Impeller assembly machine for multi-blade centrifugal fan

A centrifugal fan, multi-blade technology, applied in the direction of machines/engines, mechanical equipment, non-variable-capacity pumps, etc., can solve the problems of low production efficiency, long time, affecting the quality of impellers, etc., to improve assembly quality, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

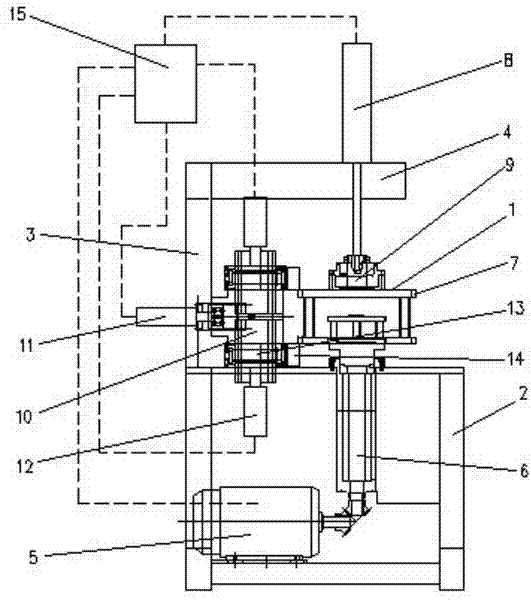

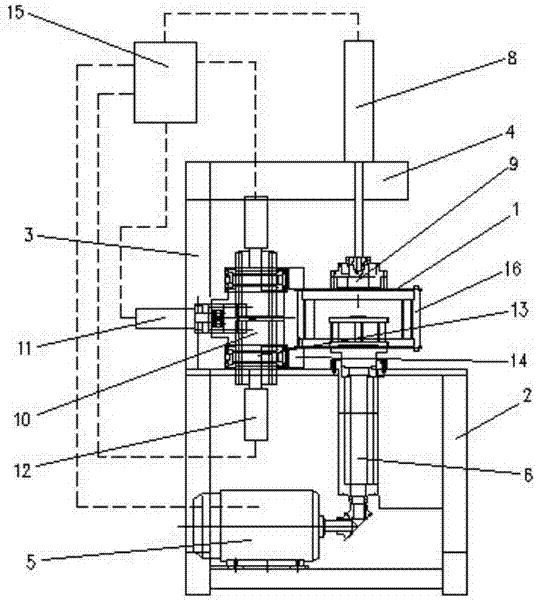

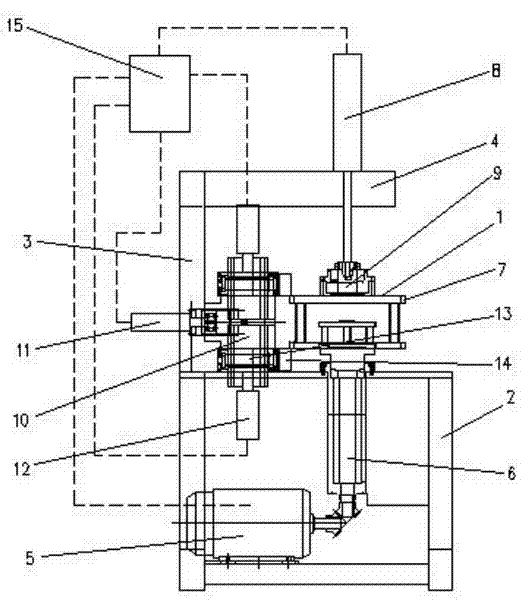

[0013] Such as figure 1 As shown, the present invention discloses a multi-blade centrifugal fan impeller assembly machine, its innovation mainly lies in that it includes a workbench 2 and a column 3 vertically fixed on the workbench 2 and a beam 4 fixed on the column 3 , there is a power unit 5 and a vertically placed main shaft 6 connected to the power unit 5 in the workbench 2, an impeller mold 1 is detachably connected to the main shaft 6, and the impeller mold 1 is located on the workbench 2 usually the power unit 5 can be an electric motor, because the electric motor is usually placed horizontally, and the main shaft 6 is placed vertically, so the electric motor and the main shaft 6 can be connected through bevel gear transmission. The impeller mold 1 should match the specifications of the impeller to be assembled. Since the impeller mold 1 and the main shaft 6 are connected in a detachable manner, various impeller molds 1 can be replaced by different specifications. Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com