AC hanging-type composite insulator

A composite insulator and suspension technology, which is applied in the direction of suspension/strain insulators, can solve the problems of poor pollution flashover resistance and other problems, and achieve the effects of avoiding waste, excellent pollution flashover resistance, and product weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

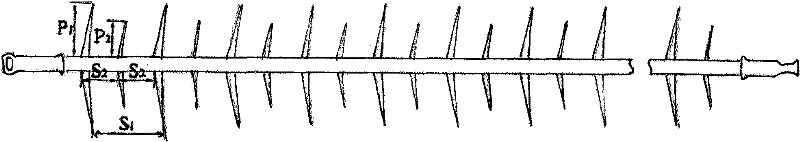

[0023] Such as figure 1 As shown, the insulator of the present invention is an AC suspension composite insulator, including a mandrel, metal fittings provided at both ends of the mandrel, a sheath covering the mandrel, and a large umbrella with the same diameter as the mandrel. And a small umbrella is set between each adjacent large umbrella, the diameter of the shed of the small umbrella is equal, the distance between the two adjacent umbrellas is 97.5mm ~ 102.5mm, the ratio of the umbrella extension of the large umbrella to the umbrella extension of the small umbrella It is 1.2~1.3, and the average umbrella extension is 71mm~76mm, and the creepage coefficient is 3.5~4.0. Average Umbrella Extended P av It's a big umbrella that sticks out P 1 And the umbrella of the small umbrella sticks out P 2 The mean value of , that is, Pav=(P 1 +P 2 ) / 2.

Embodiment 2

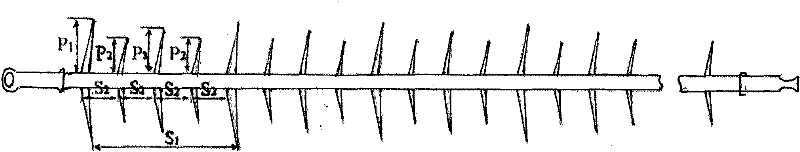

[0025] Such as figure 2 As shown, another insulator of the present invention is an AC suspension composite insulator, including a mandrel, metal fittings provided at both ends of the mandrel, a sheath covering the mandrel, and a diameter equal to the coaxial diameter of the mandrel. The large umbrella and the middle umbrella and the small umbrella between each adjacent large umbrella, the above-mentioned adjacent large umbrellas are arranged according to a small umbrella, a middle umbrella, and a small umbrella, and the diameters of the sheds of the middle umbrellas are equal, so The diameters of the umbrella skirts of the small umbrellas are equal. The distance between adjacent large umbrellas is 210mm~220mm; the ratio of the umbrella extension of the large umbrella to the umbrella extension of the middle umbrella is 1.2~1.3, and the ratio of the umbrella extension of the large umbrella to the umbrella extension of the small umbrella is 1.7~1.8 , and the average umbrella ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com