Special hot-stamping die steel HS7 and preparation method thereof

A hot stamping die and die steel technology, applied in the fields of die materials, medium and high-grade hot stamping dies, and special hot stamping die steel, can solve the problems of high temperature wear resistance, hot crack performance, plastic deformation resistance and overall cracking resistance of hot stamping dies Insufficient hardness and wear resistance, high temperature strength, insufficient toughness and thermal fatigue resistance, insufficient optimization of alloy composition ratio, etc., to achieve the effect of good material isotropy, excellent thermal wear resistance, good quality effect and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

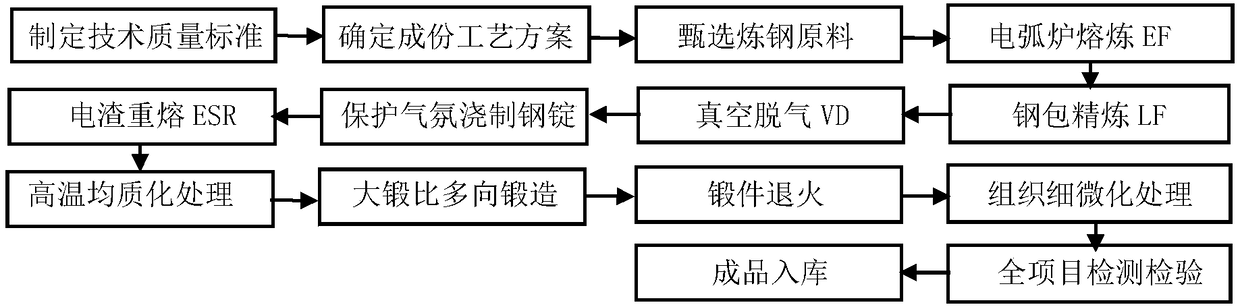

[0020] A kind of preparation method steps of novel special-purpose hot stamping die steel HS7 is as follows:

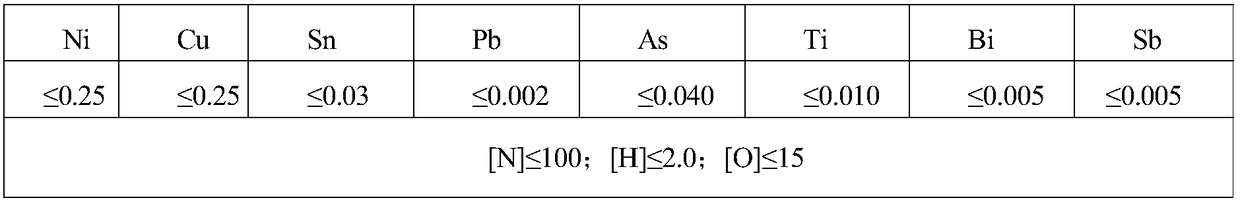

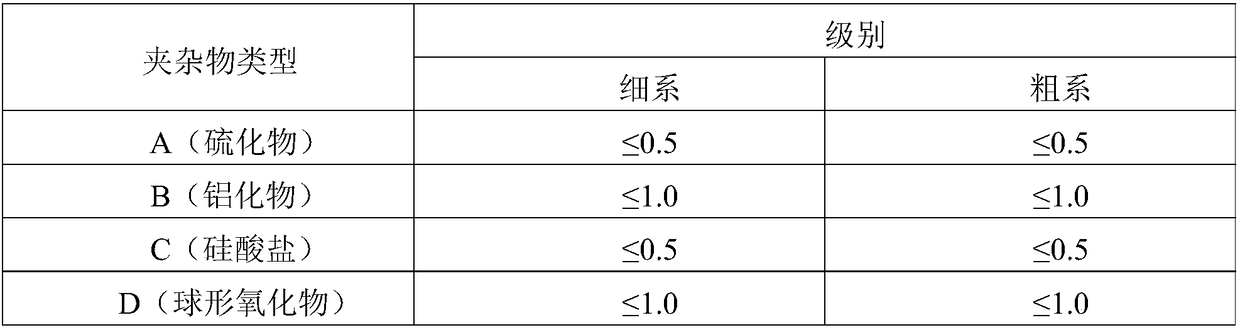

[0021] Step 1, carry out raw material batching according to the element composition weight percentage of die steel (C 0.41-0.45%; Si0.45-0.55%; Mn 0.35-0.45%; Cr 6.40-6.80%; Mo 1.20-1.40%; V 0.75-0.85% %; the rest is Fe). The selected raw materials are smelted in a high-grade electric arc furnace, the smelting temperature is 1510-1550°C, and the smelting time is 250-300 minutes. After sampling and testing the molten iron composition is basically up to standard, it is transferred to the LF furnace for ladle refining for 60-80 minutes. Make the necessary fine-tuning of the ingredients, and then carry out vacuum degassing in the VD vacuum degassing furnace for 30-40 minutes. After refining, the steel ingot is poured under the condition of protective gas, and after the steel ingot is cooled, it is annealed and stress-relieved at 800-840°C, thus completing the production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com