Cutting and jointing device for automatic grafting of seedlings

An automatic grafting and joining device technology, applied in the field of cutting and joining devices, can solve the problems affecting grafting efficiency, high processing and assembly costs, and long time intervals, and achieve the effects of improving grafting efficiency, reducing equipment costs, and improving survival rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with embodiment, further illustrate the present invention.

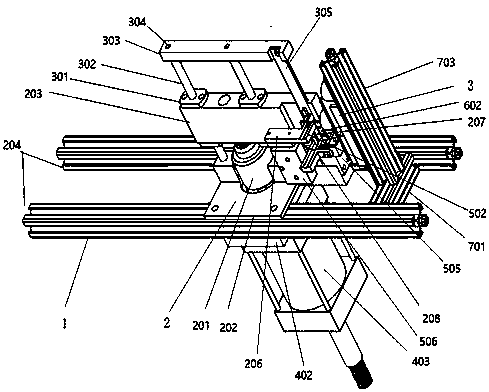

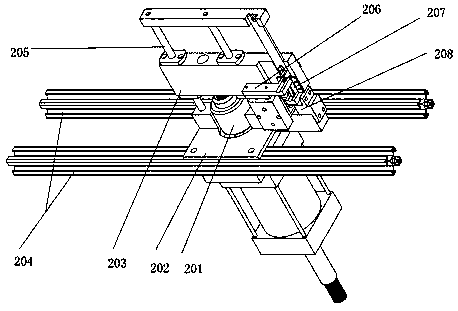

[0041] see figure 1 , figure 2 and Figure 7 , a kind of cutting joint mechanism 2 that is used for seedling automatic grafting of the present invention comprises support 1, cutting joint mechanism 2, stock moving mechanism 3, is characterized in that: described support 1 is made of two longitudinal beams 204, a crossbeam 701 and a vertical beam 703, each beam is made of standard aluminum profiles and connected by aluminum alloy corner fittings. The cutting joint mechanism 2 is provided with a fixed seat 202 , a moving seat 203 , a moving drive assembly 201 , a moving guide assembly 205 , a rootstock support assembly 208 , an earwood support assembly 206 and a grafting knife assembly 207 .

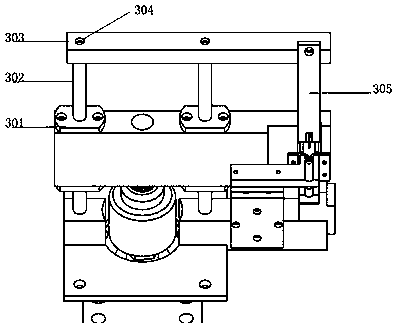

[0042] see figure 2 , image 3 and Figure 4 , the fixed seat 202 is installed on the upper side of the longitudinal beam 204 of the support 1, and two guide post installation holes 304 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com