Expansion joint regulator element and expansion joint regulator made therefrom

A regulator and expansion joint technology, applied in bridge parts, bridges, buildings, etc., can solve problems such as unfavorable popularization and application, complex structure, and large maintenance volume, and achieve the effect of facilitating popularization and application, improving mechanical properties, and reducing self-weight load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

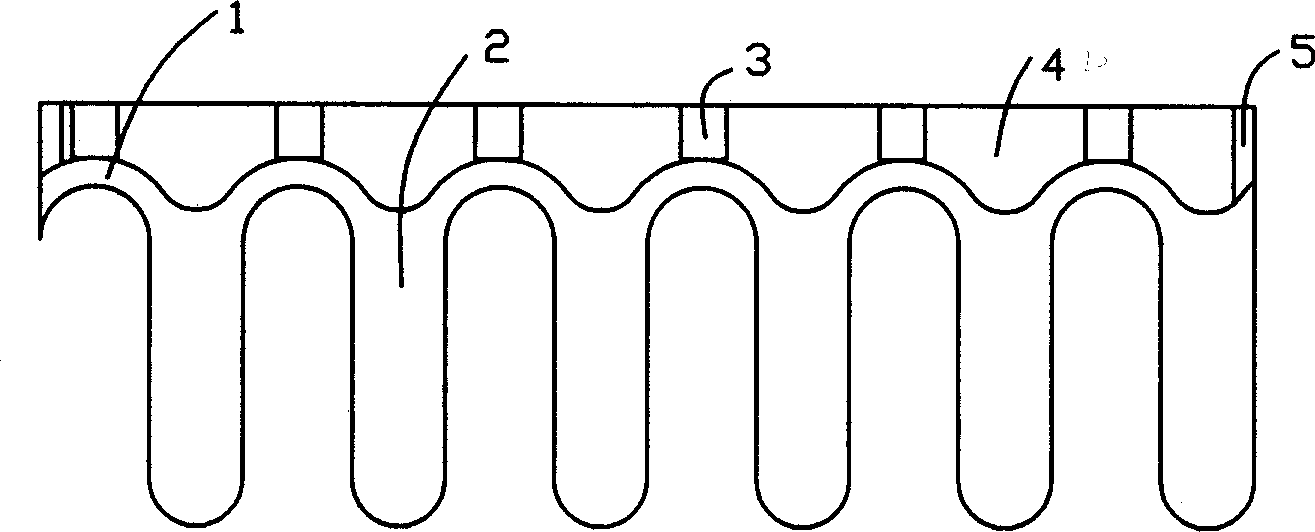

[0025] Such as figure 1 The shown expansion joint adjuster component is composed of a telescopic back 1 and a telescopic beam 2 that is equidistant from one side of the telescopic back 1 and is uniformly casted. The telescopic beams are equal in length, parallel to each other, and perpendicular to the telescopic back. The top and bottom planes of the telescopic back 1 coincide with the top and bottom planes of the telescopic beams 2. The cross-section of each telescopic beam is an "I"-shaped structure with the same width at the bottom and top, such as Figure 5 shown. The width of each telescopic beam is smaller than the distance between each other. On the outer back of the telescopic back, there are evenly fixed threaded joints 3 for connecting the embedded connecting rods. In order to facilitate the fixed connection of two adjacent components, the two ends of each component are provided with fixing ears 5 with bolt holes 8. Such as Figure 4 As shown, at the same time, i...

Embodiment 2

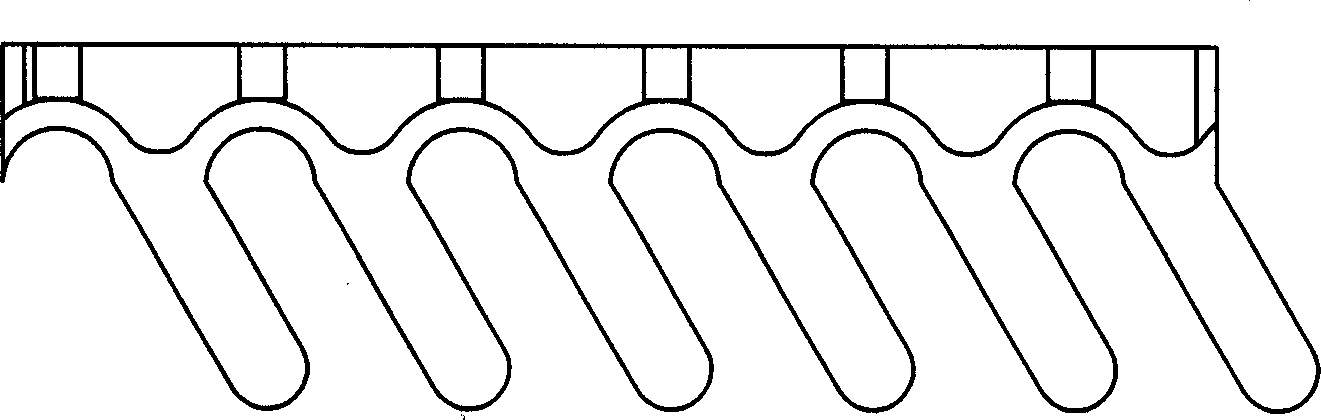

[0027] Such as figure 2 As shown, the basic structure of this embodiment is the same as that of Embodiment 1, the difference is that in order to meet some specific requirements for use, the stretching direction of the telescopic beam is deflected to the right to form an angle less than 90° with the telescopic back , which is set to 30° in this embodiment.

Embodiment 3

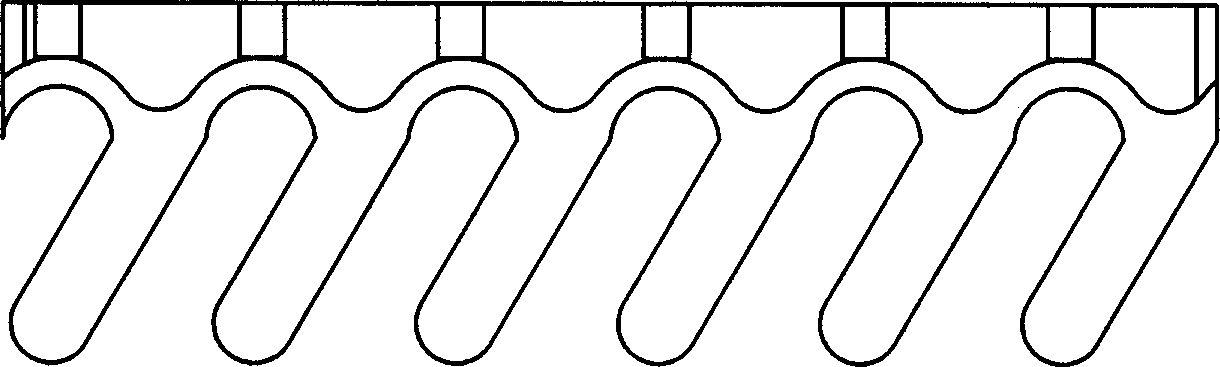

[0029] Such as image 3 As shown, its basic structure is still the same as that of Embodiment 1. For the same consideration as Embodiment 2, in order to meet some specific requirements for use, the stretching direction of the telescopic beam is deflected to the left and the telescopic back forms a less than 90 ° angle. In this embodiment, it is set to 30°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com