A kind of waterborne fluorocarbon antifouling flashover coating and its preparation method and application

An anti-pollution flashover coating, water-based fluorocarbon technology, applied in anti-fouling/underwater coatings, anti-corrosion coatings, coatings, etc., to achieve the effect of improving self-cleaning performance, improving hydrophobicity, and preventing pollution flashover accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

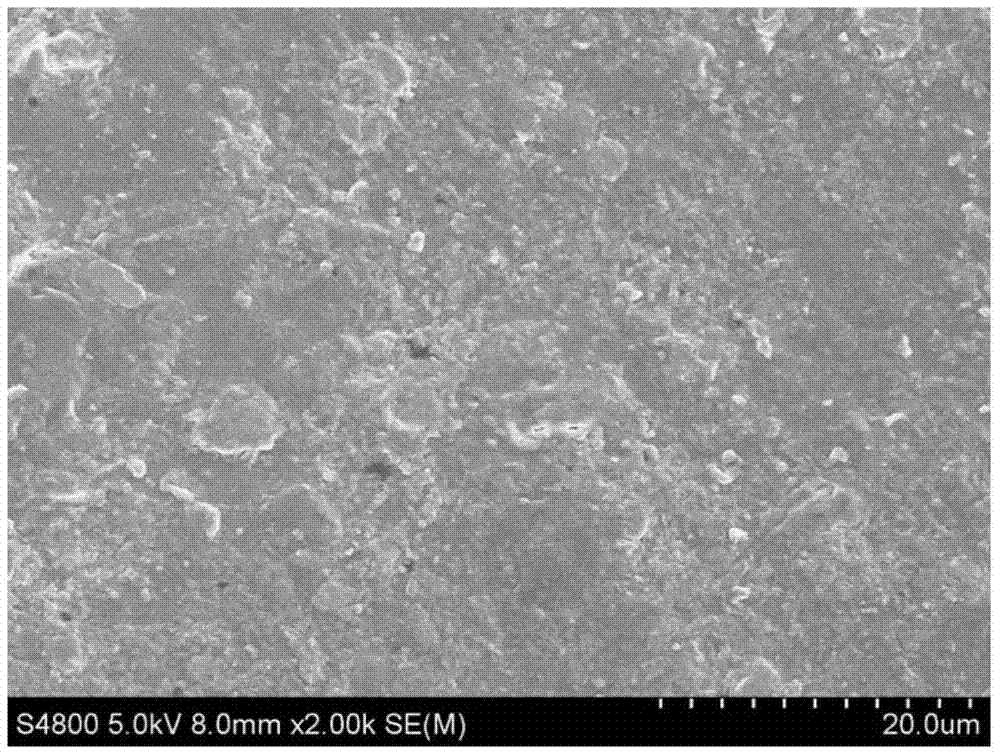

Embodiment 1

[0045] A water-based fluorocarbon antifouling flashover coating of the present invention, each component is water-based material, including the following components in terms of mass percentage: 50% fluorocarbon emulsion, 25% water, 10% nano functional filler, 0.8% dispersant , film-forming aid 3%, thickener 0.8%, leveling agent 0.3%, defoamer 0.4%, fungicide 0.4%, pH regulator 1%, propylene glycol 8% and curing agent 0.3%.

[0046] In this embodiment, the fluorocarbon emulsion is a water-based fluorocarbon emulsion, the nano-functional filler is a water-based nano-functional filler, the dispersant is a water-based dispersant; the film-forming aid is a water-based film-forming aid; the thickener is a water-based thickener; The leveling agent is a water-based leveling agent; the defoamer is a water-based defoamer; the bactericide is a water-based bactericide; the curing agent is a water-based curing agent.

[0047] In this example, the water-based fluorocarbon emulsion is DF-01 ...

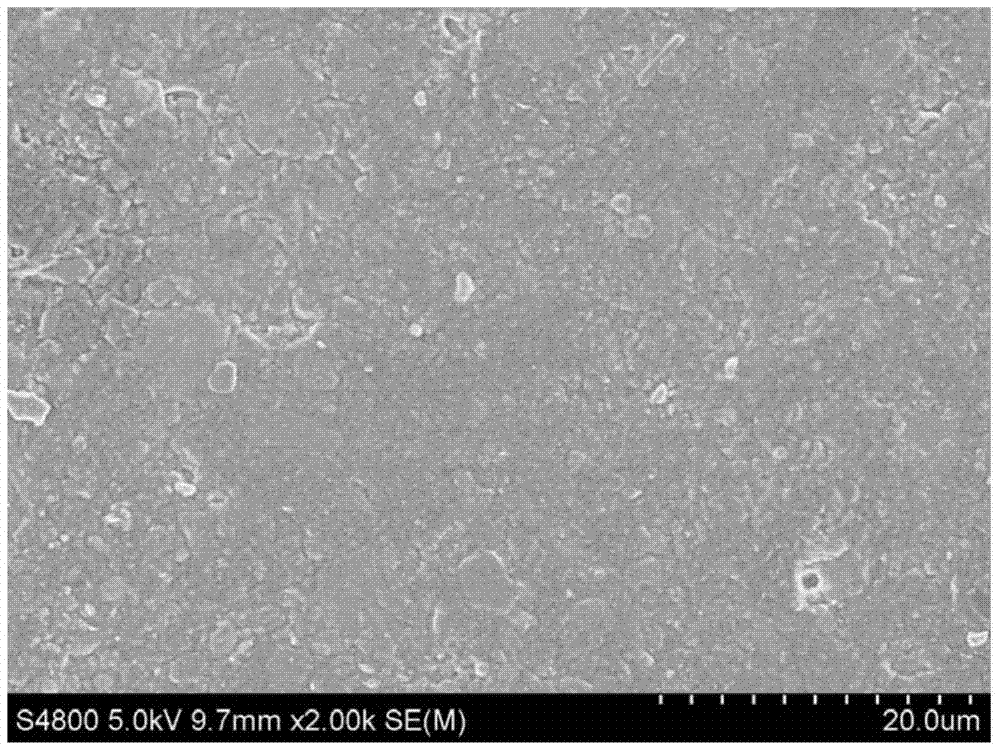

Embodiment 2

[0071] A water-based fluorocarbon anti-fouling flashover coating of the present invention, each component is a water-based material, including the following components in terms of mass percentage: 45% fluorocarbon emulsion, 20% water, 20% nano functional filler, 0.8% dispersant , film-forming aid 3%, thickener 0.8%, leveling agent 0.3%, defoamer 0.4%, fungicide 0.4%, pH regulator 1%, propylene glycol 8% and curing agent 0.3%.

[0072] In this embodiment, the fluorocarbon emulsion is a water-based fluorocarbon emulsion, the nano-functional filler is a water-based nano-functional filler, the dispersant is a water-based dispersant; the film-forming aid is a water-based film-forming aid; the thickener is a water-based thickener; The leveling agent is a water-based leveling agent; the defoamer is a water-based defoamer; the bactericide is a water-based bactericide; the curing agent is a water-based curing agent.

[0073] In this embodiment, the water-based fluorocarbon emulsion is ...

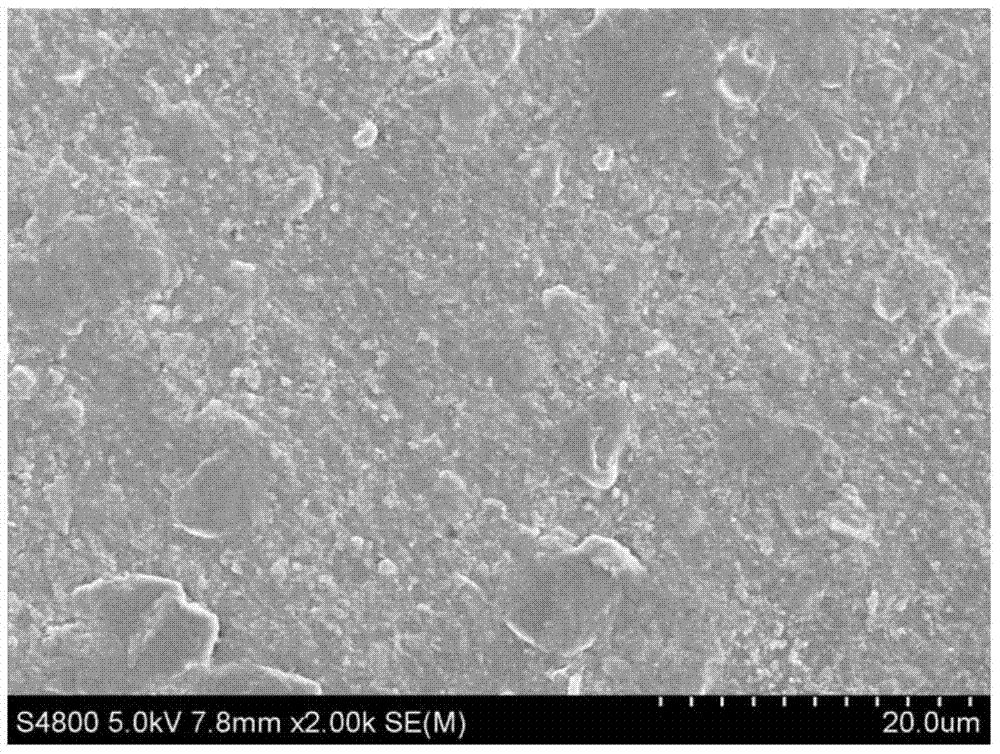

Embodiment 3

[0090] A water-based fluorocarbon anti-fouling flashover coating of the present invention, each component is a water-based material, including the following components in terms of mass percentage: 40% fluorocarbon emulsion, 15% water, 30% nano functional filler, 0.8% dispersant , film-forming aid 3%, thickener 0.8%, leveling agent 0.3%, defoamer 0.4%, fungicide 0.4%, pH regulator 1%, propylene glycol 8% and curing agent 0.3%.

[0091] In this embodiment, the fluorocarbon emulsion is a water-based fluorocarbon emulsion, the nano-functional filler is a water-based nano-functional filler, the dispersant is a water-based dispersant; the film-forming aid is a water-based film-forming aid; the thickener is a water-based thickener; The leveling agent is a water-based leveling agent; the defoamer is a water-based defoamer; the bactericide is a water-based bactericide; the curing agent is a water-based curing agent.

[0092] In this embodiment, the water-based fluorocarbon emulsion is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com