Mixed paper-making reconstituted tobacco as well as preparation method and application thereof

A technology of reconstituted tobacco leaf and mixed type, which is applied in application, preparation of tobacco, and manufacture of cigars, etc. It can solve the problems of not meeting the application requirements of mixed type cigarette products, restricting the application ratio of mixed type cigarette formula, and insufficient air-drying tobacco flavor, etc. Achieve the effects of improving the uniformity of beating, increasing the soaking time, and reducing the amount of knife feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

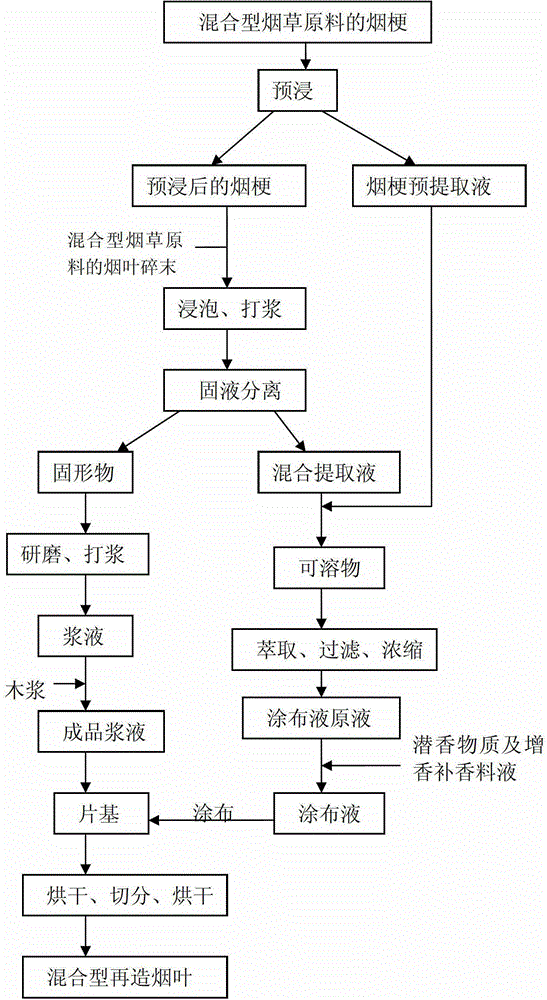

Method used

Image

Examples

Embodiment 1

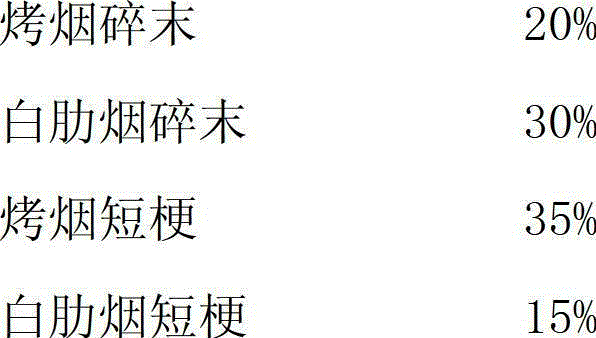

[0040] Embodiment 1 Preparation of reconstituted tobacco leaves for hybrid cigarettes

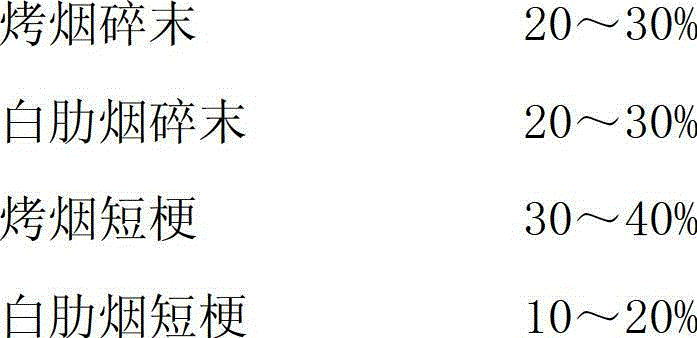

[0041] 1) Mix flue-cured tobacco powder, Burley tobacco powder, flue-cured tobacco short stem, and Burley tobacco short stem according to the mass percentages in Table 1 to obtain a mixed raw material, and mix tobacco stems (flue-cured tobacco short stem and Burley tobacco Tobacco short stems) are pre-soaked in water at 50-60°C, and separated from solid and liquid after pre-soaking for 30 minutes to obtain tobacco stem pre-extraction liquid and pre-soaked tobacco stems.

[0042] Table 1 Mixed reconstituted tobacco raw material formula:

[0043]

[0044]

[0045] 2) Mix the pre-soaked tobacco stems and tobacco leaf powder (flue-cured tobacco powder and burley tobacco powder) evenly, then soak, beat, and separate solid and liquid to obtain a mixed extract and solid.

[0046] 3) Combine the tobacco stem pre-extraction solution and the mixed extraction solution to obtain soluble matter, ...

Embodiment 2

[0050] 1. Experimental method

[0051] The mixed reconstituted tobacco leaf prepared in Example 1 was shredded to obtain reconstituted tobacco.

[0052] During the preparation of Zhongnanhai (gold 8mg) cigarettes, the mixed reconstituted tobacco prepared in Example 1 was used to replace 8% of the shredded tobacco.

[0053] The specific method is: in Zhongnanhai (gold 8mg) cigarettes, 8% of the shredded tobacco in the shredded tobacco is replaced with shredded tobacco of mixed reconstituted tobacco leaves prepared by the method in Example 1 of the present invention. Cigarettes containing shredded tobacco cut from reconstituted tobacco leaves in Example 1 and Zhongnanhai (gold 8mg) cigarettes prepared by the original method have different degrees of reduction in smoke index and harmful components. The specific application conditions are shown in Table 4, Table 5, and Table 6 below. .

[0054] 2. Experimental results

[0055] Table 4: Comparison of physical and chemical indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com