Brake disc material for forging high-speed train

A technology for high-speed trains and brake discs, applied in the direction of brake discs, etc., can solve the problems of not meeting the braking requirements of high-speed trains, accelerating the occurrence probability and expansion speed of thermal cracks, and unfavorable service life of brake discs. Achieve the effect of improving mechanical properties and corrosion resistance, high strength and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

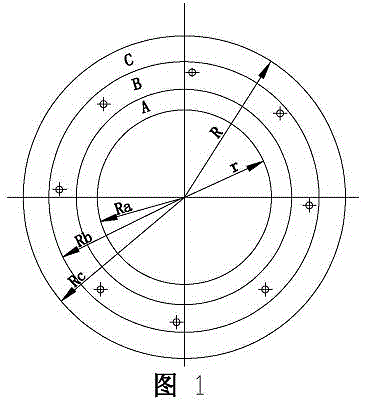

[0020] Such as figure 1 A high-speed train brake disc is shown. On the disc friction surface of the brake disc, there are mounting holes, the radius of the brake disc body is r, and the brake disc body is divided into three parts, A, B and C, which have the same material composition and different composition percentages. material area. The three material areas A, B, and C are three adjacent rings in sequence, and the brake disc body can be assembled from the three rings, or can be integrally forged from different component percentages in different areas. The same brake disc is divided into three material areas A, B, and C. The composition and mass percentage (Wt%) of the A material area are: C: 0.16, Si: 0.25, Mn: 0.80, Cr: 0.70 , W: 0.01, Ni: 0.80, Mo: 0.40, Cu: 0.05, SiC: 0.18, Al2O3: 0.20, V: 0.03, N: 0.0050, Re: 0.005, P≤0.015, S≤0.010, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com