Method for preparing high-speed steel composite roll for hot rolling

A technology for hot rolling rolls and composite rolling rolls is applied in the field of preparation of high-speed steel composite hot rolling rolls to achieve the effects of improving cold and thermal fatigue properties, uniform outer layer thickness and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

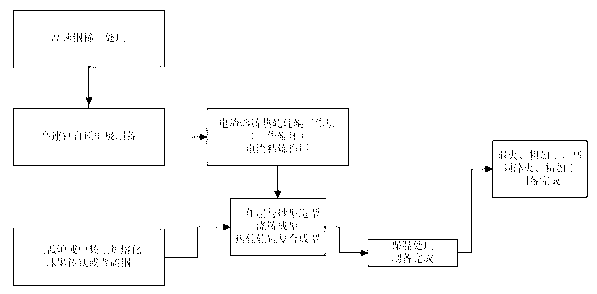

Problems solved by technology

Method used

Image

Examples

Embodiment 1

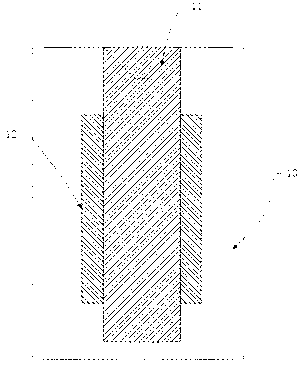

[0031] (1) Preparation of self-consumable electrodes in the working layer: According to the chemical composition requirements of high-speed steel, batching, smelting in an intermediate frequency furnace, adding 0.5% of rare earth modifier, and pouring to obtain high-speed steel consumable electrodes;

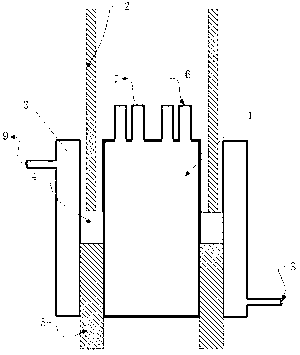

[0032] (2) Forming of the outer ring of the working layer: according to the electroslag remelting process, the slag material is heated to 250°C for 2 hours, then dehydrated and degassed, melted in the slag melting furnace, and the melted electroslag material is poured into the hollow pump In the ingot crystallizer, the high-speed steel consumable electrode is inserted into the slag pool for conventional electroslag refining, feeding, and ending. At the same time, the upper and lower ports of the crystallizer are protected with gas until the end of smelting, and the working ring of the high-speed steel hot-rolled roll is obtained. After the molding is completed, it is covered with...

Embodiment 2

[0041] (1) Preparation of consumable electrodes in the working layer: According to the chemical composition requirements of high-speed steel, ingredients are added, 0.3% of rare earth modifier is added, and consumable electrodes of high-speed steel are obtained by smelting in intermediate frequency furnace;

[0042] (2) Forming of the outer ring of the working layer: according to the electroslag remelting process, the slag material is heated to 250°C for 2 hours, dehydrated and degassed, melted in the slag melting furnace, and the melted electroslag material is poured into the hollow ingot In the crystallizer, the high-speed steel consumable electrode is inserted into the slag pool for conventional electroslag refining, feeding and finishing. At the same time, the upper and lower ports of the crystallizer are protected with gas until the end of smelting, and the working ring of the high-speed steel hot-rolled roll is obtained. After the molding is completed, it is covered with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com