Formula and production process of tire with new outer contour

A technology for outer contours and tires, which is applied to special tires, tire parts, tires, etc., can solve problems such as high tire failure rate, tire rolling heat, and insufficient tire service life, so as to improve tire performance and reduce rolling production. heat, prolonging the life of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is illustrated below with specific examples, but not limitation of the present invention.

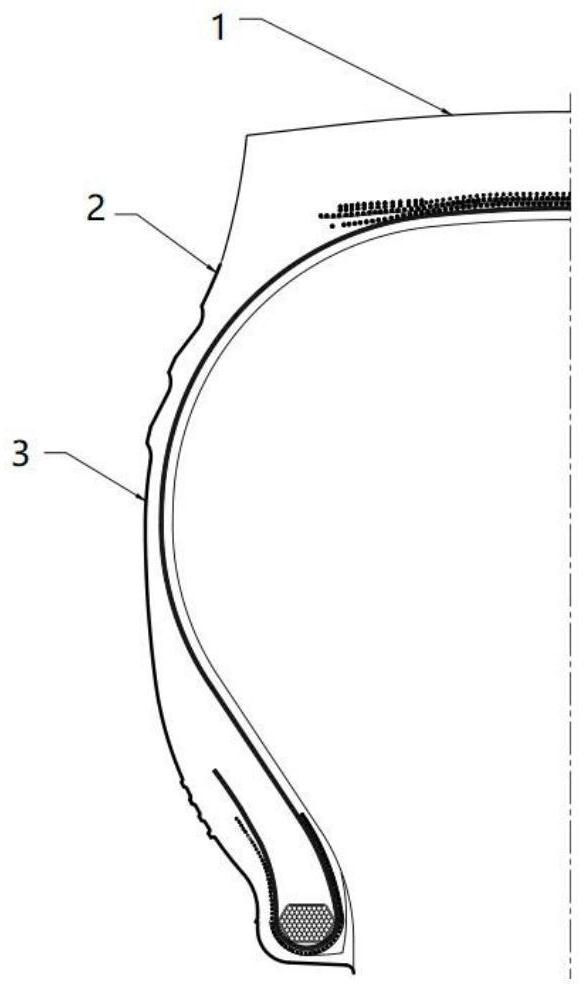

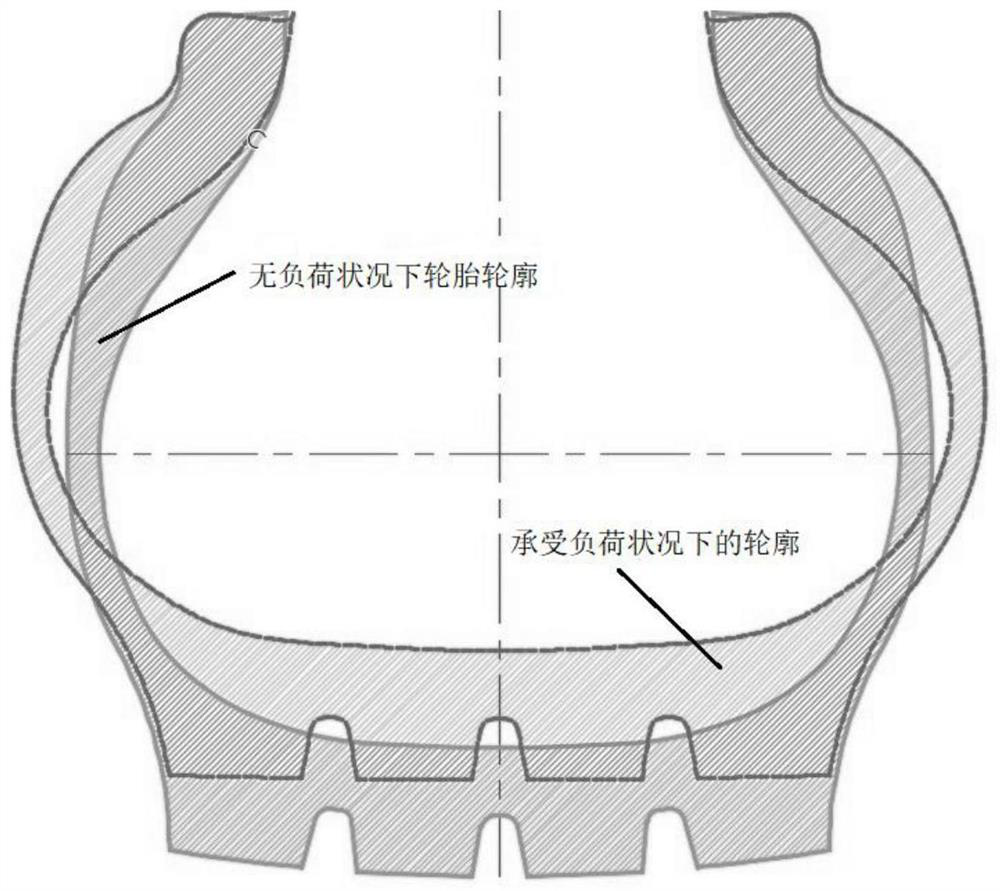

[0017] A new profile tire formula and its preparation process, including tread 1, tire shoulder 2 and sidewall 3, using finite element budget components and component tension distribution, without changing the material of the tire components, adjust the tread 1, tire The curvature of the shoulder 2 and the sidewall 3 is based on the prestress theory, and the contour model is designed to make the tire tread flat after inflation, and the ground contact pressure of each part is evenly distributed.

[0018] Made of the following raw materials by weight: 70-100 parts of natural rubber, 0-30 parts of synthetic rubber, 3.0-5.0 parts of active zinc oxide, 1.5-3 parts of stearic acid, 50-60 parts of carbon black, 3- 5 parts, 1.5-3.0 parts of silane coupling agent, 1.2-2.0 parts of accelerator, 0.8-1.8 parts of sulfur, 0.1-0.3 parts of anti-scorch agent.

[0019] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com