Stem block plant smashing device

A crushing device and plant technology, which is applied in the field of mechanical processing devices, can solve the problems of low utilization rate of stem plant processing and insufficient recycling and reprocessing functions, and achieve the effect of simple structure, strong practicability, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

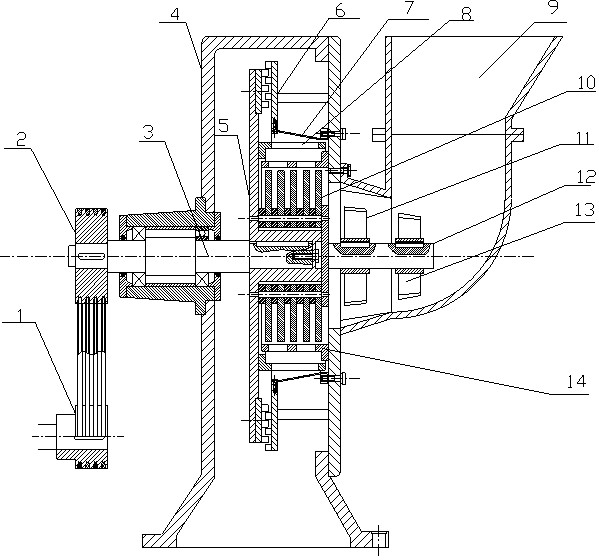

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, a kind of stem plant crushing device of the present invention includes a motor and a body 4 that provide power, the motor is connected with the small pulley 1, the small pulley 1 is connected with the large pulley 2 by a belt, and the large pulley 2 is connected by a key Connected to the main shaft 3, the body 4 is provided with a cavity, and one end of the main shaft 3 in the cavity is covered with a movable toothed disc 5, and the movable toothed disc 5 is provided with a cylindrical boss, and a hammer 10 is set on the cylindrical boss. The sheet 10 is provided with a rotating screen drum 8 installed on the movable toothed disc 5, and a coarse screen drum 14 fixed on the machine body 4 is provided between the rotating screen drum 8 and the hammer 10, and the rotating screen drum 8 is provided with a Tapered fine sieve cylinder 7, on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com