Heat-crack-resistant medium-niobium cast TiAl alloy with over-peritectic solidification characteristic

A peritectic and anti-hot cracking technology, which is applied in the field of cast titanium-aluminum alloy, can solve problems such as cracking, achieve good performance, reduce hot cracking tendency, and less segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

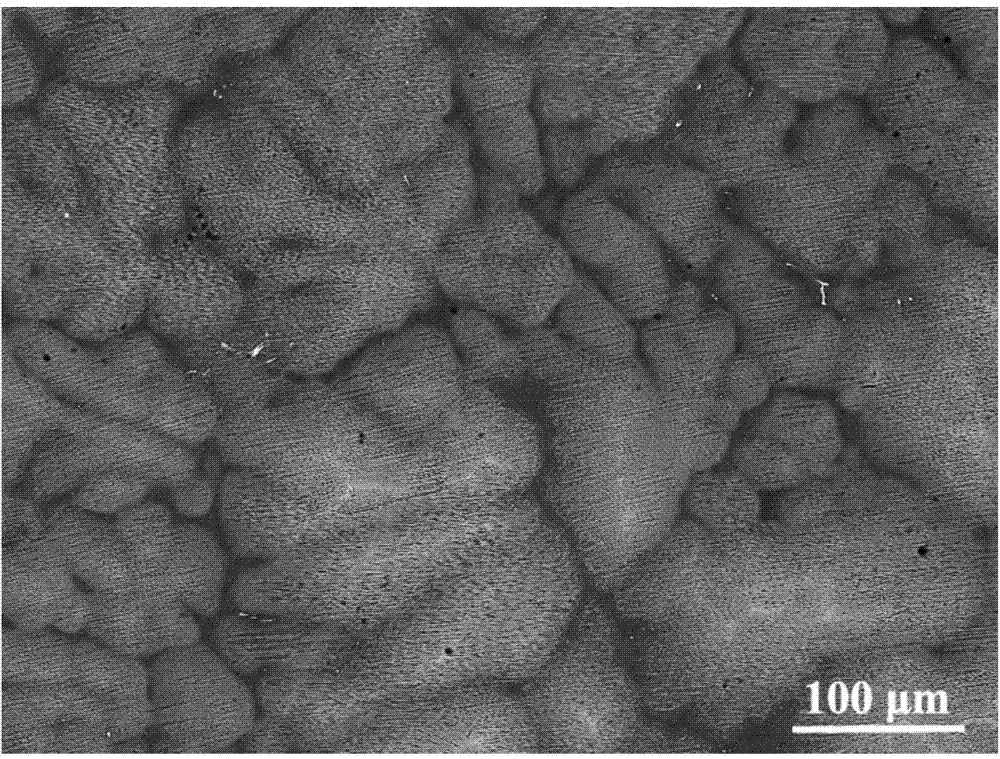

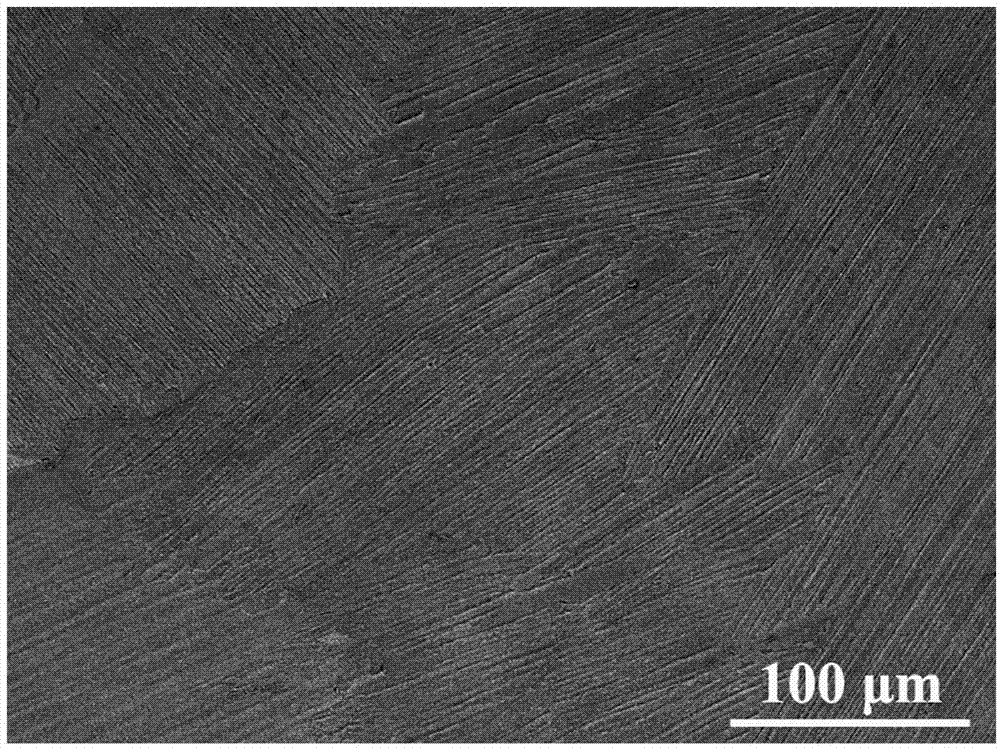

[0041] The invention is a hot-cracking-resistant medium niobium cast TiAl alloy with the feature of peritectic solidification, wherein the heat-cracking resistant medium niobium cast TiAl alloy with the feature of peritectic solidification is produced at an aluminum content of 48.29-48.4 at. It is obtained by adding 3-5 at.% niobium element to titanium-aluminum alloy. The niobium cast TiAl alloy in the heat cracking resistant type is composed of Al, Nb, Cr, B, N and Ti, wherein: Al is 48.29-48.4%, Nb is 3-5%; Cr is 1.9-2%; N 0.6-0.8%; B is 0.1-0.3%; the remainder is Ti. The stated percentages are atomic ratios.

[0042] In the hot-cracking-resistant medium niobium cast TiAl alloy with the characteristics of hyperperitectic solidification, the sum of the Al equivalents of Al and Cr elements and the aluminum equivalent of 3-5 at.% niobium elements should be in the over-clad phase of the TiAl alloy diagram. crystalline region.

[0043] The content of peritectic phase in the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com