Single-drive multi-gear linkage insulator cleaning device

A gear linkage and cleaning device technology, which is applied to cleaning methods and appliances, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems such as dead angles, increased motors, leakage, etc., to prolong service life and reduce complexity degree, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

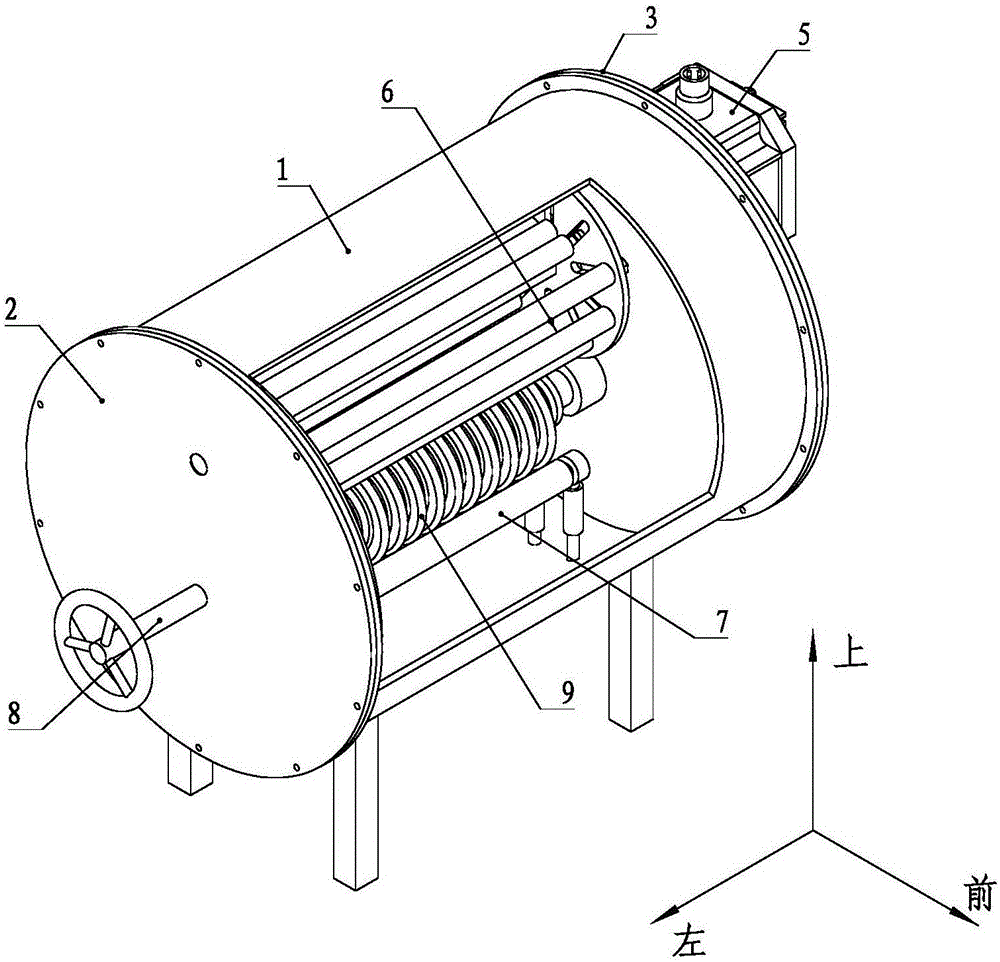

[0043] For the convenience of description, the coordinate system is defined as figure 1 shown.

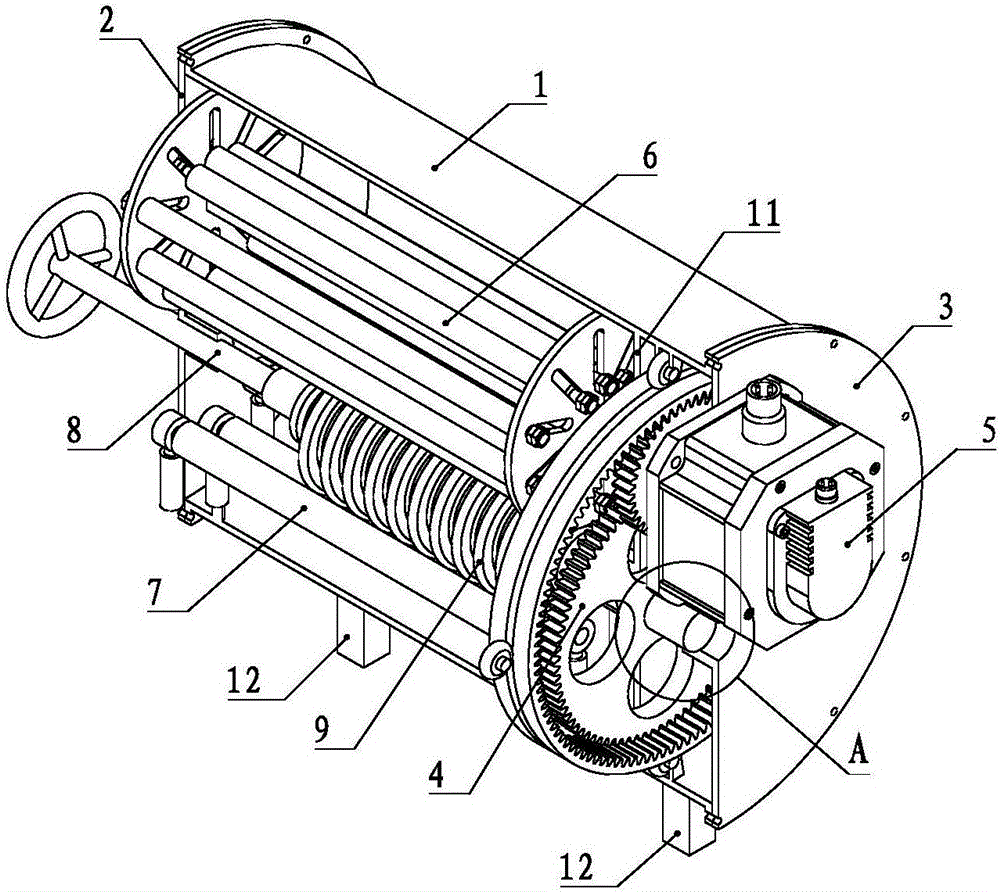

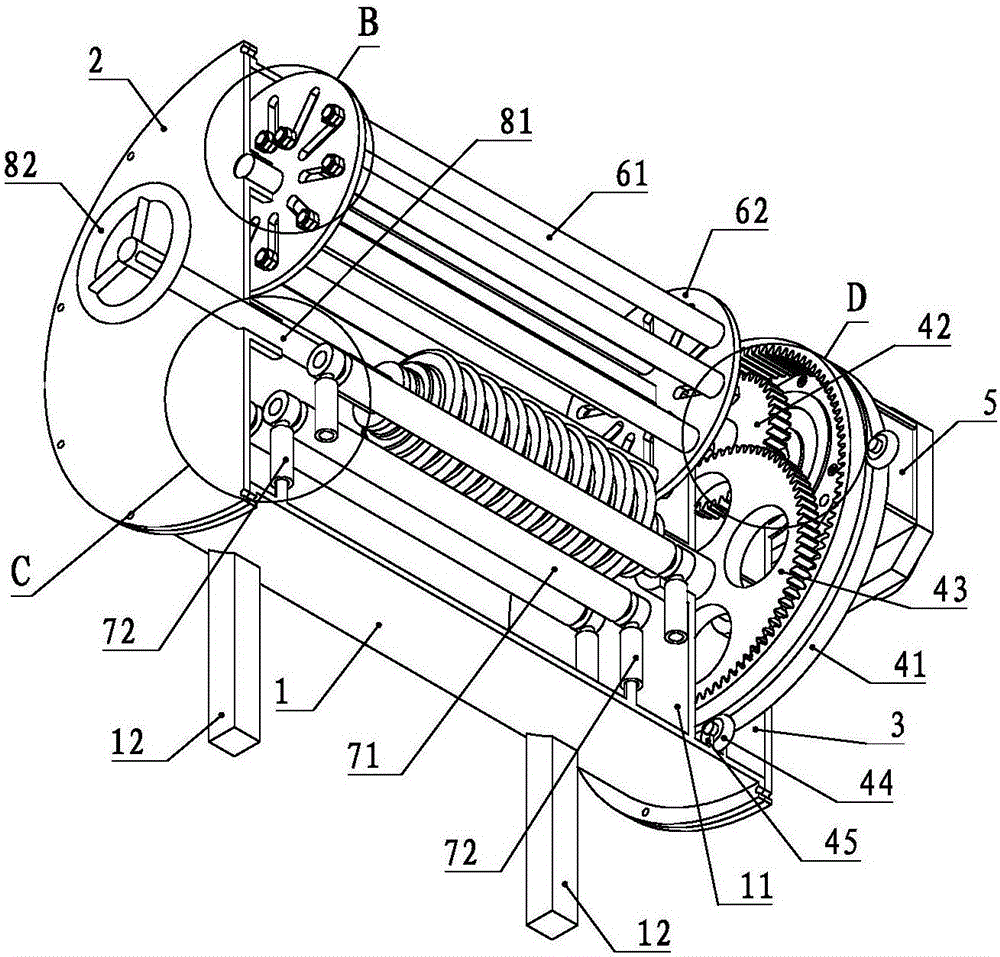

[0044] like figure 1 As shown, a single-drive multi-gear linkage type insulator 9 cleaning device includes a cylindrical cylinder 1, a left end cover 2 is provided on the left side of the cylinder 1, and a right end cover is provided on the right side of the cylinder 1 3. The front side of the barrel 1 is provided with a square notch for picking and placing the insulator 9 . like figure 2 , image 3 and Figure 8 As shown, the interior of the cylinder 1 is provided with a partition 11, the cylinder 1, the partition 11 and the left end cover 2 jointly form a cleaning chamber, and the cylinder 1, the partition 11 and the right end cover 3 jointly form a A transmission chamber is provided, and a transmission mechanism 4 is arranged in the transmission chamber.

[0045] like image 3 and Figure 7As shown, the transmission mechanism 4 includes a large ring gear 41 coaxially ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com