Permanent magnet for loudspeaker and processing technology thereof

A processing technology and permanent magnet technology, applied in the field of permanent magnets and their processing technology, can solve the problems of loudspeaker maintenance and overall performance impact, loose permanent magnet grain structure, easy distortion of loudspeaker sound, etc., to achieve wide application range and convenience Long-term use, high coercivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

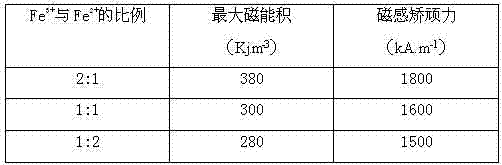

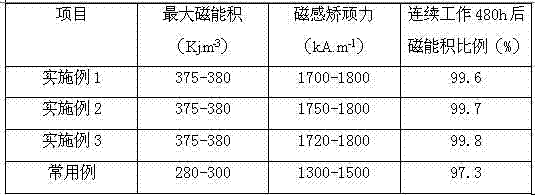

[0018] Embodiment 1: a kind of permanent magnet for loudspeaker, the weight ratio of each component in the described permanent magnet is: 10% neodymium, 1.5% calcium carbonate, 2.2% titanium, 8% zinc oxide, 2% Boron, 3% aluminum oxide, 0.2% gallium, and the balance is iron oxide, which contains ferric iron and ferrous iron, and the mol ratio of ferric iron and ferrous iron is 2:1, Add cerium-iron alloy to the product, the weight ratio of different trace elements in the cerium-iron alloy to iron is 1:1, the average diameter of the particles of the cerium-iron alloy is 4um-6um, and the amount of the alloy metal is 1% of the total mass of the permanent magnet. 0.03%-0.08%.

[0019] During the oxidation process, put the iron powder into the reaction kettle containing water vapor for reaction, gradually raise the temperature to 400°C, weigh the weight of iron oxide every 10 minutes during the oxidation process, until the weight does not change after weighing three times, stop the o...

Embodiment 2

[0025] Embodiment 2: a kind of permanent magnet for loudspeaker, the weight ratio of each component in the described permanent magnet is: 14.5% neodymium, 2.4% calcium carbonate, 2.6% titanium, 12.5% zinc oxide, 4.5% Boron, 4.5% aluminum oxide, 0.8% gallium, and the balance is iron oxide, which contains ferric iron and ferrous iron, and the mol ratio of ferric iron and ferrous iron is 2:1, The yttrium-iron alloy is added to the product, the weight ratio of different trace elements in the yttrium-iron alloy to iron is 1:1, the average diameter of the particles of the yttrium-iron alloy is 4um-6um, and the amount of the alloy metal is 1% of the total mass of the permanent magnet. 0.03%-0.08%.

[0026] During the oxidation process, put the iron powder into the reaction kettle containing water vapor for reaction, gradually raise the temperature to 400°C, weigh the weight of iron oxide every 10 minutes during the oxidation process, until the weight does not change after weighing ...

Embodiment 3

[0032] Embodiment 3: a kind of permanent magnet for loudspeaker, the weight ratio of each component in the described permanent magnet is: 12% neodymium, 2.1% calcium carbonate, 2.4% titanium, 10% zinc oxide, 3% Boron, 4% aluminum oxide, 0.6% gallium, and the balance is iron oxide, which contains ferric iron and ferrous iron, and the mol ratio of ferric iron and ferrous iron is 2:1, Lutetium-iron alloy is added to the product. The weight ratio of different trace elements in the lutetium-iron alloy to iron is 1:1, the average diameter of the particles of the lutetium-iron alloy is 4um-6um, and the amount of the alloy metal is 0.03%-0.08% of the total mass of the permanent magnet.

[0033] During the oxidation process, put the iron powder into the reaction kettle containing water vapor for reaction, gradually raise the temperature to 400°C, weigh the weight of iron oxide every 10 minutes during the oxidation process, until the weight does not change after weighing three times, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com