Sintered neodymium-iron-boron permanent magnet material and preparation method thereof

A permanent magnet material, neodymium iron boron technology, applied in the direction of magnetic materials, inductors/transformers/magnet manufacturing, magnetic objects, etc., can solve the problem of magnet performance continuity without making attempts, without targeted technical reserves, and unfavorable magnets Overall performance and other issues, to achieve the effect of enhancing bonding, improving overall resistance, and promoting mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

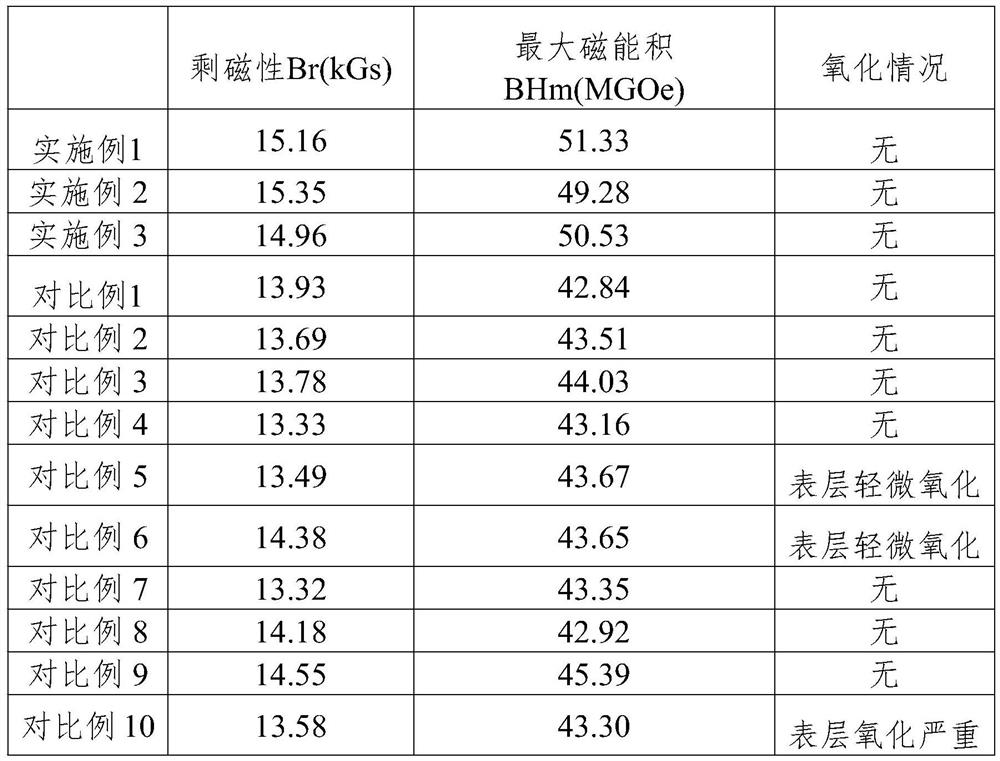

Embodiment 1

[0024] A sintered NdFeB permanent magnet material, made of the following raw materials in parts by mass: 5 parts of zinc-neodymium alloy, 8 parts of praseodymium-iron alloy, 0.3 part of molybdenum disilicide, 0.1 part of silicon hexaboride, 0.01 part of aluminum-rhenium alloy, 0.2 parts of silicon alloy, 1 part of manganese-nickel alloy, 1 part of boron-magnesium alloy, 50 parts of iron powder, and 5 parts of protective film alloy; the mass percentage of neodymium in the zinc-neodymium alloy is 15%, and the balance is zinc; the praseodymium-iron alloy The mass percentage of praseodymium is 1%, and the balance is iron; the mass percentage of rhenium in the aluminum-rhenium alloy is 1%, and the balance is aluminum; the mass percentage of silicon in the aluminum-silicon alloy is 8%, and the balance is aluminum; The mass percentage of nickel in the manganese-nickel alloy is 0.8%, and the balance is manganese; the mass percentage of boron in the boron-magnesium alloy is 5%, and the ...

Embodiment 2

[0032] A sintered NdFeB permanent magnet material, made of the following raw materials in parts by mass: 10 parts of zinc-neodymium alloy, 10 parts of praseodymium-iron alloy, 0.8 part of molybdenum disilicide, 0.5 part of silicon hexaboride, 0.1 part of aluminum-rhenium alloy, 0.9 parts of silicon alloy, 3 parts of manganese-nickel alloy, 5 parts of boron-magnesium alloy, 65 parts of iron powder, and 7 parts of protective film alloy; the mass percentage of neodymium in the zinc-neodymium alloy is 18%, and the balance is zinc; the praseodymium The mass percentage of praseodymium in the iron alloy is 3%, and the balance is iron; the mass percentage of rhenium in the aluminum-rhenium alloy is 4%, and the balance is aluminum; the mass percentage of silicon in the aluminum-silicon alloy is 12%, and the balance is Aluminum; the mass percent of nickel in the manganese-nickel alloy is 3%, and the balance is manganese; the mass percent of boron in the boron-magnesium alloy is 10%, and ...

Embodiment 3

[0040] A sintered NdFeB permanent magnet material, made of the following raw materials in parts by mass: 7 parts of zinc-neodymium alloy, 9 parts of praseodymium-iron alloy, 0.5 part of molybdenum disilicide, 0.2 part of silicon hexaboride, 0.054 part of aluminum-rhenium alloy, 0.43 parts of silicon alloy, 2 parts of manganese-nickel alloy, 3 parts of boron-magnesium alloy, 57 parts of iron powder, and 6 parts of protective film alloy; the mass percentage of neodymium in the zinc-neodymium alloy is 16%, and the balance is zinc; the praseodymium The mass percentage of praseodymium in the iron alloy is 2%, and the balance is iron; the mass percentage of rhenium in the aluminum-rhenium alloy is 2%, and the balance is aluminum; the mass percentage of silicon in the aluminum-silicon alloy is 12%, and the balance is Aluminum; the mass percentage of nickel in the manganese-nickel alloy is 0.8%, and the balance is manganese; the mass percentage of boron in the boron-magnesium alloy is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com