Measuring method for static balance of turbine vane wheel and device thereof

A measurement device and measurement method technology, applied in the field of precision measurement, can solve problems such as inability to eliminate, restrict measurement accuracy and accuracy, and achieve the effects of avoiding incomplete or excessive removal, improving measurement accuracy and sensitivity, and eliminating systematic errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

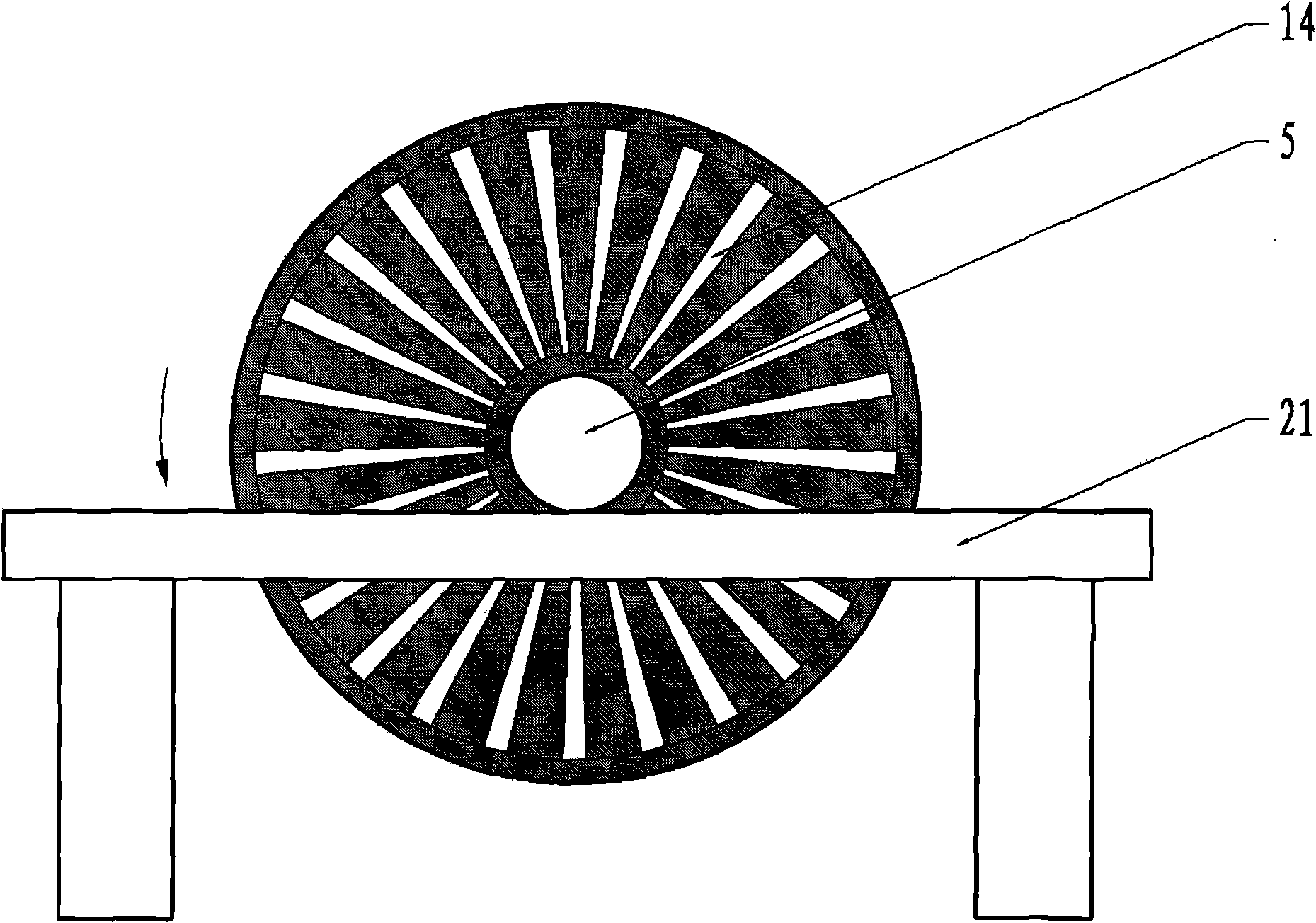

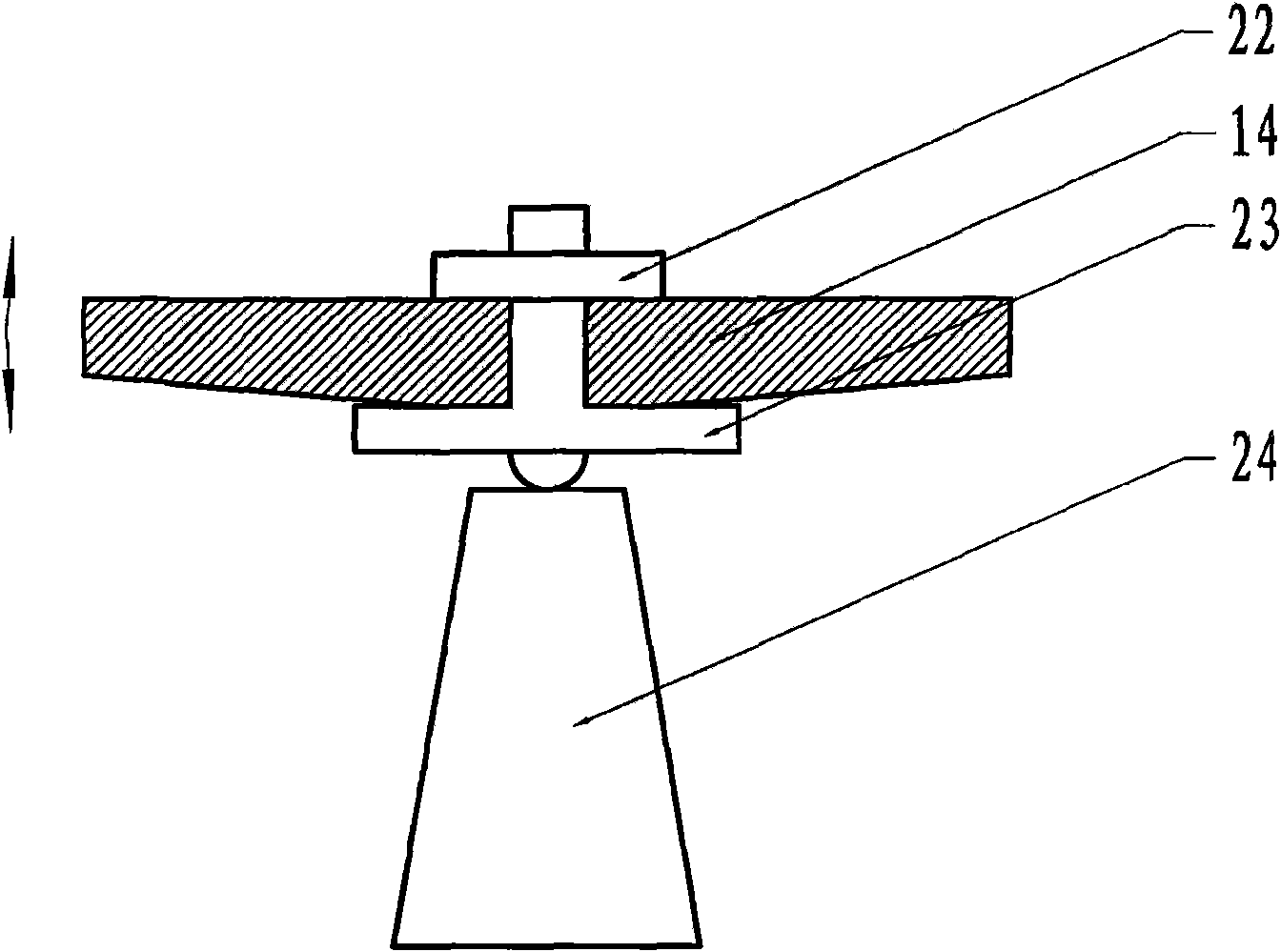

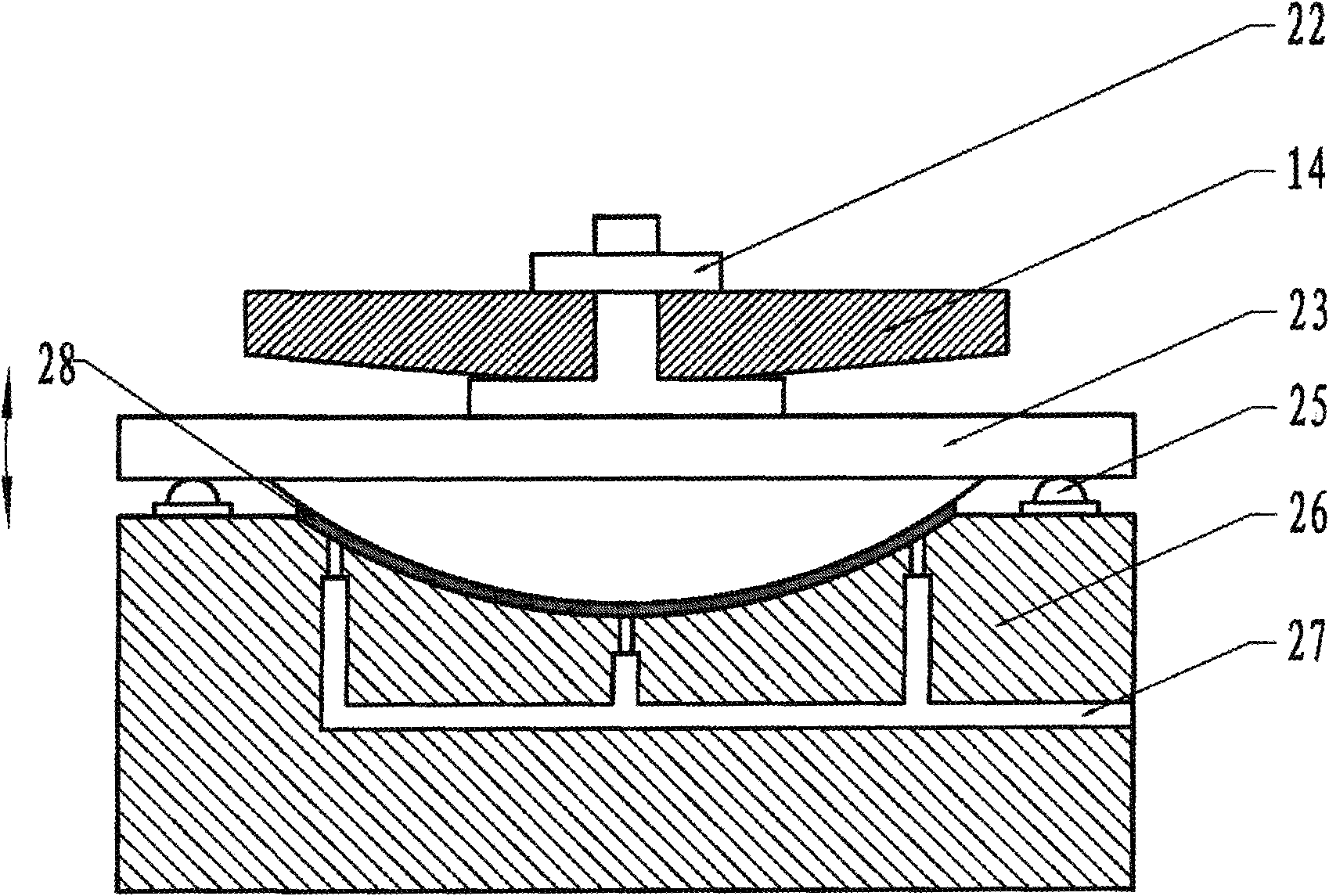

[0043] The structure of the embodiment of the present invention is as Figure 5 As shown, a steam turbine impeller static balance measurement device includes an impeller 14, a drive motor 1, a torque sensor 2, a data processing system 3, a bearing sleeve 4, a mandrel 5, a gas bearing support mechanism 7, a moving part 8, and a fixed part 10 , air bearing guide rail support mechanism 11, liquid bearing main shaft 13, liquid bearing support mechanism 16, rope 17, pulley frame 18, pulley 19 and weight 20; wherein; bearing sleeve 4 and mandrel 5 form gas bearing 6, moving part 8 It forms the air bearing guide rail 9 with the fixed part 10, the main shaft 13 and the impeller 14 form the liquid bearing 12, the driving motor 1 is connected with the torque sensor 2, and the bearing sleeve 4 is driven to rotate through the torque sensor 2, the center line of the bearing sleeve 4 and the impeller 14, etc. High and parallel, the two are in direct contact, and the bearing sleeve 4 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com