Processing method for engine crankshaft vibration damping pulley wheel hub with end surface rat fluted disc

A processing method, rattooth disc technology, applied in the field of crankshaft pulleys, can solve problems such as inability to effectively achieve easy assembly of the end of the crankshaft, failure to ensure the accuracy of the end of the crankshaft, and affect the accuracy of signal acquisition, etc., to achieve light weight, simple manufacturing process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

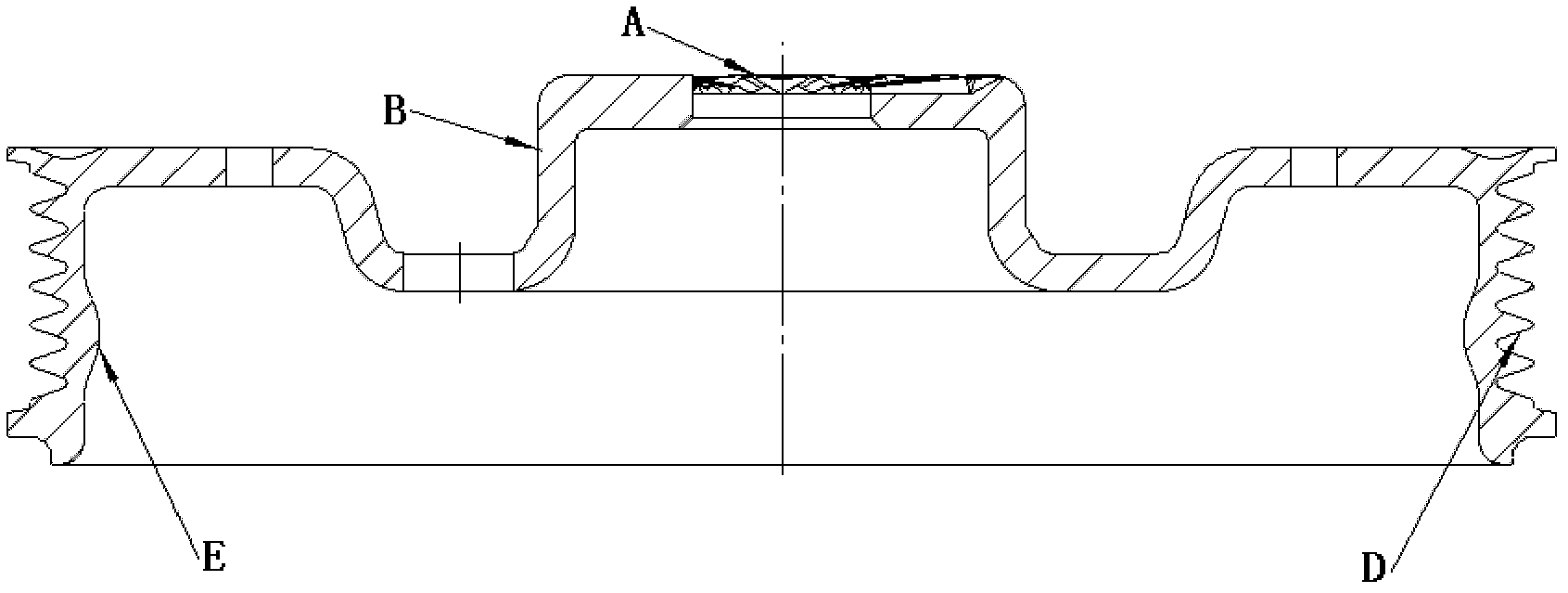

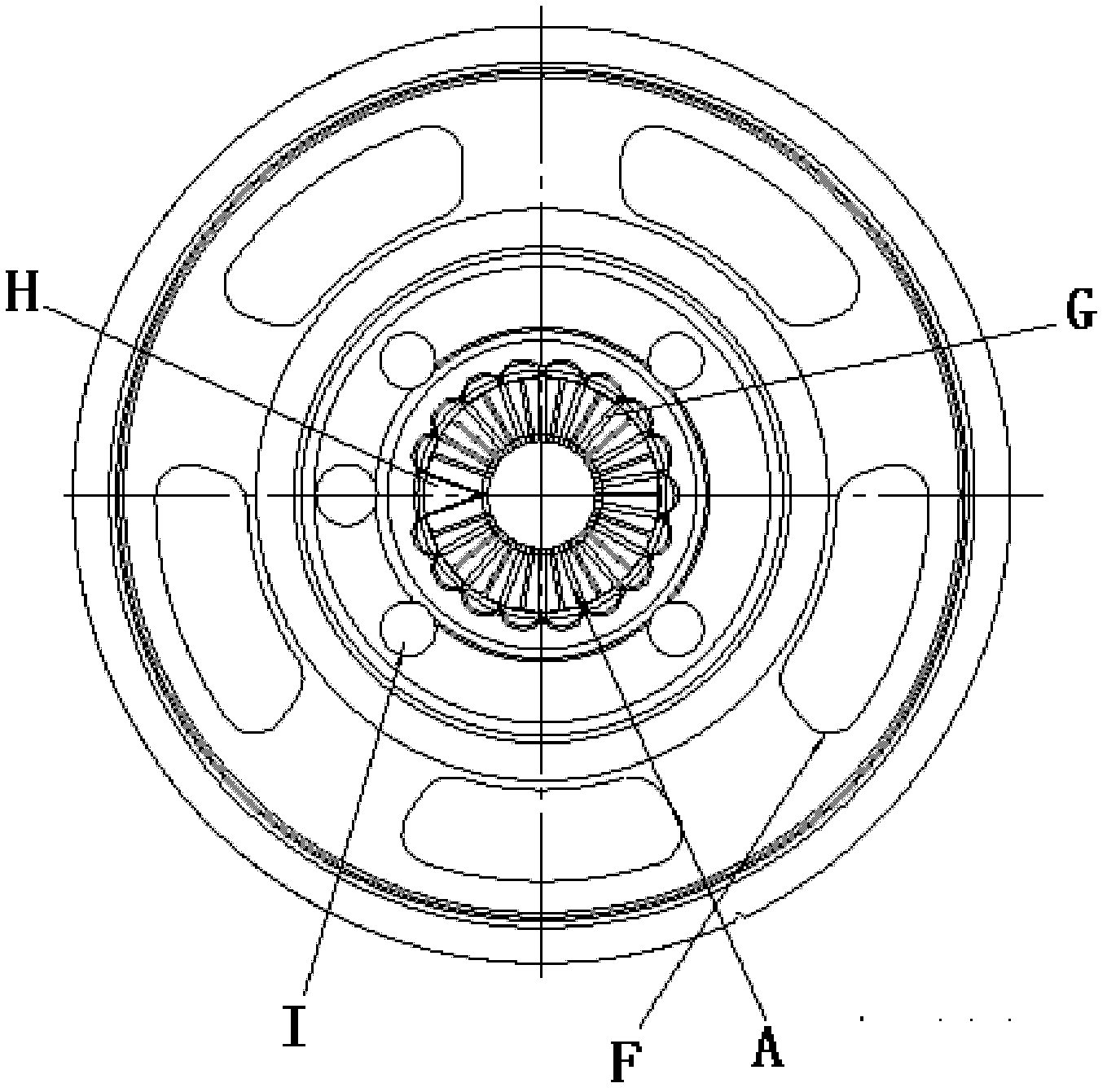

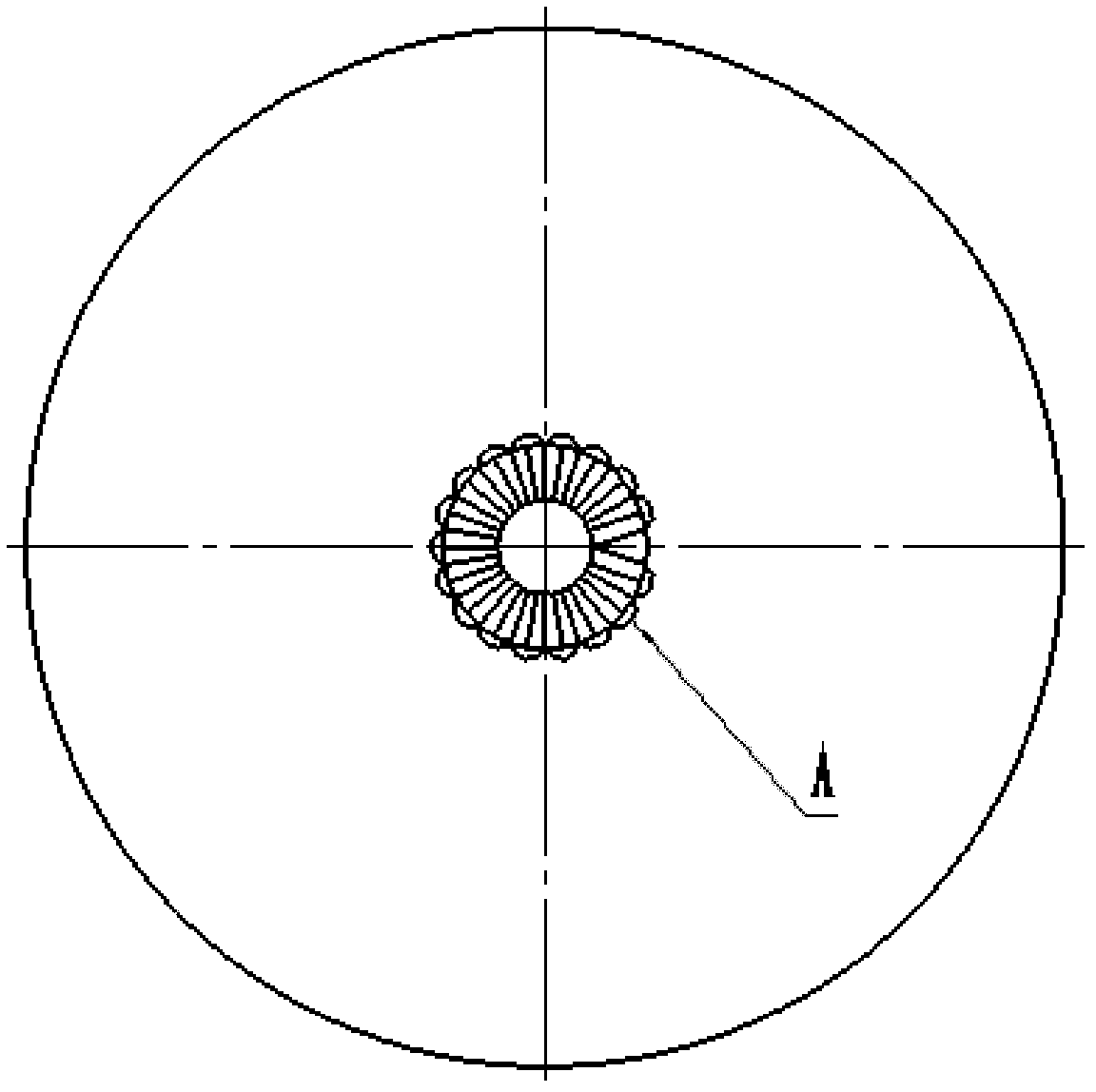

[0022] Such as figure 1 , figure 2 As shown, the product processed by the present invention includes an end-face rat tooth plate A, a columnar assembly surface B, a poly-wedge tooth D, an inner wall with an anti-slip protrusion annular assembly surface E, a mounting hole and a process hole F, wherein the end-face rat There are 17 mouse teeth G uniformly distributed at 20° on the disc A, and one mouse tooth G is missing on the 360° circumferential surface.

[0023] The processing method of the present invention is as follows: firstly, the most important end ratchet plate is spun out on the circular sheet material through the end face spinning technology, and then through further spinning, machining and punching processes, the engine crankshaft vibration damping plate is finally processed. The finished product of the pulley hub, the specific steps are as follows:

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com