Rotational clap suction/pressure device

a technology of suction device and clap, which is applied in the direction of machines/engines, rotary/oscillating piston pump components, liquid fuel engines, etc., can solve the problems of very restrictive use of rotary engines of wankel sports cars, improve and improve the coupling strength of crank arms. , the effect of improving the mechanical strength of rotational pistons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

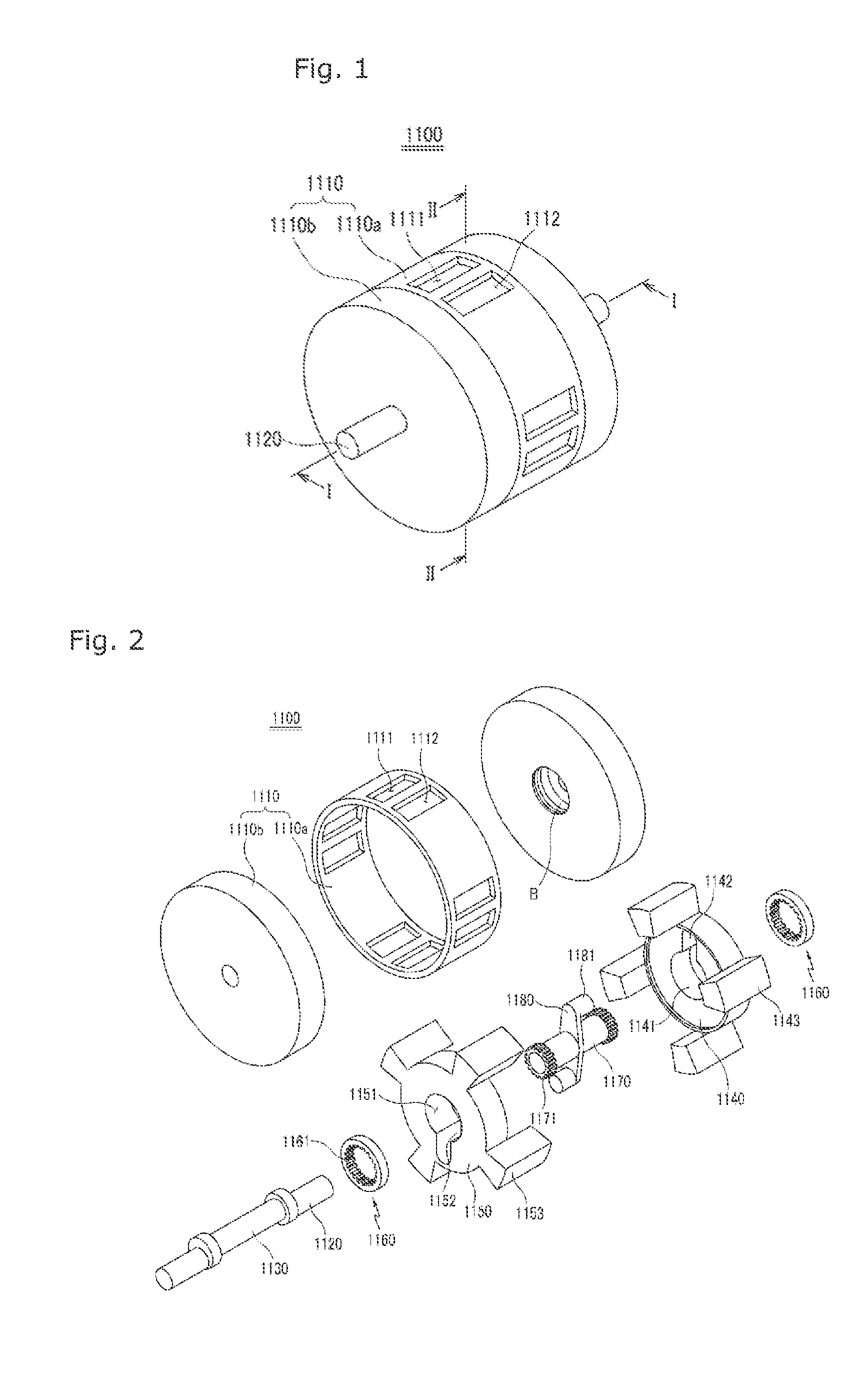

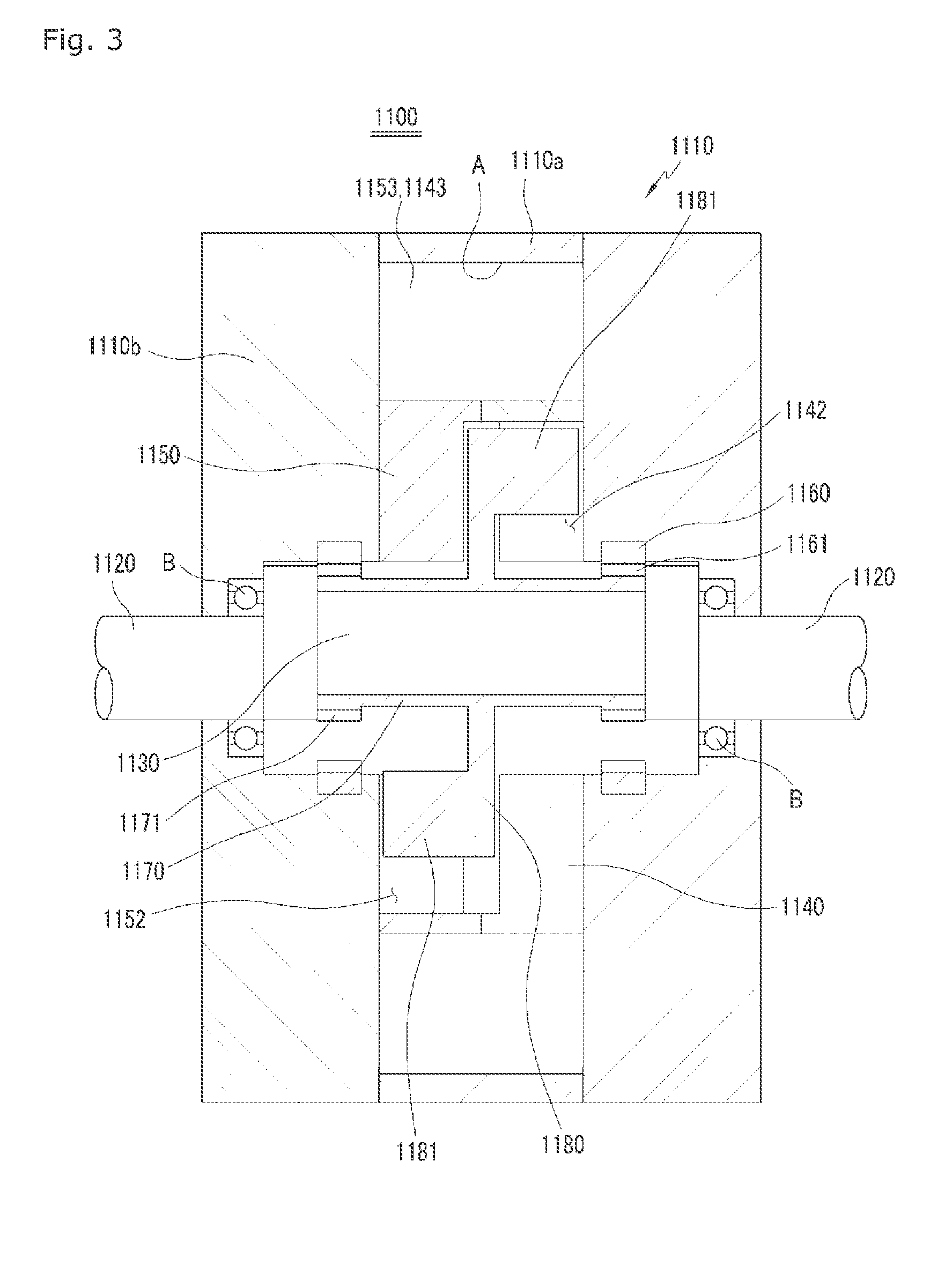

[0104]A rotational clap suction / pressure device 1100 according to a first embodiment of the present invention, in which four blades 1143 and 1153 are disposed on each of first and second rotational pistons 1140 and 1150, will be described.

[0105]Referring to FIGS. 1 to 8, a rotational clap suction / pressure device 1100 according to a first embodiment includes: a cylindrical housing 1110 in which four suction holes 1111 and discharge holes 1112 are defined in a housing cylinder 1110a at a predetermined distance, and a housing side plate 1110b is disposed on each of both sides of the housing cylinder 1110a; a crankshaft 1120 configured to operate a central portion of the housing side plate 1110b, the crankshaft 1120 being rotatably supported by the cylindrical housing 1110; a crankpin 1130 that is eccentric to the crankshaft 1120 to extend from a central portion of the crankshaft 1120; a first rotational piston 1140 rotatably disposed within the cylindrical housing 1110, the first rotat...

second embodiment

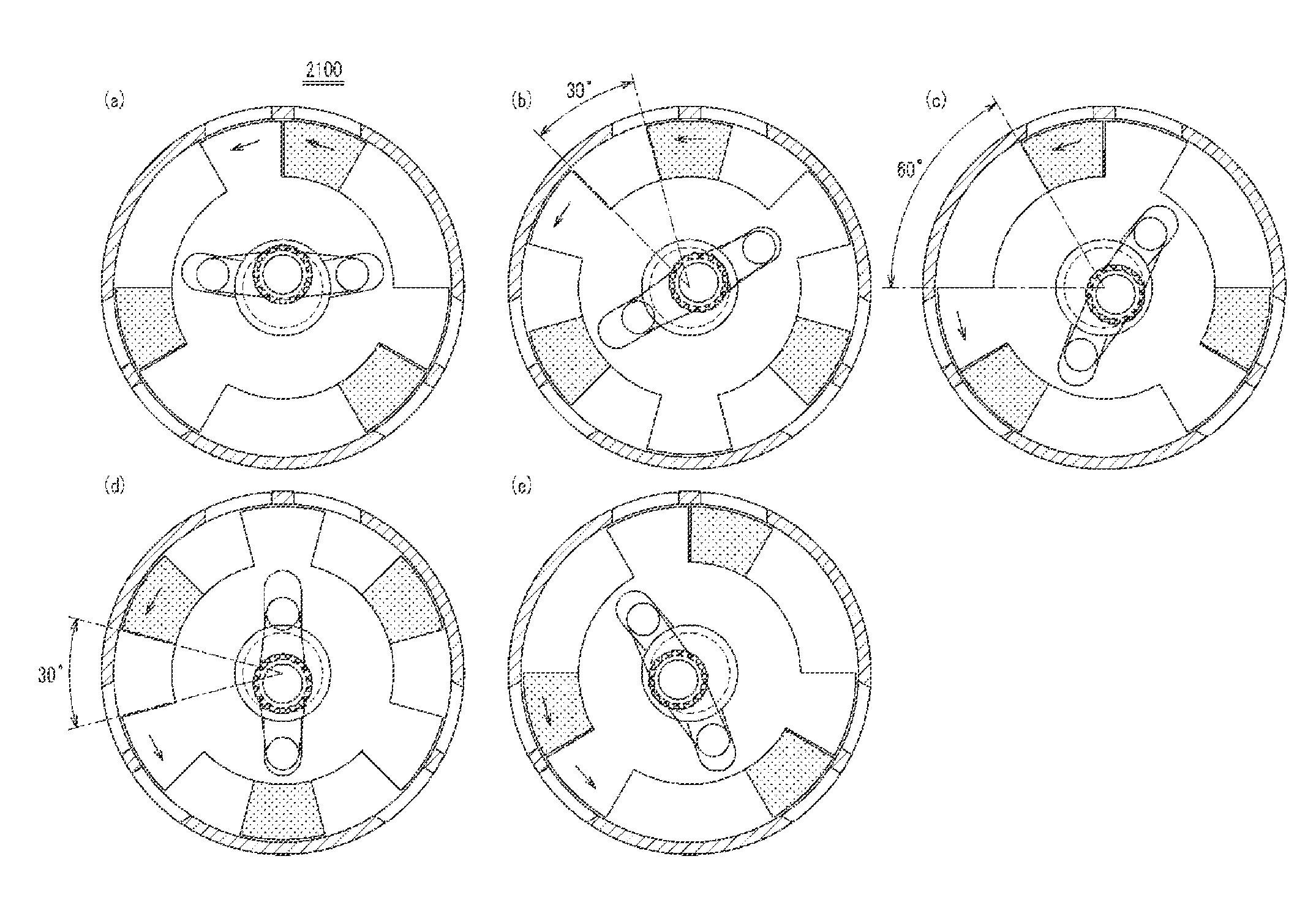

[0117]A rotational clap suction / pressure device 2100 according to a second embodiment of the present invention will be described.

[0118]A rotational clap suction / pressure device 2100 according to the second embodiment of the present invention, in which three blades 1143 and 1153 are disposed on each of first and second rotational pistons 1140 and 1150, will be described. Here, since the rotational clap suction / pressure device 2100 according to the second embodiment of the present invention has the same constitution as the above-described rotational clap suction / pressure device 1100 according to the first embodiment of the present invention except for the number of blades, for convenience of description, the same component is denoted by the same reference numeral.

[0119]Referring to FIGS. 10A to 10E, when the number of each of blades 1143 and 1153 is three, a fixed internal gear 1161 and a planetary external gear 1171 is set to a gear ratio of about 3:2.

[0120]When a crankshaft 1120 is ...

third embodiment

[0122]A rotational clap suction / pressure device 3100 according to a third embodiment of the present invention, in which two blades 1143 and 1153 are disposed on each of first and second rotational pistons 1140 and 1150, will be described. Here, since the rotational clap suction / pressure device 3100 according to the third embodiment of the present invention has the same constitution as the above-described rotational clap suction / pressure device 1100 according to the first embodiment of the present invention except for the number of blades, for convenience of description, the same component is denoted by the same reference numeral.

[0123]Referring to FIGS. 11A to 11E, when the number of each of blades 1143 and 1153 is two, a fixed internal gear 1161 and a planetary external gear 1171 is set to a gear ratio of about 3:2.

[0124]When a crankshaft 1120 is non-uniformly rotated in a clockwise direction by a motor (not shown) that is a power source, a rotation pin 1181 of a connecting rod 118...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com