Ferrite magnetic material and ferrite sintered magnet

A technology of ferrite magnets and magnetic materials, applied in the fields of inorganic material magnetism, chemical instruments and methods, inductance/transformer/magnet manufacturing, etc., can solve the problems of insufficient magnetic properties of magnets, unsatisfactory magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0062] Hereinafter, the present invention is explained in more detail by the following examples. However, the following examples are intended to further illustrate the invention without limiting its scope thereto.

Embodiment

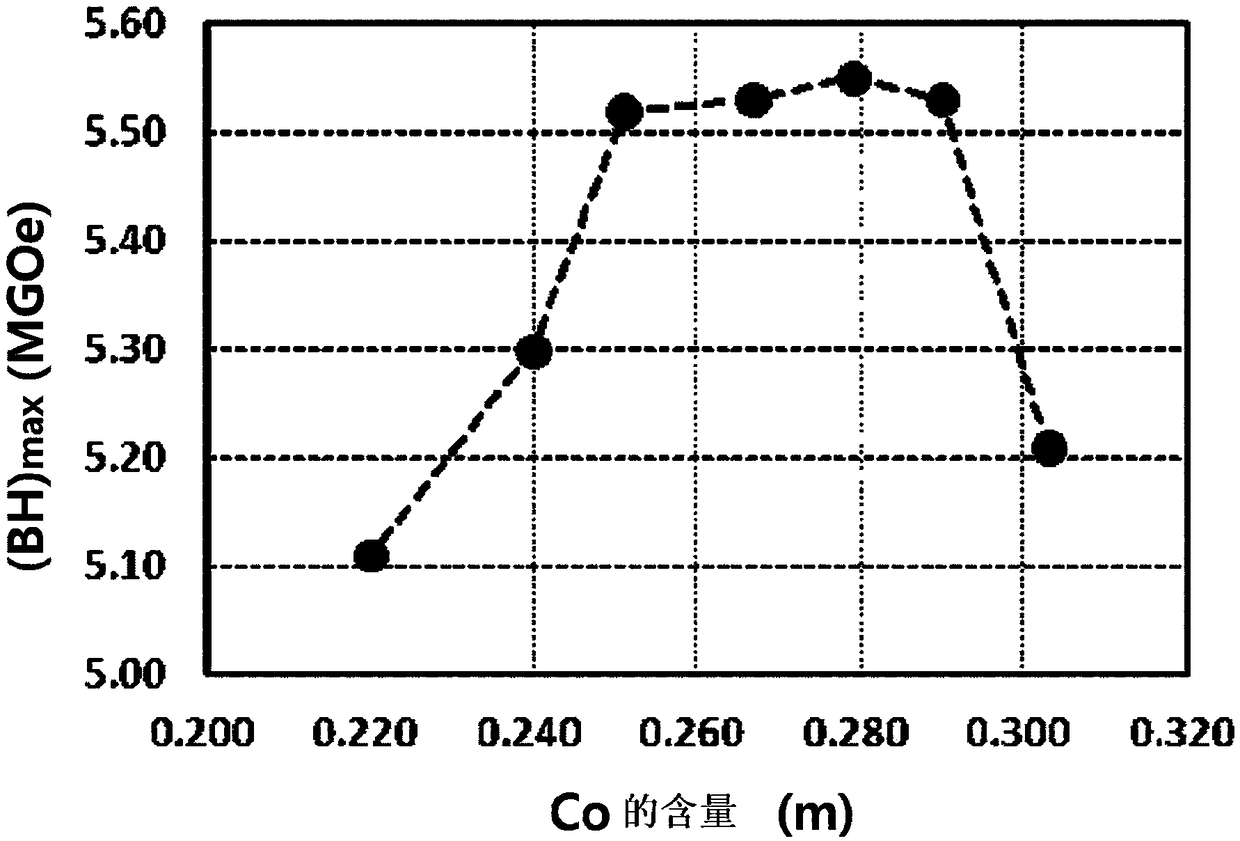

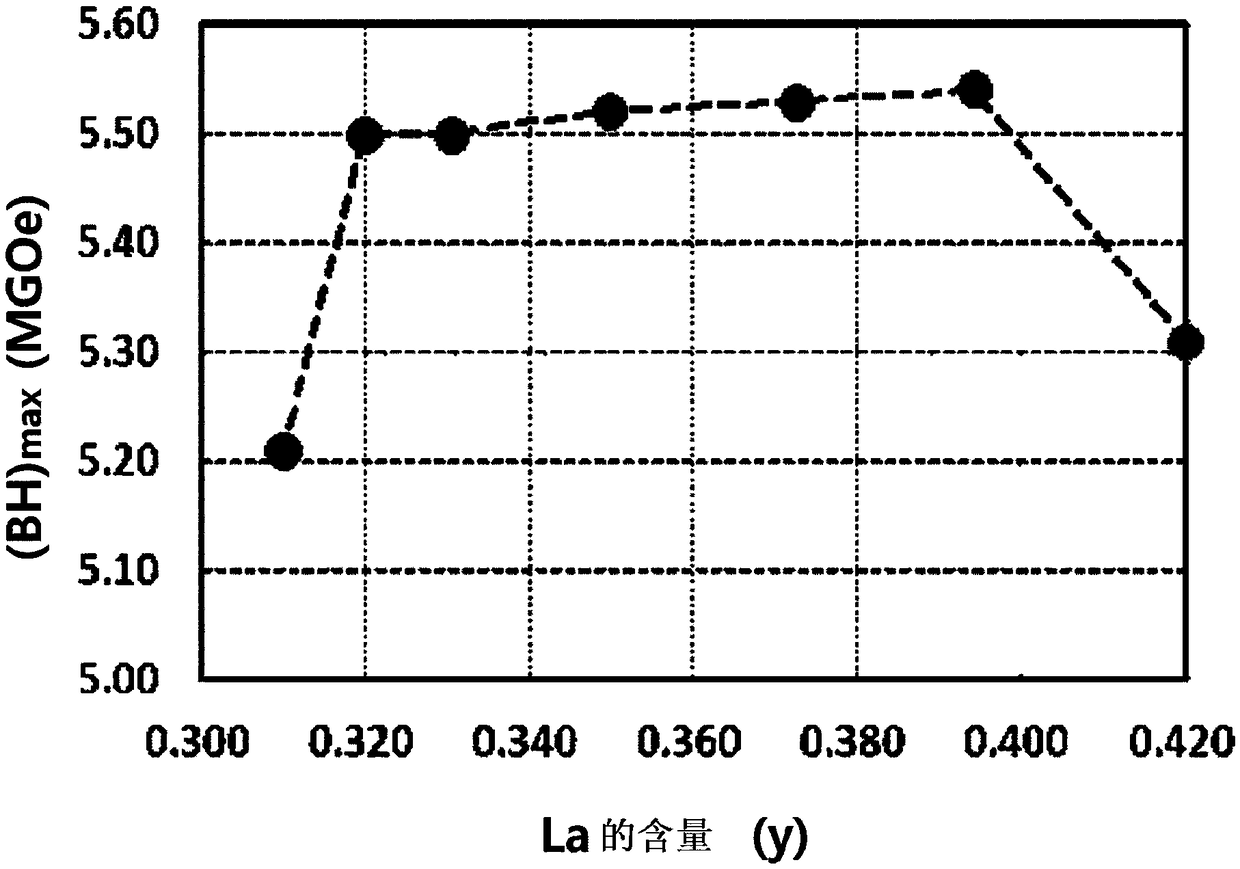

[0064] Reference example: Measurement of magnetic properties and density

[0065] The maximum magnetic energy product ((BH) max ). Furthermore, the sintered ferrite magnets were each cut into a width of 5 mm and a thickness of 5 mm, and then their saturation magnetization (4πIs) in the first quadrant of the 4πI-H curve was measured for planes perpendicular to and parallel to the orientation plane, respectively. and the anisotropic magnetic field (H A ). The density of ferrite magnets is measured by the Archimedes method.

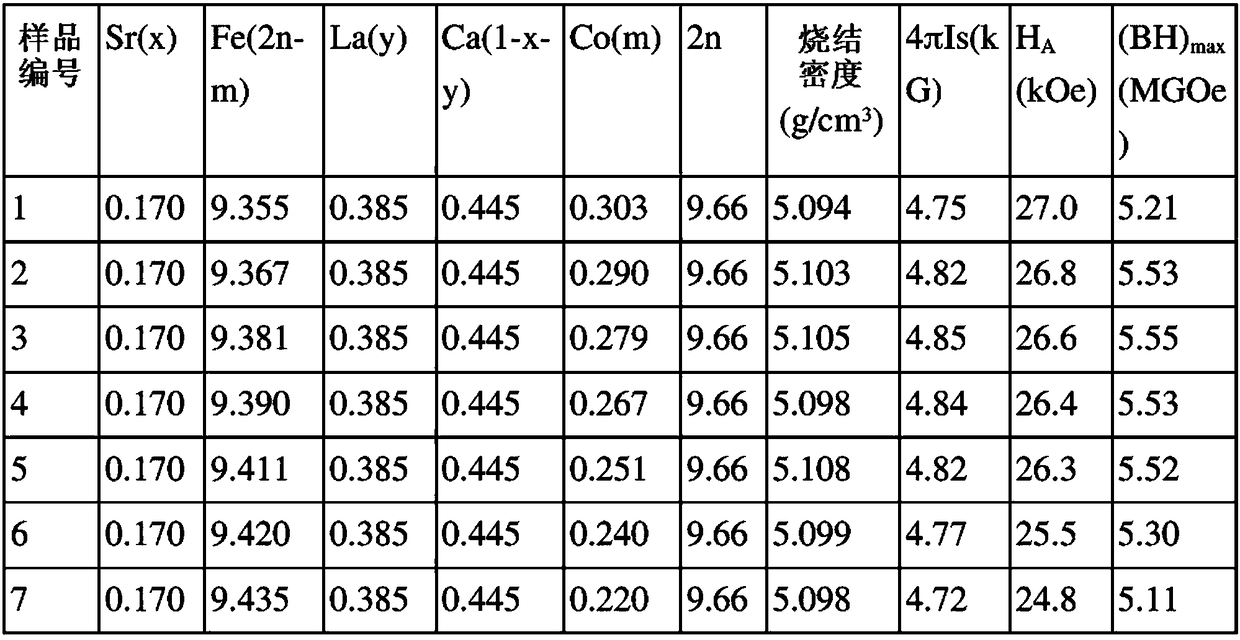

preparation example 1-1

[0067] Preparation Example 1-1: Mixing Process

[0068] Iron Oxides (Fe with a purity of 99% or greater 2 o 3 ), strontium carbonate (SrCO 3 ), calcium carbonate (CaCO 3 ), lanthanum oxide (La 2 o 3 ) and cobalt oxide (Co 3 o 4 ) were used as starting materials. Blending these starting materials to make Ca (1-x-y) Sr x La y Fe (2n-m) co m o 19 A ferrite magnet that satisfies the composition shown in Table 1 below. In order to promote the ferrite reaction, based on its total weight, 0.1 wt% H 3 BO 3 . The blend material was mixed with water to a concentration of 40% by weight, followed by wet cycle mixing for 2 hours. The raw material thus obtained was dried at 130° C. for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com