Measuring point accurate positioning method of generated involute tooth profile measuring apparatus

A technology of involute teeth and measuring points, which is applied in the direction of measuring devices, machine gear/transmission mechanism testing, instruments, etc., can solve the problems of low precision and achieve the effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of this description will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0014] Taking the adjustment of the measuring point position of the double-disk involute measuring instrument as an example, it is explained that the precise positioning of the measuring point position is made by using the tooth profile angle comparison method and the measuring point deviation test value compensation method. Proceed as follows:

[0015] (1) tooth profile angle comparison method to adjust the position of the measuring point

[0016] Take the measurement of m=4, z=30, α=20°involute cylindrical gear tooth profile deviation as an example.

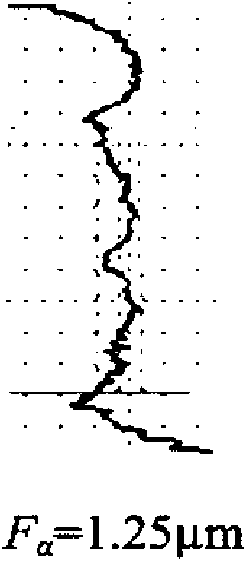

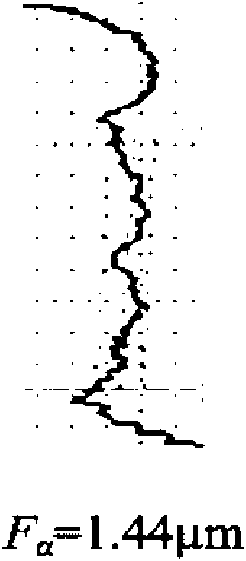

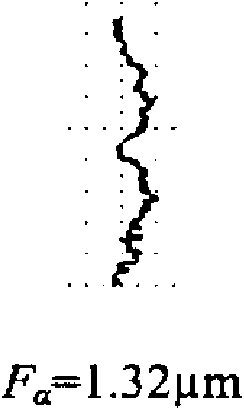

[0017] Firstly, through microscope observation, adjust the measuring point to be lower than the plane of the guide ruler of the instrument, and then measure the deviation of the above-mentioned gear tooth profile. In the measurement curve, take the tooth profi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com