Cutting edge for package container and package container having the same

A technology for packaging containers and cutting blades, applied in the field of cutting blades, can solve the problems of feeling (insufficient sense, problem of cutting performance, problem of durability feeling, etc.), achieve the effect of reducing load, reducing necessity, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

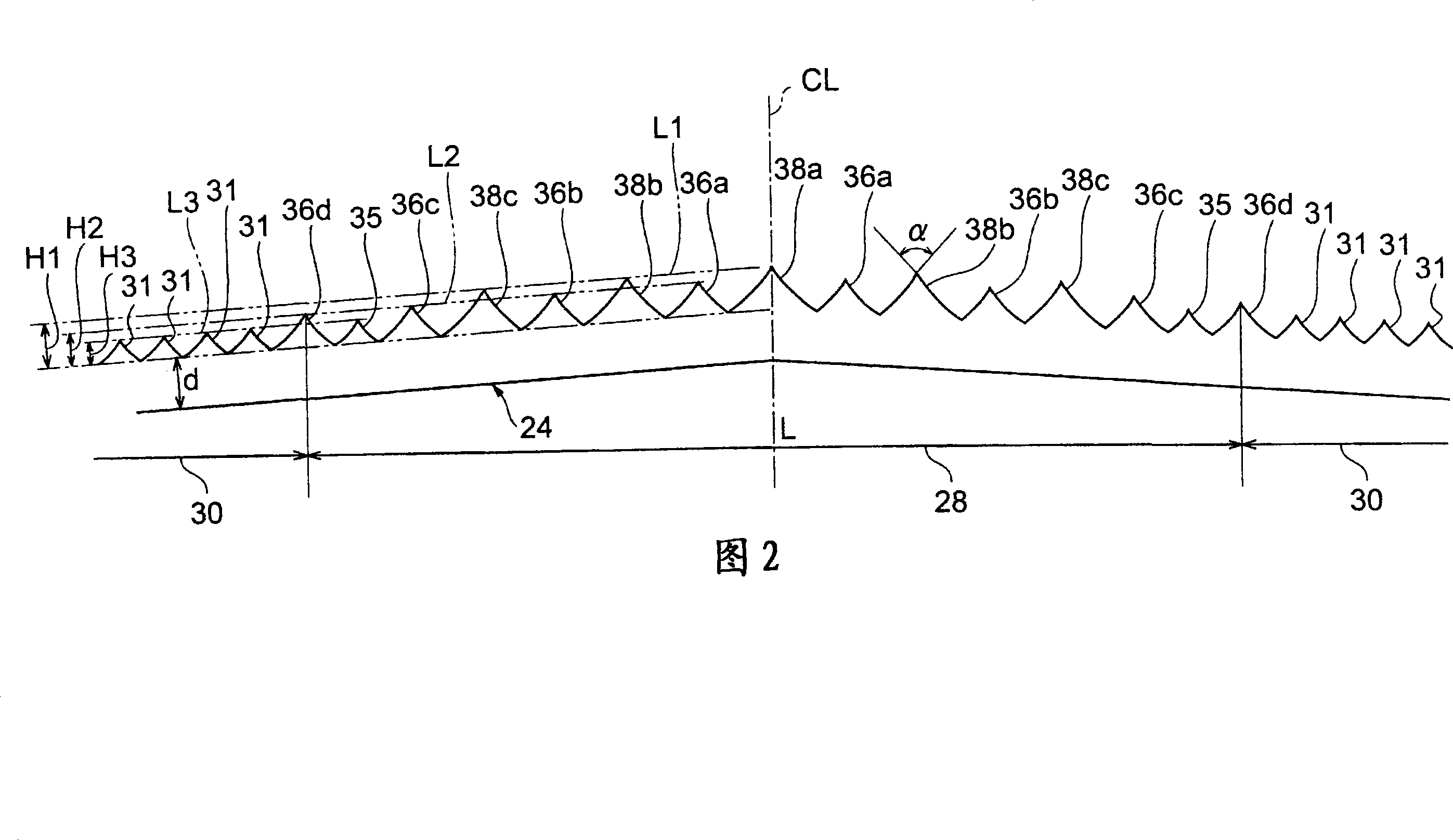

no. 1 approach

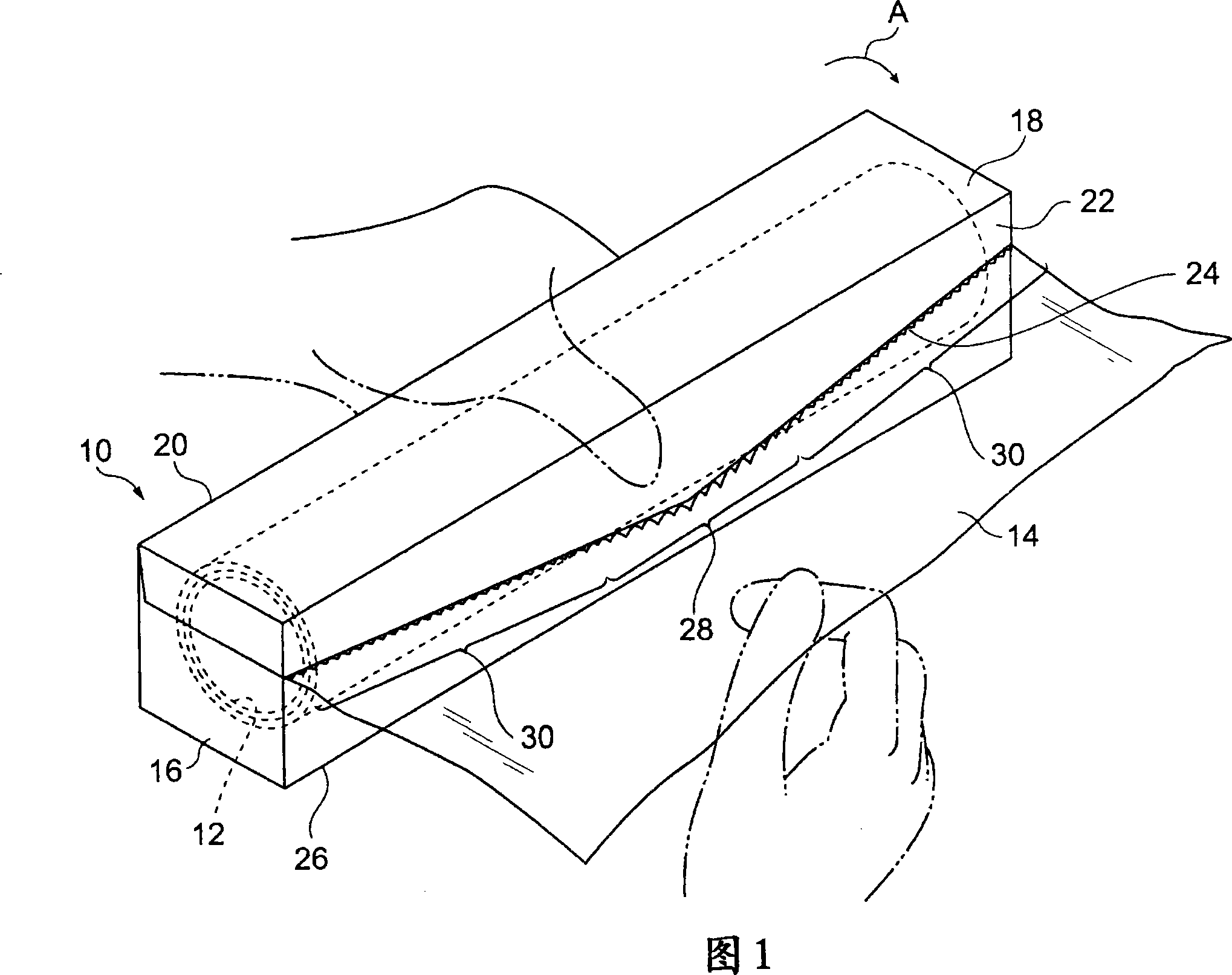

[0071] Fig. 1 is a perspective view showing the form of a packaging container 10 to which the present invention is applied. The packaging container 10 is made of a piece of thick paper, preferably clay coated newsback board. As shown in FIG. 1 , the packaging container 10 includes: a container main body 16 for accommodating a wrapping film 14 wound on a cylindrical paper tube 12 in a roll shape, and a cover body 18 integrally provided with the container main body 16 . When the lid is closed, the overall shape of the packaging container 10 is a substantially rectangular parallelepiped. In addition, in the present embodiment, the stretch film 14 is made of polyvinylidene chloride.

[0072] The upper portion of the container body 16 is opened as an opening for pulling out the wrap film 14 . Additionally, the lid 18 extends continuously from the top edge 20 of the rear wall of the container body 16 . Therefore, the lid body 18 can rotate relative to the container body 16 and c...

no. 2 approach

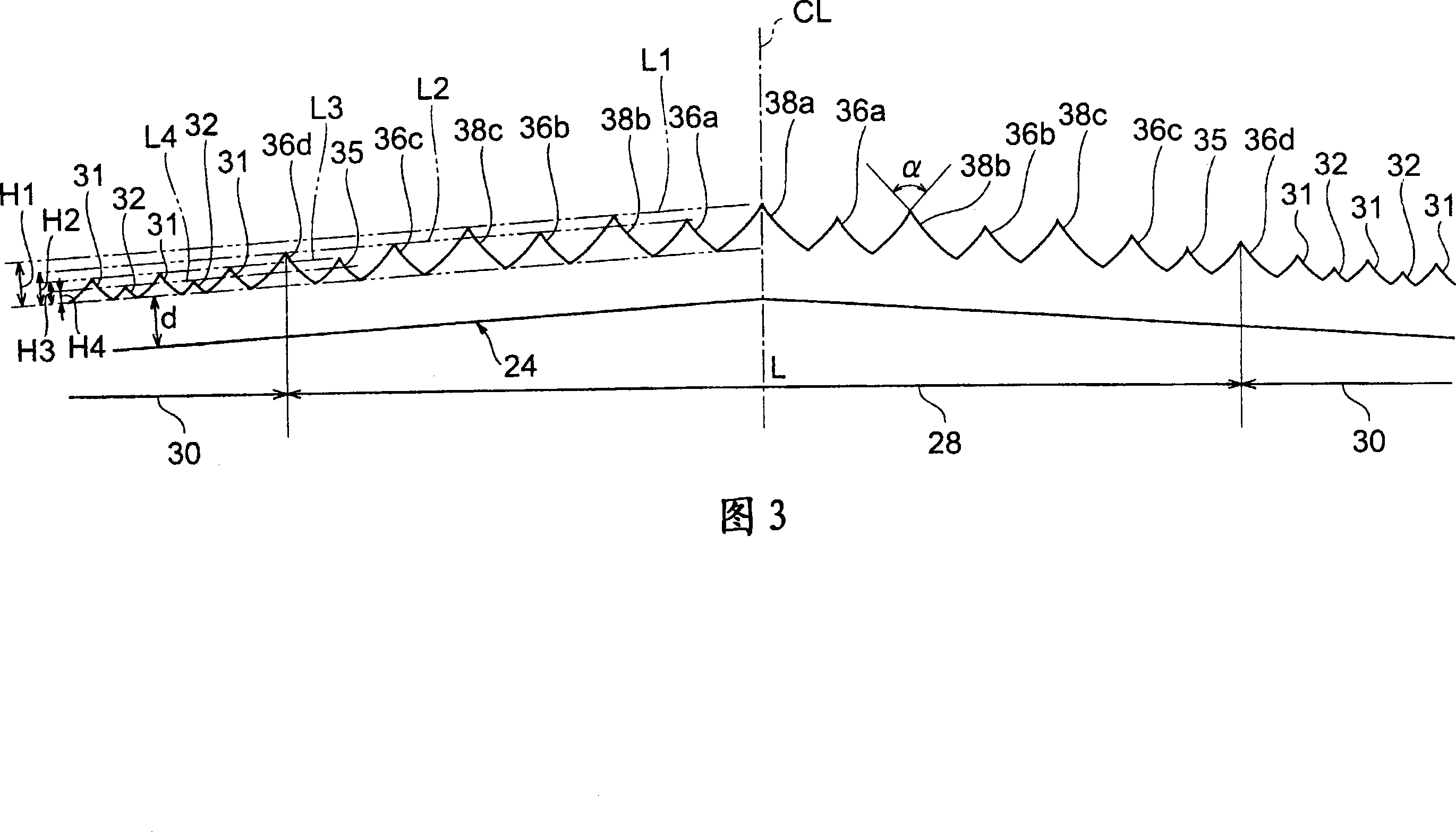

[0095] Fig. 3 is an enlarged view of a central portion of a cutting blade made of resin in a second embodiment of the present invention. The cutting blade 24 in the second embodiment has the same tooth structure in the central region 28 as the central region 28 of the cutting blade 24 in the first embodiment. However, the cutting blade 24 in the second embodiment is different from the cutting blade 24 in the first embodiment in that two types of side teeth having different sizes are provided in the side region 30 .

[0096] 4 is a partially enlarged view of one side region of a cutting blade made of resin in a second embodiment of the present invention. The cutting edge 24 of FIG. 4 includes: a plurality of side teeth (hereinafter referred to as "side first teeth") 31 having the same size as the small teeth 35 of the side region 30, and sandwiched by the first side teeth 31, Side teeth (hereinafter referred to as “side second teeth”) 32 smaller than the side first teeth 31 . ...

no. 3 approach

[0110]5 is a partially enlarged view of one side region of a cutting blade made of resin in a third embodiment of the present invention. Although not shown, the cutting blade 24 in FIG. 5 has the same tooth structure in the central region 28 as the central region 28 of the cutting blade 24 in the first and second embodiments. But the cutting edge 24 of Fig. 5 is equipped with in the side area 30: side teeth (hereinafter referred to as "side 3rd teeth") 33 smaller than the small teeth 35, and sandwiched by the side 3rd teeth 33, smaller than the side teeth 35. A plurality of side teeth (hereinafter referred to as "side fourth teeth") 34 having larger teeth 35 and smaller than the middle teeth 36 differ from the cutting blades 24 in the first and second embodiments. In the side area 30, the third side teeth 33 are arranged adjacent to the middle blade 36d belonging to the central area 28, and the third side teeth 33 and the fourth teeth 34 are located in the longitudinal directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com