Die cast magnesium alloy with heat cracking resistance and high fluidity

A high-fluidity, thermal-crack-resistant technology, applied in the field of metal materials, can solve problems such as reduced fluidity, mold release of castings, reduced yield of air-tightness, poor shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

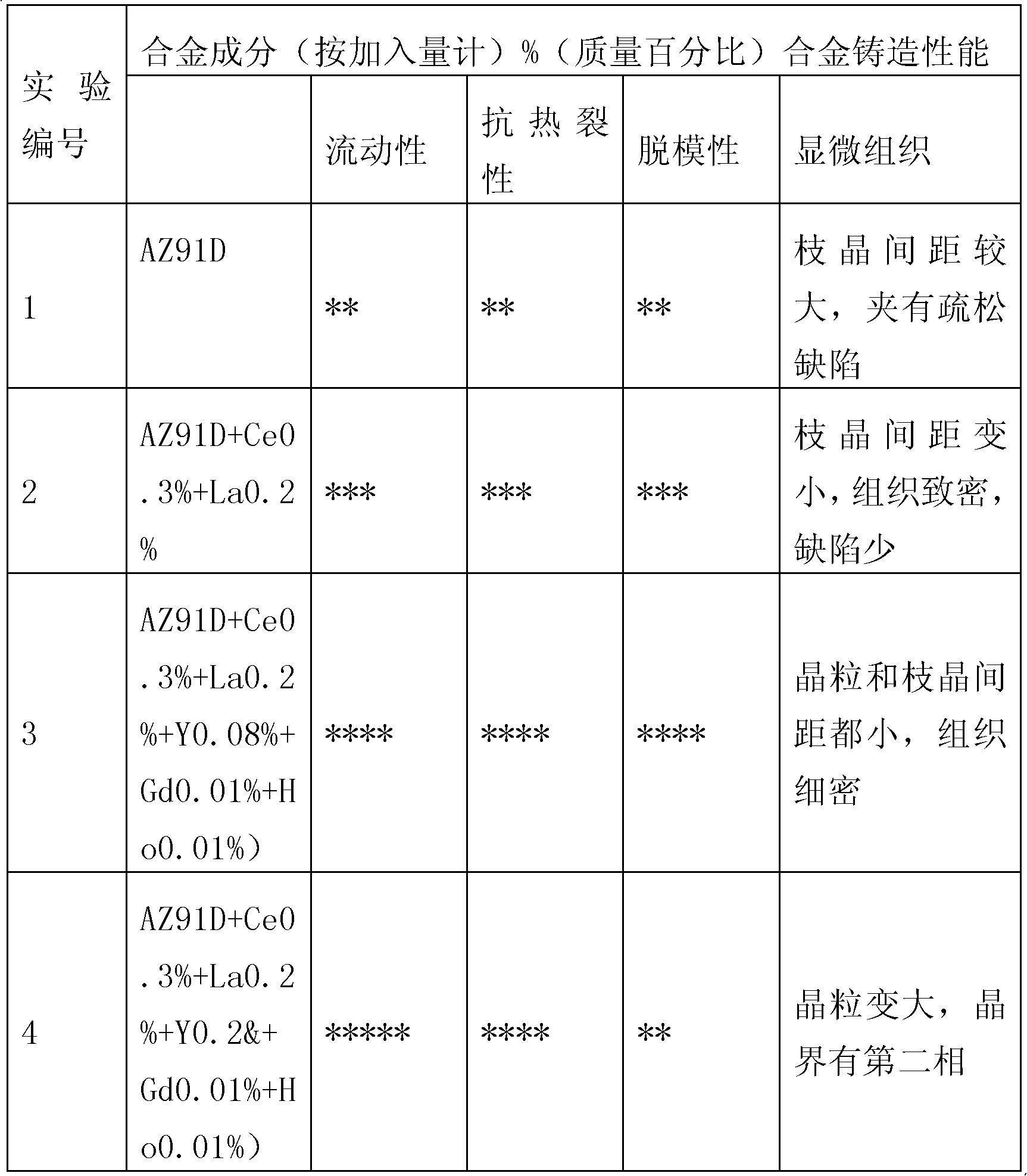

[0020] Embodiment 1 (test number 1):

[0021] Commercially available AZ91D alloy [currently the most commonly used commercial magnesium alloy, it is the name of the grade in ASTM in the United States, wherein A represents metal aluminum Al, Z represents metal zinc Zn, 9 represents that the content of aluminum is approximately 9%, 1 It means that the content of zinc is approximately 1%, and D refers to diecasting alloy, among which the brand name in the corresponding national standard in China is YZMgAl9Zn1(D)] 800 kg is put into a smelting iron crucible heated by gas, and the temperature is raised under the protection of argon Melting; Stir for 15 minutes at 700°C, remove the slag, and let stand for 30 minutes. Using a mold (the mold can simultaneously obtain a standard test rod and measure the length of the alloy flowing in the spiral tube), die-cast in a hot chamber die-casting machine at 640 ° C, and take 10 die-casting samples to evaluate the die-casting performance, appea...

Embodiment 2

[0022] Embodiment 2 (test number 2):

[0023] On the basis of Example 1, AZ91D is used to heat the alloy to 750°C and add Mg-Cet and Mg-La master alloys. The amount of Ce added accounts for 0.3% (mass percentage) of the total amount of the alloy, and the amount of La added accounts for the total amount of the alloy. The casting performance of 0.2% (mass percentage) is significantly improved (see Table 1), and the spiral flow length is increased by about 30% compared with AZ91D.

Embodiment 3

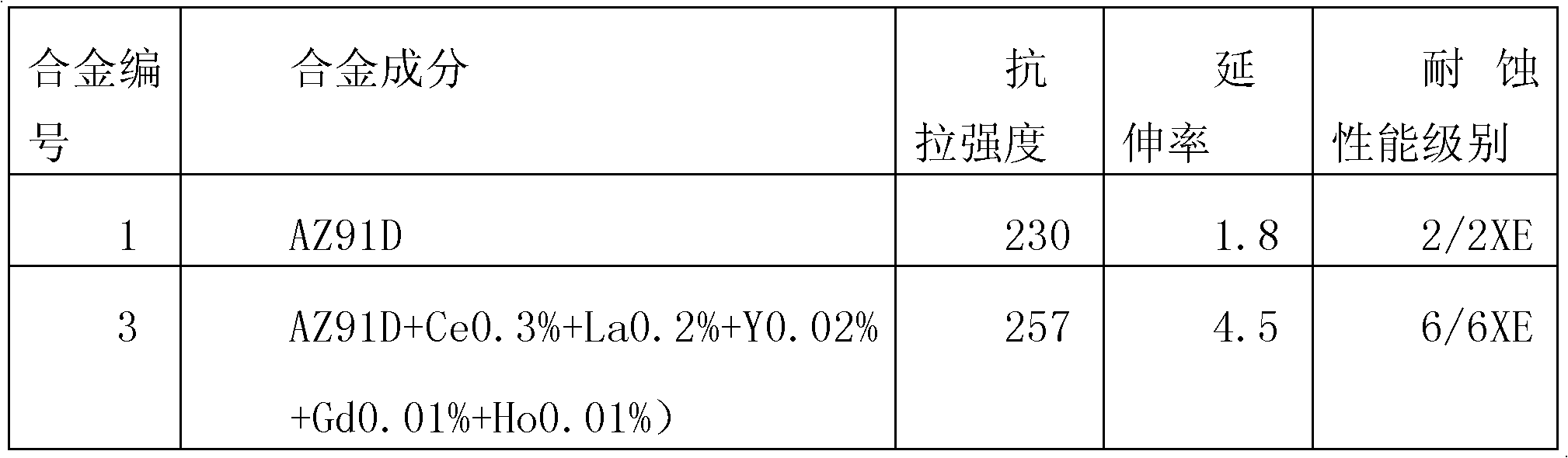

[0024] Embodiment 3 (test number 3):

[0025] The experimental conditions and process are basically the same as in Example 2, except that in addition to adding Ce0.3%, La0.2%, and adding Y0.08%, (Gd+Ho)0.02%, the casting performance has been greatly improved .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com