High-temperature alloy and preparation method thereof

A technology for superalloy and parent alloy ingots, applied in the field of superalloys, can solve the problems of greatly different cross-sectional dimensions, complex supercharger turbine structure, easy hot cracking of blades, etc., to achieve good resistance to hot cracking and slow down the phenomenon of hot cracking , the effect of reducing the number and size of thermal crack formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

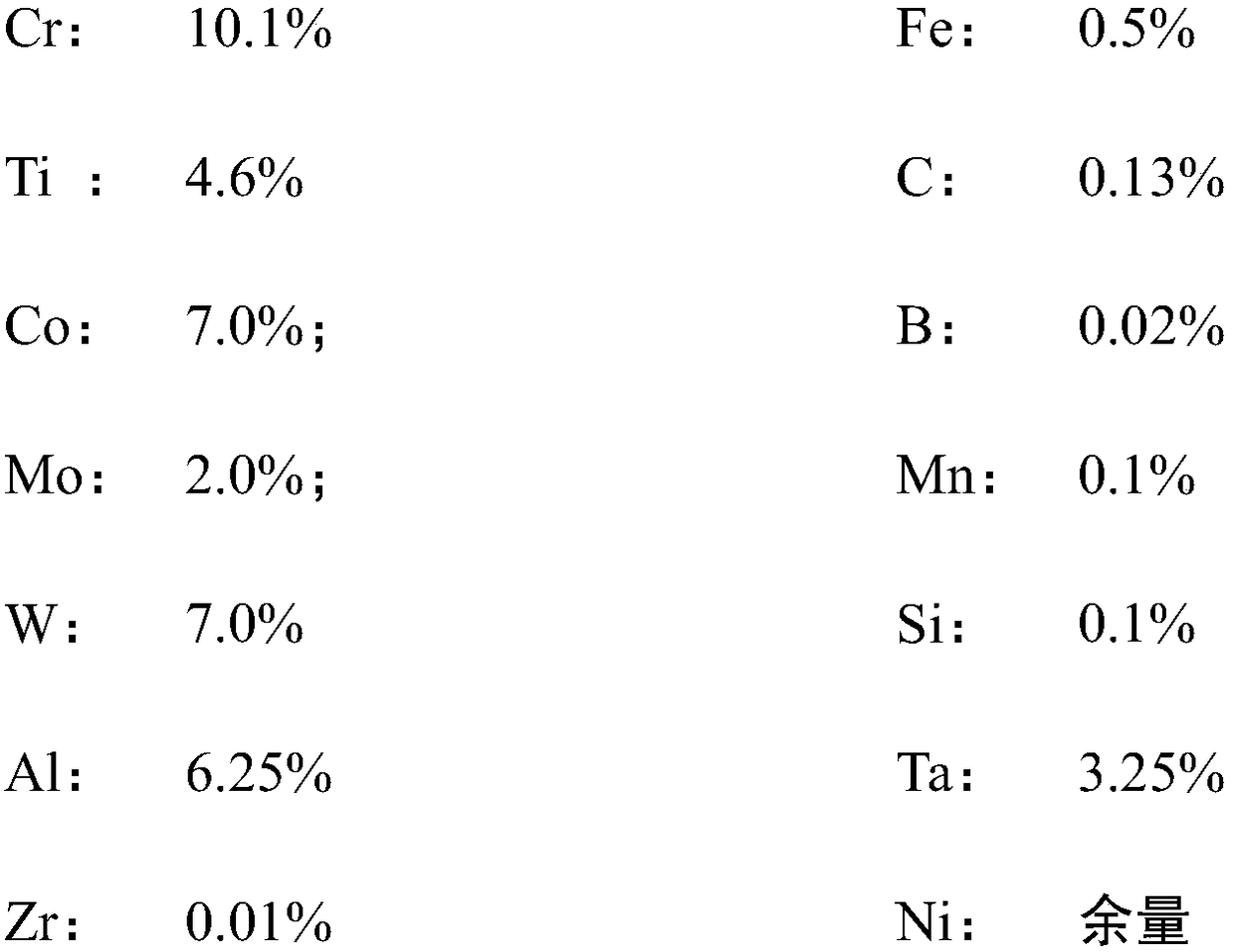

[0027] Such as figure 1 Shown, a kind of superalloy, according to the requirement of required hot cracking resistant superalloy, the superalloy of preparation comprises each component of following mass percent (wt.%):

[0028]

[0029] S1. Ingredients: weigh ingredients according to the above ratio;

[0030] S2. Master alloy smelting: put the Cr, Co, Mo, W, Zr, Fe, C, Mn, Si, Ta and Ni elements weighed in step 1 into the crucible for vacuum induction melting, and the added elements are completely dissolved Finally, turn on the magnetic stirring and continue the smelting time for 25 minutes; then stop heating for 5 seconds, then add Al, B and Ti elements to the melt and continue heating for 10 minutes. Then stop heating, let the liquid alloy cool with the furnace, and pour it into the ingot mold when the temperature of the alloy melt reaches 1600°C to form a master alloy ingot;

[0031] S3. Wax pattern mold preparation: Use the wax pattern mold of the casting to press out ...

Embodiment 2

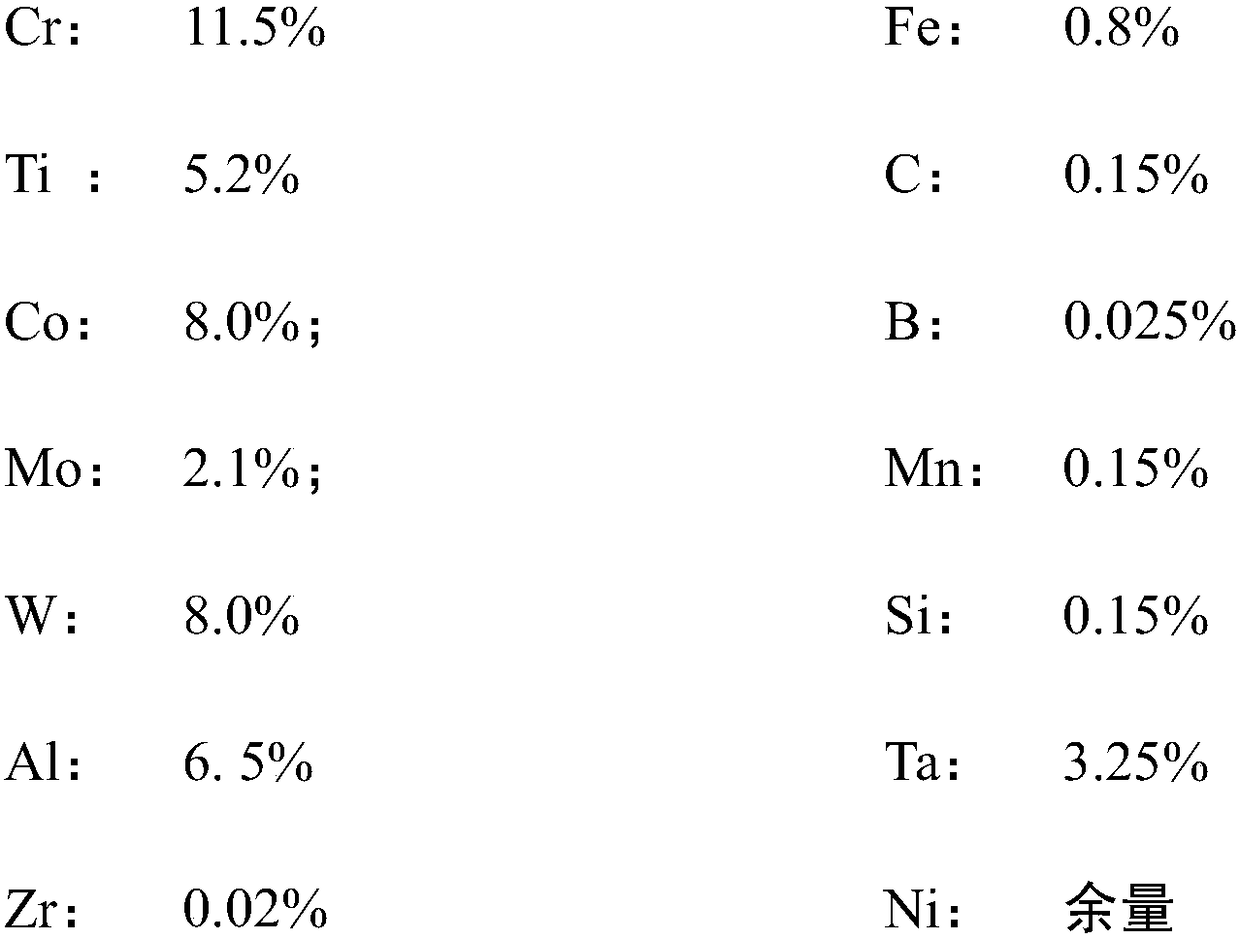

[0036] Such as figure 1 Shown, a kind of superalloy, according to the requirement of required hot cracking resistant superalloy, the superalloy of preparation comprises each component of following mass percent (wt.%):

[0037]

[0038] S1. Ingredients: weigh ingredients according to the above ratio;

[0039]S2. Master alloy smelting: put the Cr, Co, Mo, W, Zr, Fe, C, Mn, Si, Ta and Ni elements weighed in step 1 into the crucible for vacuum induction melting, and the added elements are completely dissolved Finally, turn on the magnetic stirring and continue the smelting time for 30 minutes; then stop heating for 15 seconds, then add Al, B and Ti elements to the melt and continue heating for 15 minutes. Then stop heating, let the liquid alloy cool with the furnace, and pour it into the ingot mold when the temperature of the alloy melt reaches 1650°C to form a master alloy ingot;

[0040] S3. Wax mold preparation: Use the wax mold of the casting to press out the required wax...

Embodiment 3

[0045] Such as figure 1 Shown, a kind of superalloy, according to the requirement of required hot cracking resistant superalloy, the superalloy of preparation comprises each component of following mass percent (wt.%):

[0046]

[0047]

[0048] S1. Ingredients: weigh ingredients according to the above ratio;

[0049] S2. Master alloy smelting: put the Cr, Co, Mo, W, Zr, Fe, C, Mn, Si, Ta and Ni elements weighed in step 1 into the crucible for vacuum induction melting, and the added elements are completely dissolved Finally, turn on the magnetic stirring and continue the smelting time for 39 minutes; then stop heating for 30 seconds, then add Al, B and Ti elements to the melt and continue heating for 20 minutes. Then stop heating, let the liquid alloy cool with the furnace, and pour it into the ingot mold when the temperature of the alloy melt reaches 1700°C to form a master alloy ingot;

[0050] S3. Wax pattern mold preparation: Use the wax pattern mold of the casting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com