Method for refining 3D printing aluminum alloy grains and improving thermal conductivity of 3D printing aluminum alloy grains

A 3D printing, aluminum alloy technology, applied in the direction of carbide, titanium carbide, metal processing equipment, etc., can solve the problem that 3D printing aluminum alloy is difficult to meet the requirements of grain refinement and thermal conductivity improvement at the same time, and 3D printing technology is not applicable , complex process and other issues, to achieve high actual thermal conductivity value, performance enhancement, and good wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

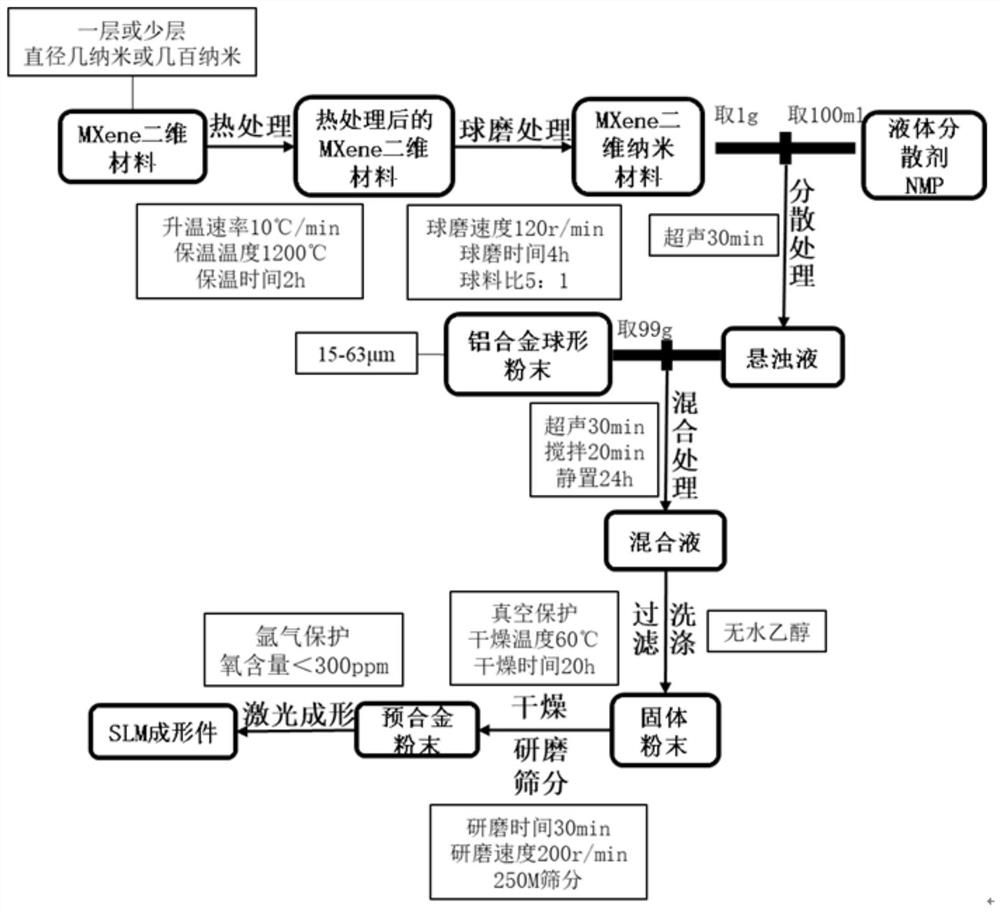

[0042] Such as figure 1 As shown, the specific steps of this embodiment are as follows:

[0043] (1) Select spherical aluminum alloy powder with a particle size in the range of 15-63 μm.

[0044] (2) Put Ti 2 The C-MXene two-dimensional nanosheet material was evenly spread in the crucible and placed in a vacuum tube furnace. After vacuuming, the temperature was raised to 1200 °C at a rate of 10 °C / min, then kept for 2 h, and then naturally cooled to room temperature.

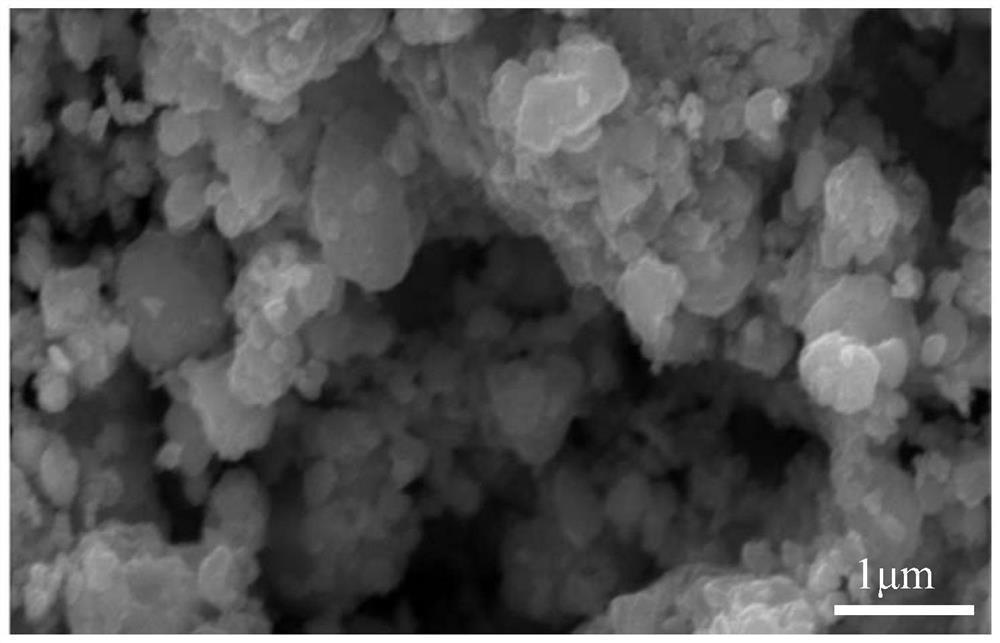

[0045] (3) Ti obtained by heat treatment 2 The C-MXene two-dimensional nanosheet material and ball milling medium were put into a vacuum ball mill tank under the protection of inert gas to seal and then ball milled. The ball milling speed was 120r / min, the ball milling time was 4h, and the mass ratio of the ball to material was 5:1. . Ti 2 C-MXene two-dimensional materials are ground into figure 2 Smaller volume discrete nanosheets are shown.

[0046] (4) Ti after ball milling 2 The C-MXene two-dimensiona...

Embodiment 2

[0050] The concrete steps of this embodiment are as follows:

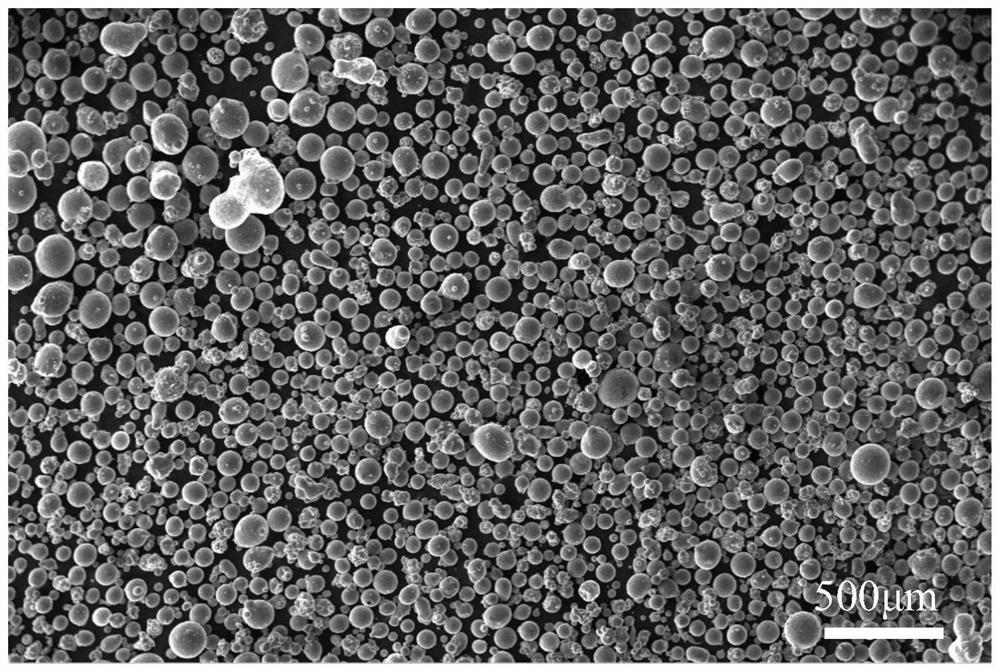

[0051] (1) Spherical 7075 aluminum alloy powder with a particle size in the range of 15-63 μm is selected, and its macroscopic appearance is as follows image 3 shown.

[0052] (2) Put Ti 3 C 2 - The MXene two-dimensional nanosheet material was evenly spread in the crucible and placed in a vacuum tube furnace. After vacuuming, the temperature was raised to 1200°C at a rate of 10°C / min, then kept for 2h, and then naturally cooled to room temperature.

[0053] (3) Ti obtained by heat treatment 3 C 2 -The MXene two-dimensional nanosheet material and ball milling medium were put into a vacuum ball mill tank under the protection of an inert gas to seal and then ball milled. The ball milling speed was 120r / min, the ball milling time was 4h, and the mass ratio of the ball to material was 5:1. Ti 3 C 2 -MXene two-dimensional nanosheet material is ground into smaller discrete nanosheets.

[0054] (4) Ti after ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com