Forging rough-rolling tool steel roller and manufacturing method thereof

A manufacturing method and tool steel technology, applied in the field of metallurgical rolls, can solve problems such as low strength, failure to meet rolling requirements, poor wear resistance, etc., and achieve the effect of improving thermal crack resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035]

[0036]

[0037] The rest of the above-mentioned composition components are Fe and unavoidable impurities.

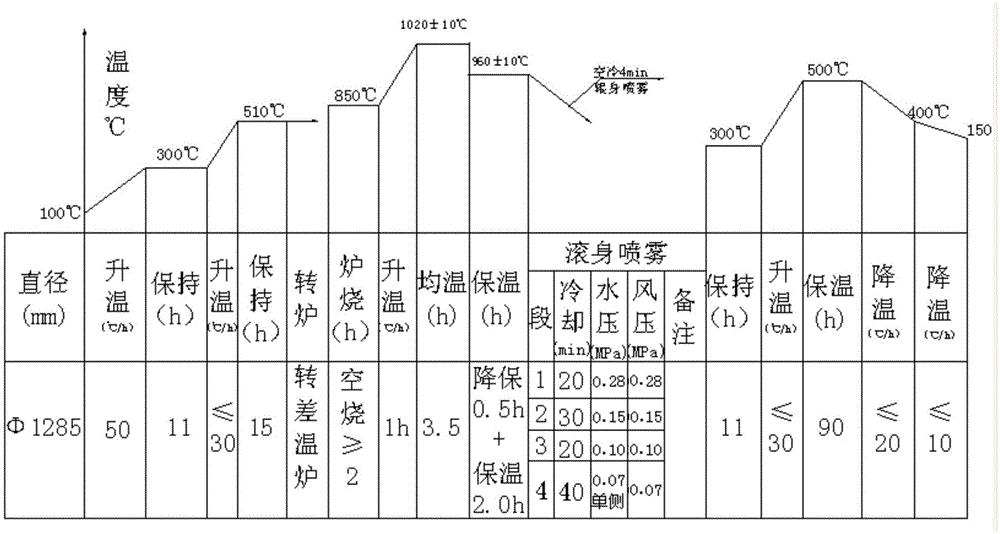

[0038] A method for manufacturing a forged rough-rolled tool steel roll, comprising the following steps:

[0039] 1) The tapping temperature of the electric arc furnace is controlled at 1600-1640°C, and then enters the LF refining furnace for smelting, adding lime 8-12kg / t, clay block 2-4kg / t, AD powder for slagging, and C+Si powder for reduction. In order to enhance the reduction effect, a small amount of Ca-Si powder can be used to maintain the reduction atmosphere. When the temperature of the refining furnace reaches 1700-1720°C (note that the temperature rises slowly to prevent the temperature drop during the VD process from being too large), VD treatment is performed, and the tapping temperature of the refining furnace is controlled at 1600-1600°C. 1650℃, cast into steel ingots, the pouring temperature is 1560~1565℃;

[0040] 2) Steel ingots are sent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com