Multi-channel reaction device for fast appraisement of hydrogen manufacturing performance of photocatalyst

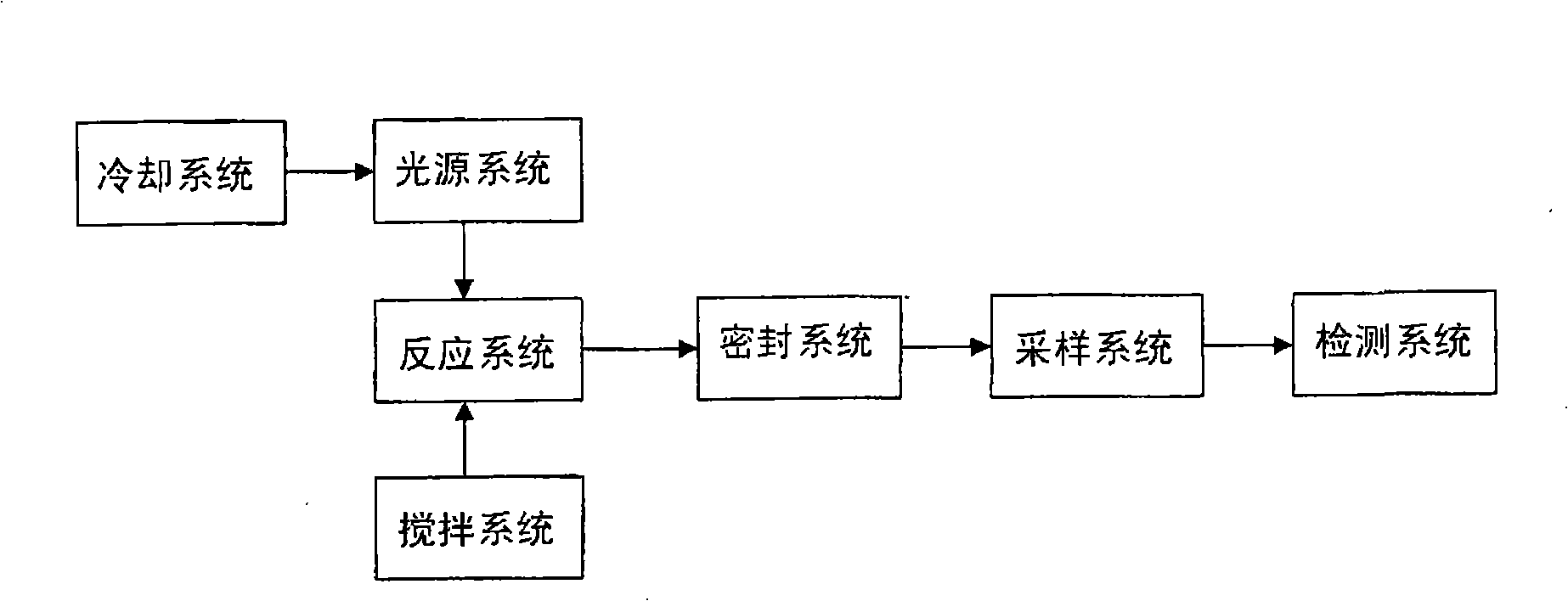

A reaction device, photocatalysis technology, applied in measuring devices, chemical method analysis, instruments, etc., can solve the problems of time-consuming activity evaluation, low reproducibility, error, etc., and achieve the effect of improving evaluation efficiency and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

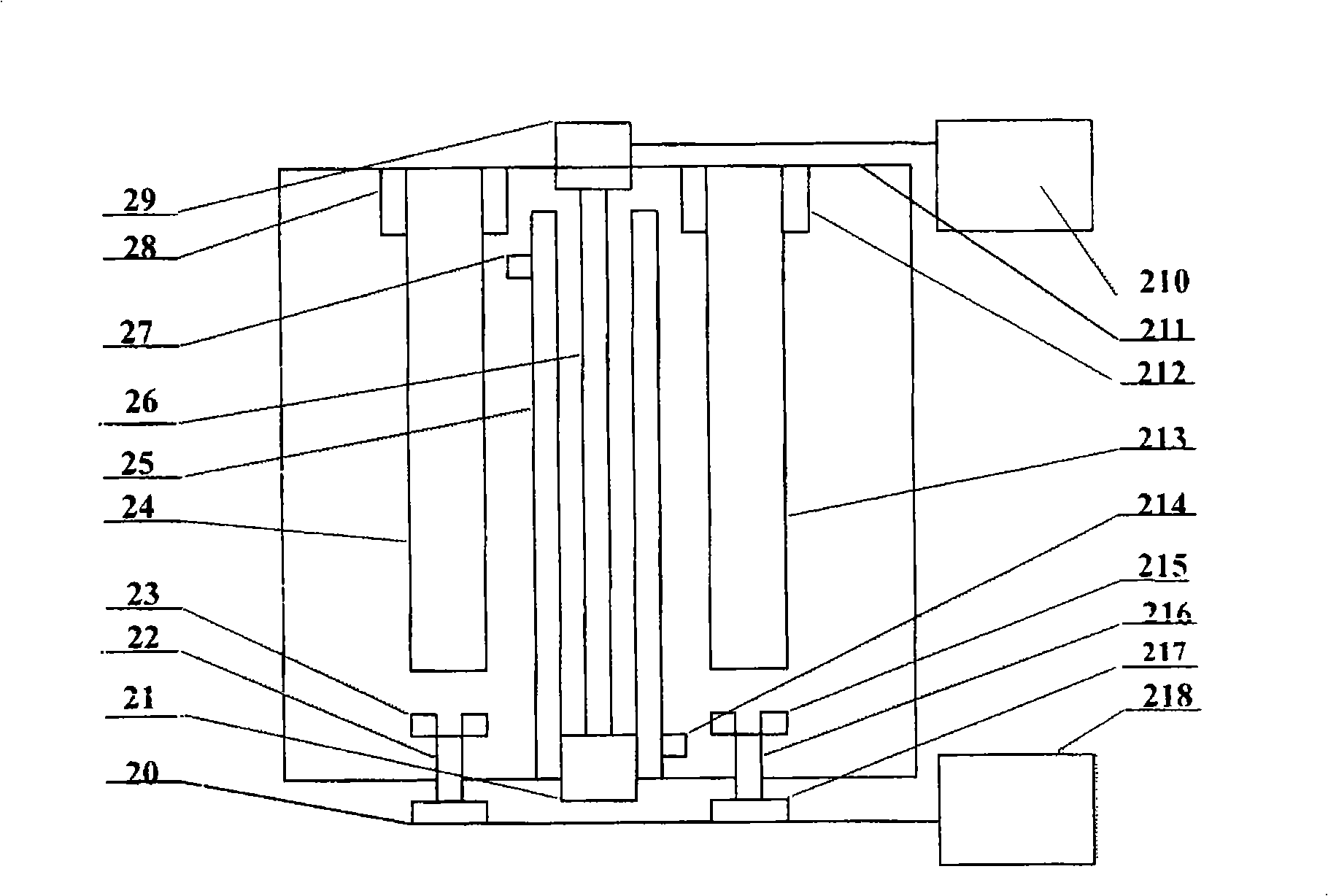

Method used

Image

Examples

specific Embodiment

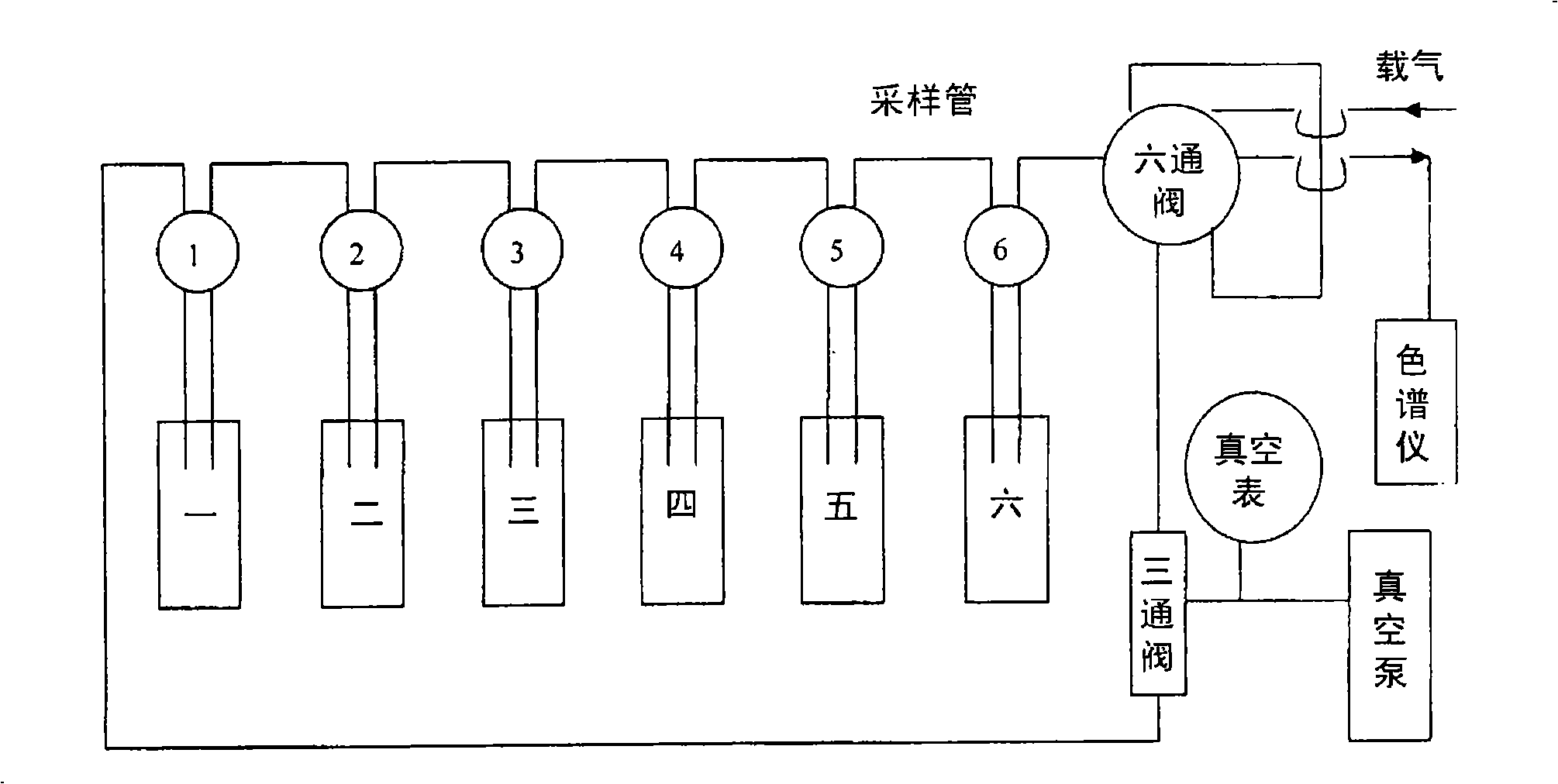

[0058] Vacuum the pipeline through the gas detection part first, put image 3 The three-way valves and four-way valves 1, 2, 3, 4, 5, and 6 shown are opened, and the pipeline is evacuated with a vacuum pump. After 15 minutes, the three-way valves and four-way valves 1, 2, 3, 4, 5 and 6 are closed, so that each quartz reaction tube is in a vacuum state. Then turn on the magnetic stirring motor and the tube-type light source motor, and control the stirring speed of the magnetic device to 1000r / min through the governor; adjust the speed of the tube-type light source motor to a constant 20r / min to control the rotation of the light source. Then the light source is energized, the cooling water is passed through the quartz cooling water jacket, and the reaction begins. After the reaction is over, turn on the vacuum pump, open the three-way valve, evacuate the sampling tube connected to the six-way valve, then close the three-way valve, open the four-way valve 1, and close the four-w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com