Combined-drawer-type floating breakwater

A floating breakwater, drawer-type technology, applied in the direction of breakwaters, jetties, embankments, etc., to facilitate maintenance, reduce drag resistance, and maintain the effect of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

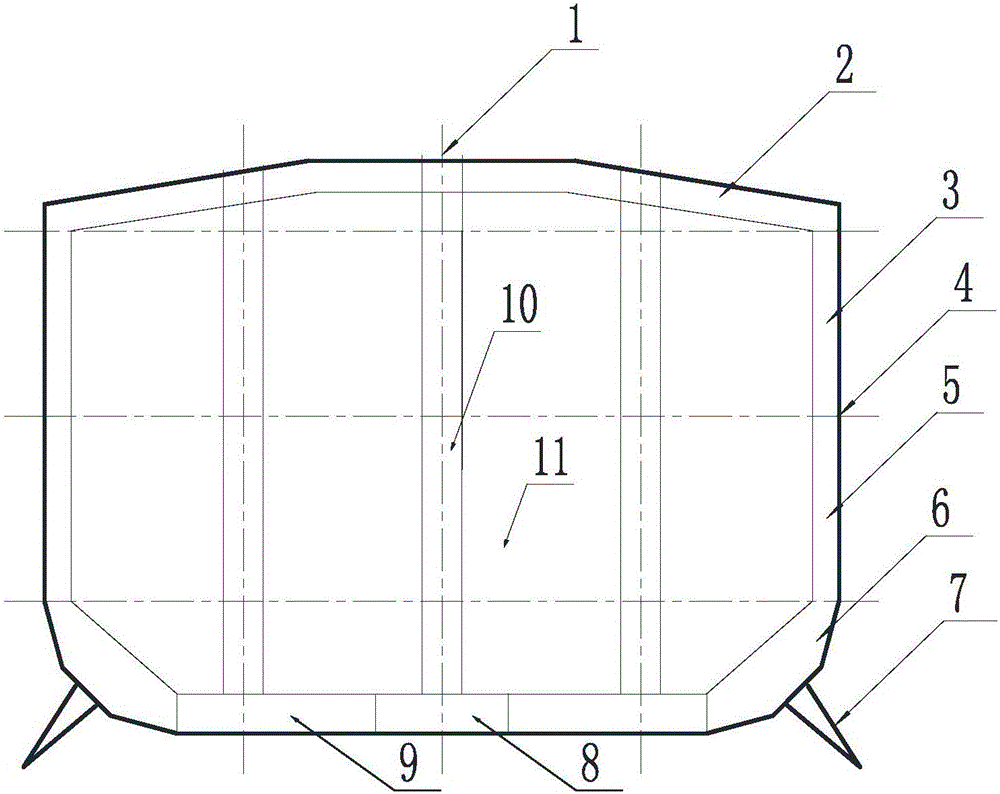

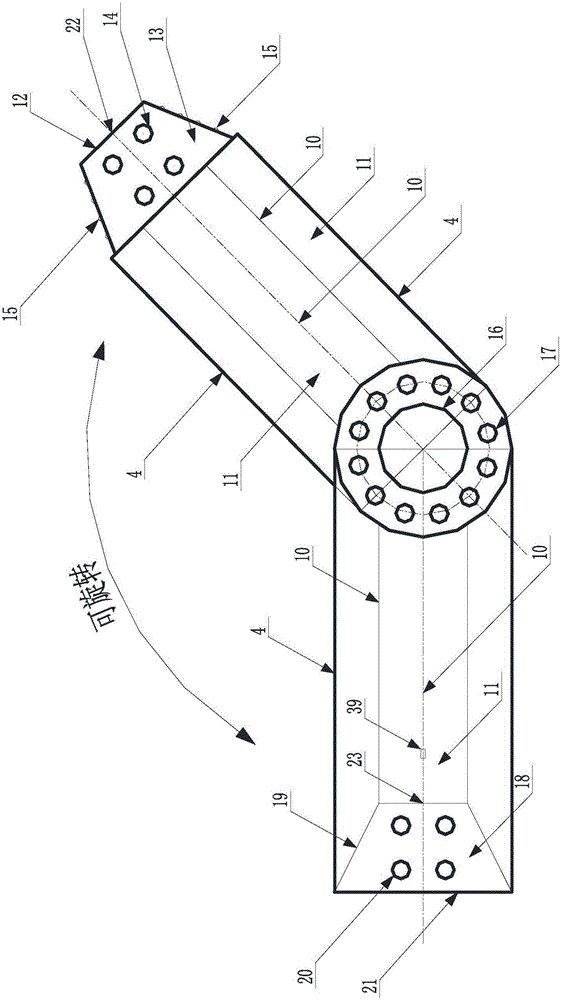

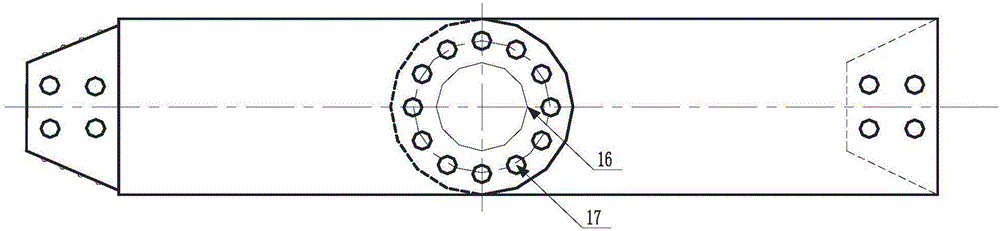

[0036] The present invention will be further described below in conjunction with drawings and embodiments.

[0037] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention comprises a plurality of monomers with the same structure, and each monomer includes two casings, a male and a female; one end of the two casings of the male and female is hinged by a hinge 16, and the other end of the male casing is hinged. The drawer-type male splicing interface 13 is spliced with the drawer-type female splicing interface 18 at one end of the adjacent female box, and the drawer-type female splicing interface 18 at the other end of the female box is spliced with the drawer-type male splicing interface 13 at one end of the adjacent male box. A strip-shaped floating breakwater is formed by splicing a plurality of monomer boxes end to end; the shape of the floating breakwater can be changed by changing the angle between the hinges 16; the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com