Aluminum magnesium alloy and surface modifying method thereof

A technology of aluminum-magnesium alloy and surface modification, which is applied to the surface coating liquid device, metal material coating process, ion implantation plating, etc., which can solve the problem of high energy consumption, large pollution, immature technology and ineffective effect. Improve the corrosion resistance, improve the hydrophobic performance, and improve the effect of electromagnetic shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

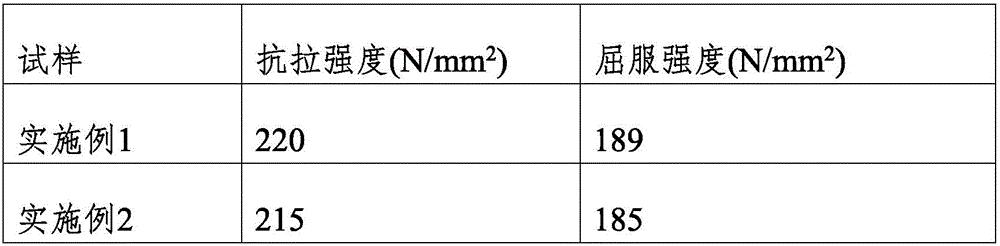

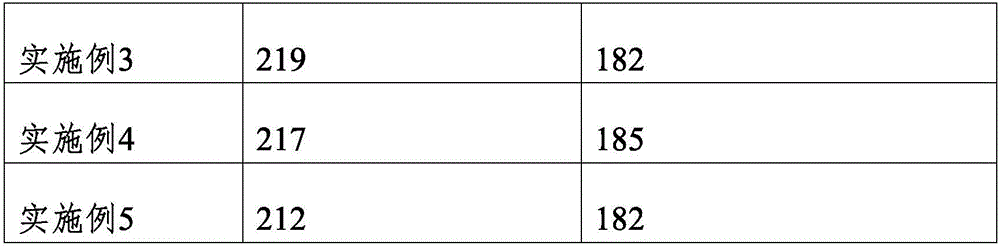

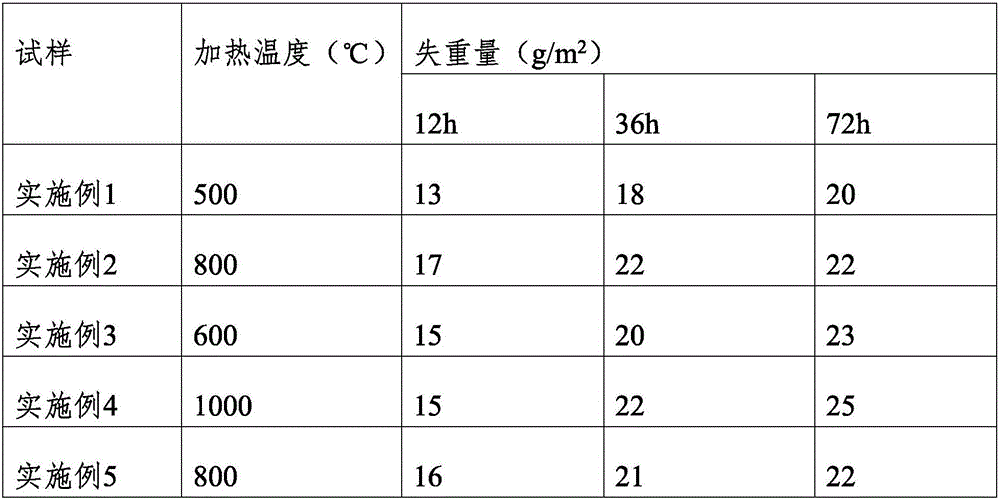

Examples

Embodiment 1

[0033] An aluminum-magnesium alloy is composed of the following raw materials in weight percentage: 0.01% of manganese, 0.12% of titanium, 0.3% of chromium, 6% of magnesium, 0.25% of iron, 0.07% of rare earth metal, and the balance is aluminum.

[0034] The rare earth metal is composed of the following components in mass ratio: Y:Ce:La:Sc=1:2:2:1.

[0035] Material preparation:

[0036] The silicon-based coating is composed of the following components in a mass ratio of ethyl orthosilicate:methyltrimethoxysilane:methyltriethoxysilane=3:1:5.

[0037] The preparation method of the silicon-based coating is as follows: add an ethanol solution with a quality of 1.5% orthosilicate into the orthosilicate and stir for 5 minutes, the volume concentration of the ethanol solution is 60%, and then add orthosilicate 13% tartaric acid, after stirring for 8 minutes, add methyltrimethoxysilane and methyltriethoxysilane in sequence, and heat at 68° C. for 1 hour to obtain a silicon-based coat...

Embodiment 2

[0046] An aluminum-magnesium alloy is composed of the following raw materials in weight percentage: 0.15% manganese, 0.2% titanium, 0.42% chromium, 8% magnesium, 0.1% iron, 0.1% rare earth metal, and the balance is aluminum.

[0047] The rare earth metal is composed of the following components in mass ratio: Y:Ce:La:Sc=2:1:3:1.

[0048] Material preparation:

[0049] The silicon-based coating is composed of the following components in a mass ratio of ethyl orthosilicate:methyltrimethoxysilane:methyltriethoxysilane=3:2:4.

[0050]The preparation method of the silicon-based coating is as follows: add an ethanol solution with a quality of 1.7% tetraethyl orthosilicate into the tetraethyl orthosilicate and stir for 4 minutes, the volume concentration of the ethanol solution is 70%, and then add the tetraethyl orthosilicate 10% tartaric acid, stirred for 10 minutes, then added methyltrimethoxysilane and methyltriethoxysilane in sequence, and heated at 65° C. for 1.5 hours to obtai...

Embodiment 3

[0059] An aluminum-magnesium alloy is composed of the following raw materials in weight percentage: 0.30% manganese, 0.15% titanium, 0.38% chromium, 7% magnesium, 0.2% iron, 0.12% rare earth metal, and the balance is aluminum.

[0060] The rare earth metal is composed of the following components in mass ratio: Y:Ce:La:Sc=1:1:5:1.

[0061] Material preparation:

[0062] The silicon-based coating is composed of the following components in a mass ratio of ethyl orthosilicate:methyltrimethoxysilane:methyltriethoxysilane=3:3:2.

[0063] The preparation method of the silicon-based coating is as follows: add an ethanol solution with a quality of 1.4 ethyl orthosilicate into the ethyl orthosilicate and stir for 2 minutes, the volume concentration of the ethanol solution is 55%, and then add the ethyl orthosilicate 11% tartaric acid, after stirring for 5 minutes, add methyltrimethoxysilane and methyltriethoxysilane in sequence, and heat at 60° C. for 2 hours to obtain a silicon-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com