Impact-resistance double-roller roughing roll and manufacturing method thereof

A manufacturing method and rough roll technology, which is applied in the field of metallurgical rolls, can solve the problems of low heat resistance and impact resistance, and achieve high wear resistance and roll neck strength, excellent wear resistance, and good rolling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A kind of impact-resistant two-roller rough roll is used for raw material proportioning, high-quality steel scrap and alloying elements are selected, and the ingredients are formulated according to the following components and weight percentages:

[0016] C

Si

mn

Cr

Mo

V

Ni

P

S

0.56

0.82

0.55

4.29

0.6

0.29

0.83

0.015

0.013

[0017] The rest is Fe and unavoidable impurities.

[0018] In this embodiment, smelting in an electric arc furnace and a refining furnace reduces or eliminates harmful elements, improves the purity of molten steel, and provides a basis for high-performance requirements of rolls. After the roll is unpacked, it is directly subjected to preparatory heat treatment to prepare for the heat treatment of the finished product. Preliminary heat treatment includes two processes of normalizing and tempering. The normalizing temperature is 920°C and the temperin...

Embodiment 2~ Embodiment 6

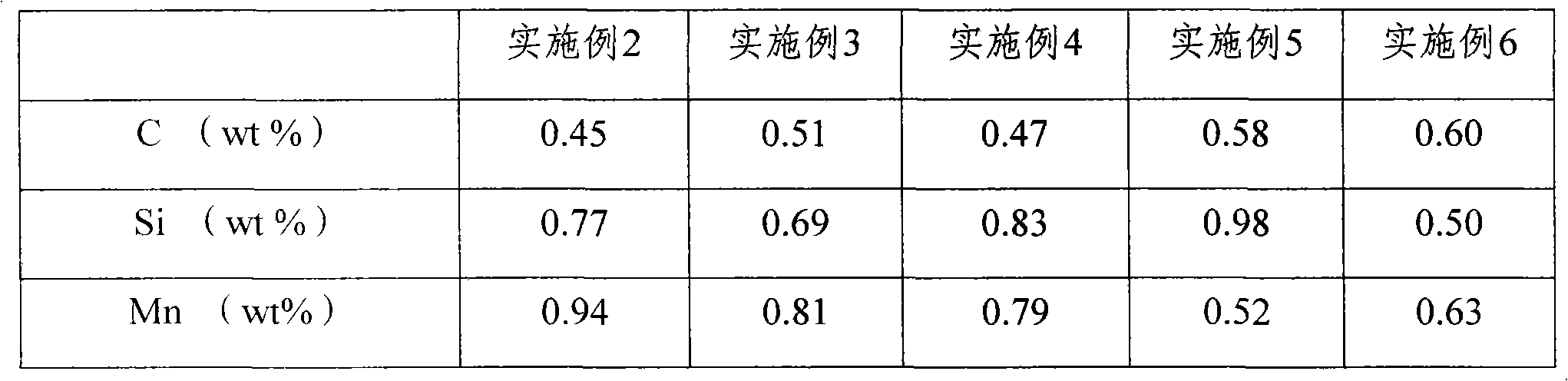

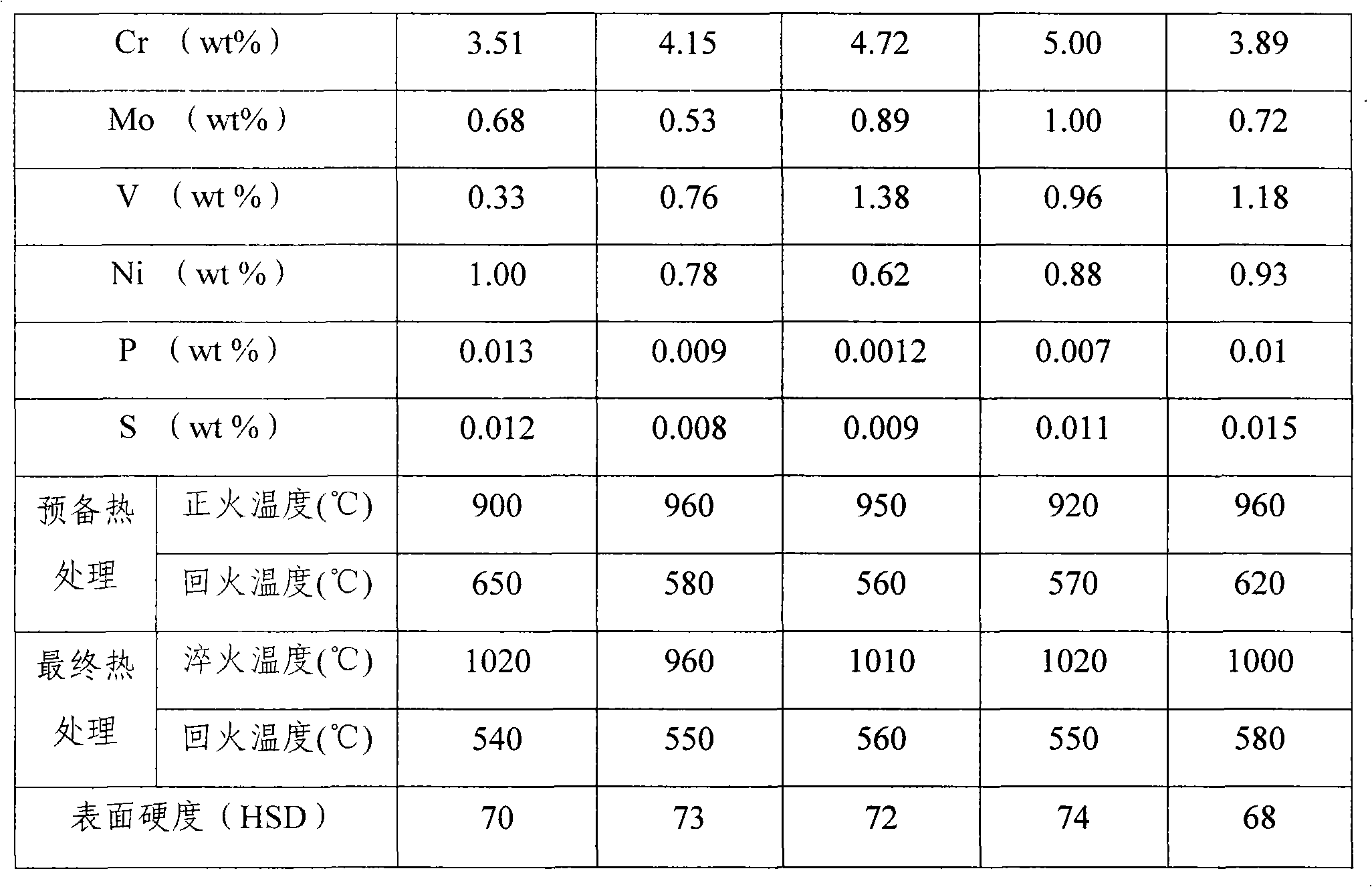

[0021] The manufacturing method of each embodiment is identical with embodiment 1, and the chemical composition and percentage composition and the surface hardness of finished product in process condition, roll material are shown in the table below:

[0022]

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com