Pure high-abundance rare earth Ce, La and Y-based multi-element nanocrystalline permanent magnet alloy and preparation

A high-abundance permanent magnet alloy technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problem that the coercivity and maximum energy product of the alloy cannot reach the optimal value at the same time, and the intrinsic magnetic properties Poor, poor thermal stability of Ce-based nanocrystalline permanent magnet alloys, etc., to alleviate the problem of unbalanced utilization of rare earths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

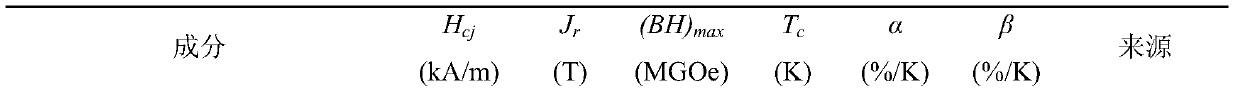

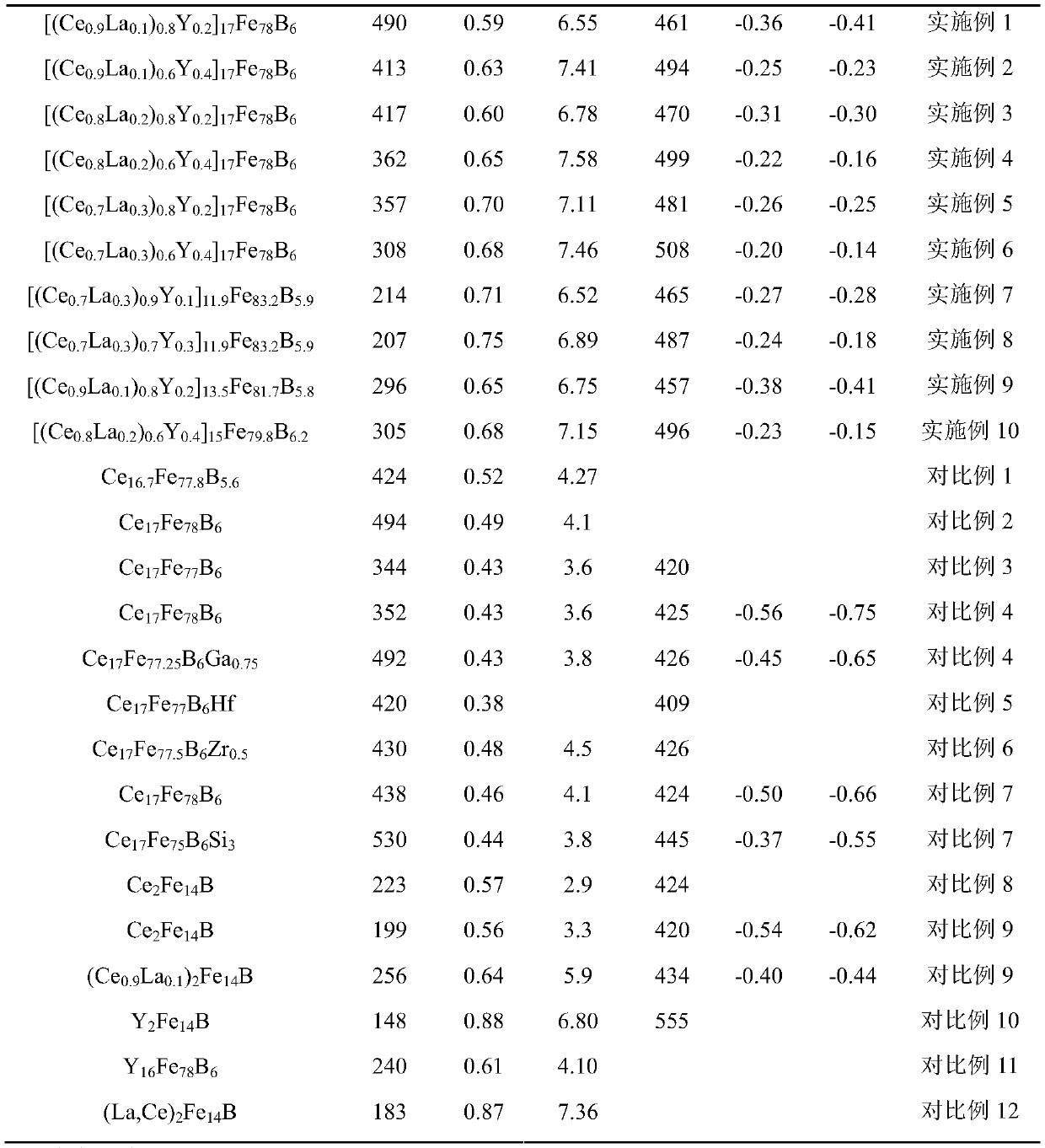

Examples

Embodiment 1

[0028] 1) Raw material preparation

[0029] Composition by atomic ratio [(Ce 0.9 La 0.1 ) 0.8 Y 0.2 ] 17 Fe 78 B 6 Prepare raw materials Ce, La, Y, Fe and FeB for later use (the purity is more than 99.8%; rare earth element raw materials Ce, La and Y need to be mechanically polished before preparation to remove rare earth oxides that may exist on the surface), each raw material weighs Quantity error is less than 0.0001%.

[0030] 2) Preparation of alloy ingots by argon arc melting

[0031] Place the prepared raw materials in an electric arc furnace, and evacuate until the vacuum degree reaches 5×10 -4 Below Pa, clean the furnace cavity with high-purity argon (Ar), repeat three times. Subsequently, high-purity argon is filled to normal pressure, and the mixed raw materials are subjected to argon arc melting under the protection of argon gas. According to the volatile degree of each element in the argon arc melting process, the order of placing each element is from the ...

Embodiment 2

[0036] 1) Raw material preparation

[0037] Composition by atomic ratio [(Ce 0.9 La 0.1 ) 0.6 Y 0.4 ] 17 Fe 78 B 6 Prepare the raw materials Ce, La, Y, Fe and FeB for later use (the purity is more than 99.8%; the rare earth element raw materials Ce, La and Y need to be mechanically polished before preparation to remove the rare earth oxides that may exist on the surface), each element weighs Quantity error is less than 0.001%.

[0038] 2) Preparation of alloy ingots by argon arc melting

[0039] Place the prepared raw materials in an electric arc furnace, and evacuate until the vacuum degree reaches 5×10 -4 Below Pa, clean the furnace cavity with high-purity argon (Ar), repeat three times. Subsequently, high-purity argon is filled to normal pressure, and the mixed raw materials are subjected to argon arc melting under the protection of argon gas. According to the volatile degree of each element in the argon arc melting process, the order of placing each element is fro...

Embodiment 3

[0044] 1) Raw material preparation

[0045] Composition by atomic ratio [(Ce 0.8 La 0.2 ) 0.8 Y 0.2 ] 17 Fe 78 B 6 Prepare the raw materials Ce, La, Y, Fe and FeB for later use (the purity is more than 99.8%; the rare earth element raw materials Ce, La and Y need to be mechanically polished before preparation to remove the rare earth oxides that may exist on the surface), each element weighs Quantity error is less than 0.001%.

[0046] 2) Preparation of alloy ingots by argon arc melting

[0047] Place the prepared raw materials in an electric arc furnace, and evacuate until the vacuum degree reaches 5×10 -4 Below Pa, clean the furnace cavity with high-purity argon (Ar), repeat three times. Subsequently, high-purity argon is filled to normal pressure, and the mixed raw materials are subjected to argon arc melting under the protection of argon gas. According to the volatile degree of each element in the argon arc melting process, the order of placing each element is fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com