Sintered magnet motor

A technology of sintered magnets and motors, which is applied in the direction of electric components, magnetic circuit rotating parts, magnetic circuits, etc., can solve the problems of no residual magnetic flux density, no composite magnets, etc. The effect of increased stamina

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]The Fe-10% Co powder is made by water atomization method, and the average particle size is 10 μm. Contains oxygen near the surface. When the amount of oxygen is 500 ppm or more, fluoride is formed on the surface of the Fe-10%Co powder, and then oxyfluoride grows. This oxyfluoride is represented by RExOyFz (RE is a rare earth element, O is oxygen, F is fluorine, and x, y, and z are positive integers), and contains inevitable elements such as carbon and nitrogen as impurities. Oxyfluoride is formed by coating the surface of water atomized powder with an alcohol solution containing fluoride and oxygen, heating it to 350-900°C, and cooling it rapidly at 10°C / sec.

[0049] After mixing the oxyfluoride-coated atomized powder and the NdFeB-based powder at a mixing ratio of 2:8, after performing magnetic field forming at room temperature (0.5t / cm 2 , 10kOe), and then preformed in a magnetic field above the Curie point of the NdFeB powder. By preforming in a magnetic field at ...

Embodiment 2

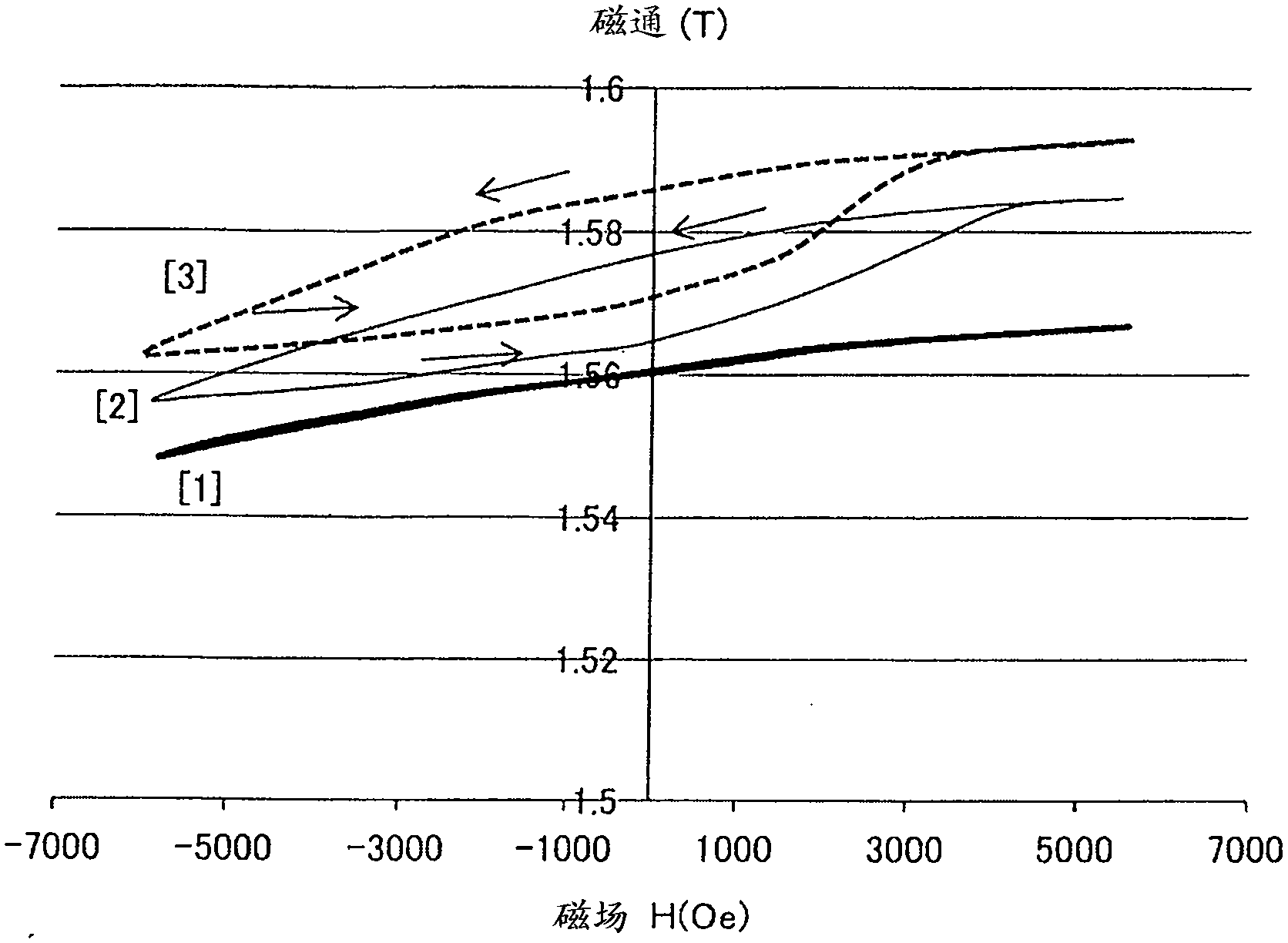

[0064] The sintered magnet of the present example is formed inside with Nd 2 Fe 14 The value of the B-based crystal is larger than that of the Fe-based crystal, and anisotropy is observed in the arrangement of the Fe-based crystal grains. The sintered magnet has the following characteristics: the main phase and only Nd 2 Fe 14 Compared with the sintered magnet of B series crystal, the residual magnetic flux density is higher, and the amount of rare earth elements used is less. image 3 Indicates part of its typical demagnetization curve. image 3 The horizontal axis of is the magnetic field H (Oe), and the vertical axis is the residual magnetic flux density (T).

[0065] [1] is Nd 2 Fe 14 B sintered magnet, [2] is Nd added with 3% FeCo (saturation residual magnetic flux density 1.9T) 2 Fe 14 B / FeCo composite sintered magnet, [3] is Nd with 5% FeCo (saturation residual magnetic flux density 2.0T) added 2 Fe 14 Demagnetization curve of B / FeCo composite sintered magnet....

Embodiment 3

[0073] The Fe-30%Co alloy is a foil-like powder produced by a melt quenching method. The Fe-30%Co alloy high-frequency melted in an inert gas atmosphere was sprayed onto the surface of a copper roll to obtain a plate-shaped or foil-shaped powder with a thickness of 10 μm and an average particle diameter of the major axis of 100 μm. In order to ensure magnetic properties, even if it contains various metal elements and semi-metal elements other than Fe and Co, as long as the content is within 20 atomic%, it can be compared with Nd 2 Fe 14 The saturation magnetization of the B-based crystal is higher, and the maximum energy product after sintering can be larger than that of the case where the FeCo-based alloy is not used.

[0074] Mix Fe-30% Co alloy powder with a saturation remanence flux density of 2.1T and Nd with a saturation remanence flux density of 1.5T at a mixing ratio of 1:9 2 Fe 14 The B-based powder is preformed at room temperature and then preformed at 400°C to ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com