Permanent magnet for loudspeaker and preparation method thereof

A permanent magnet, speaker technology, applied in the direction of magnets, inductors/transformers/magnets, magnetic objects, etc., can solve problems affecting the service life and performance of speakers, low density and structural strength of iron oxide magnets, maximum magnetic energy product and magnetic induction. The problems of low coercivity and low cost of raw materials can achieve the effect of low cost of raw materials, low requirements for production conditions, and improved magnet density and structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

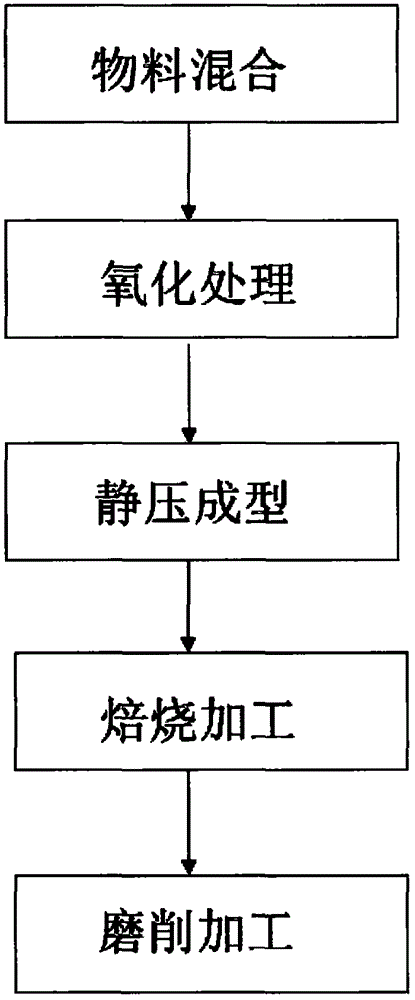

[0020] Such as figure 1 A permanent magnet for loudspeaker is shown, each component and the mass ratio between components are: 1.5% neodymium, 3% titanium, 5% boron, 3% kaolin, and the balance is iron oxide.

[0021] In this embodiment, the iron ions of the iron oxide are a mixture of ferric ions and ferric ions, wherein the ratio of ferric ions to ferric ions is 1:2.

[0022] In this embodiment, the neodymium, titanium, boron, kaolin and iron oxide are all powder structures, and the particle size is 90 mesh.

[0023] A preparation method for a permanent magnet for a loudspeaker, comprising the steps of:

[0024] The first step is to mix the materials. First, add neodymium, titanium, boron and kaolin to the iron oxide powder in proportion, and fully stir and mix evenly;

[0025] In the second step, oxidation treatment, the mixed raw materials are mixed with oxygen with a purity of 80% and passed into the oxidation furnace for high-temperature oxidation treatment. The oxidati...

Embodiment 2

[0031] Such as figure 1 A permanent magnet for a loudspeaker is shown, each component and the mass ratio between components are: 1.5% neodymium, 3% titanium, 5% boron, 3% yttrium-iron alloy, 3% kaolin, and the balance is iron oxide.

[0032] In this embodiment, the iron ions of the iron oxide are a mixture of ferric ions and ferric ions, wherein the ratio of ferric ions to ferric ions is 1:2.

[0033] In this embodiment, the neodymium, titanium, boron, kaolin, yttrium-iron alloy and iron oxide are all powder structures with a particle size of 100 mesh.

[0034] A preparation method for a permanent magnet for a loudspeaker, comprising the steps of:

[0035] The first step is to mix the materials. First, add neodymium, titanium, boron, yttrium-iron alloy and kaolin to the iron oxide powder in proportion, and fully stir and mix evenly;

[0036] In the second step, oxidation treatment, the mixed raw materials are mixed with oxygen with a purity of 80% and passed into the oxidati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com