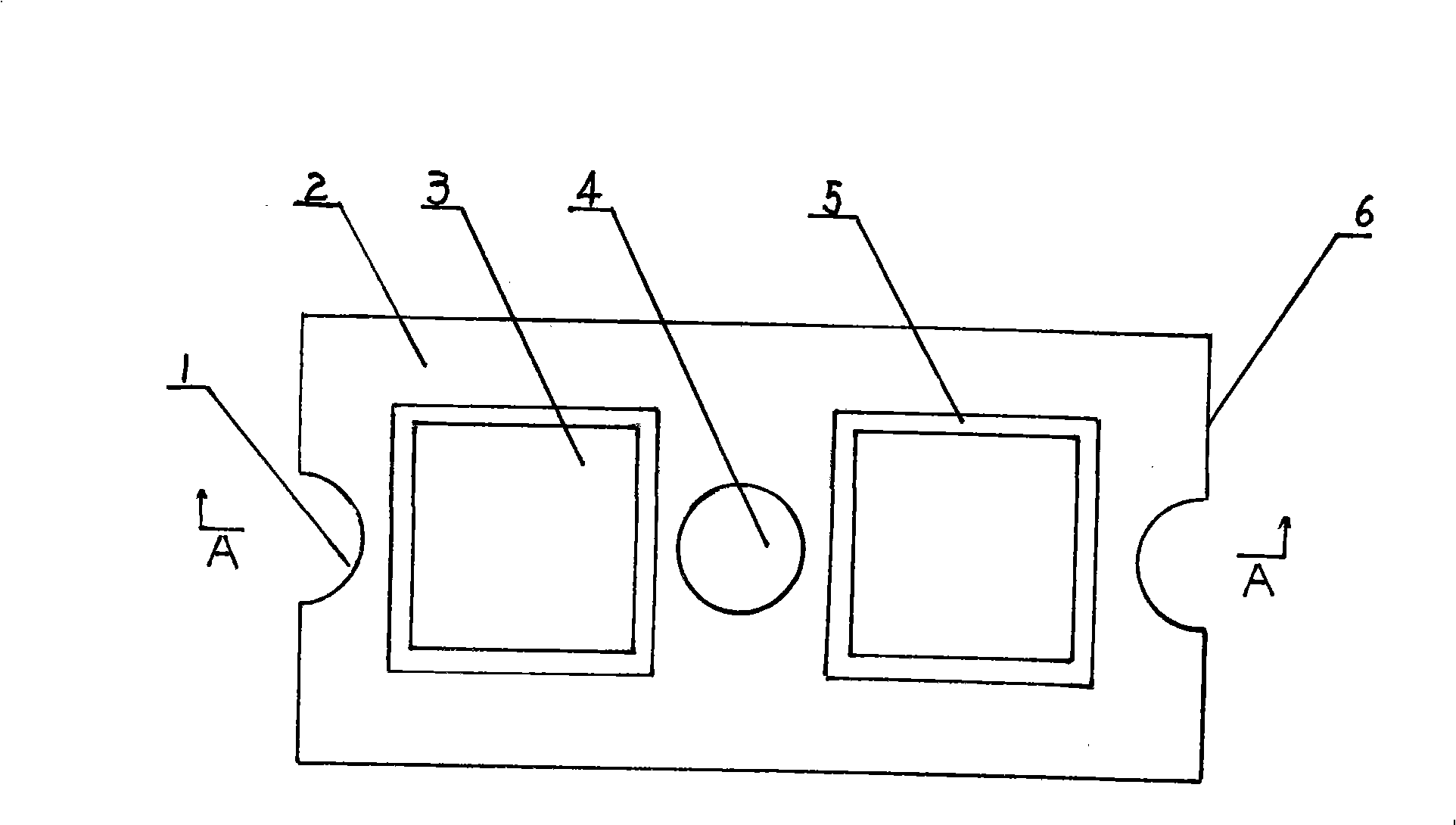

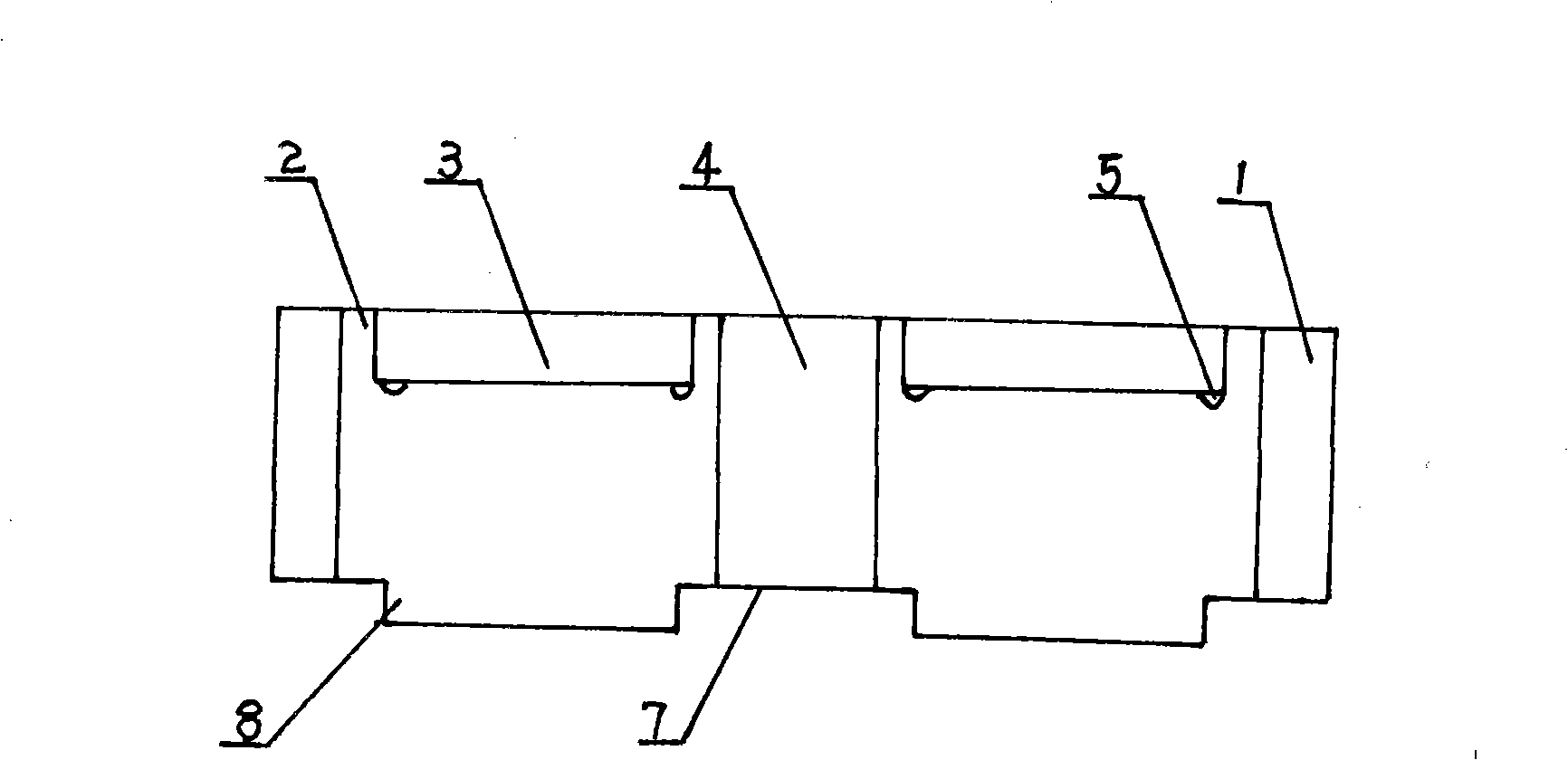

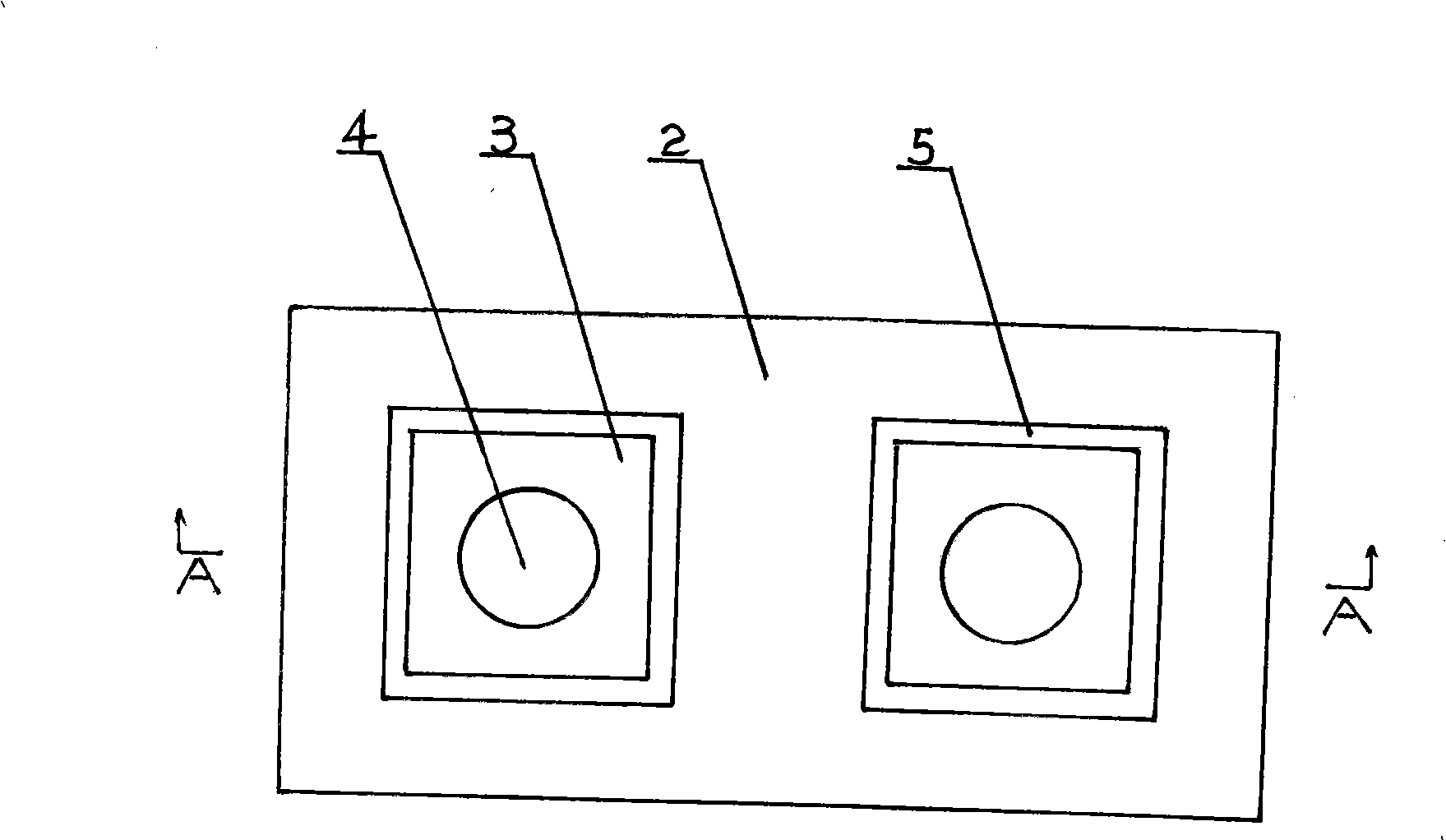

[0013] Such as Figure 1 to Figure 7 As shown, an environment-friendly buckle-fit type seismic wall structure is mainly composed of buckle-type bricks and reinforcement ribs. The buckle-type bricks are composed of brick top 2, brick side 6 and brick bottom 7. The buckle-through type brick is provided with a piercing hole 4 that runs through the upper surface of the brick and the lower surface of the brick, the upper surface of the brick is provided with a groove 3, and the lower surface of the brick is provided with a card protrusion 8 for being inserted into the groove; The lower end and the foundation reinforcement in the foundation are fixed into one structure, or directly fixed as a whole with the foundation. The spacing of each reinforcing bar is set according to the spacing between the piercing holes, and the reinforcing bars are threaded into each brick piercing hole, followed by The bricks are staggered to form the wall structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com