Engine position management system and management method

A management system, engine technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve problems such as traffic accidents, car breakdowns, damaged engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

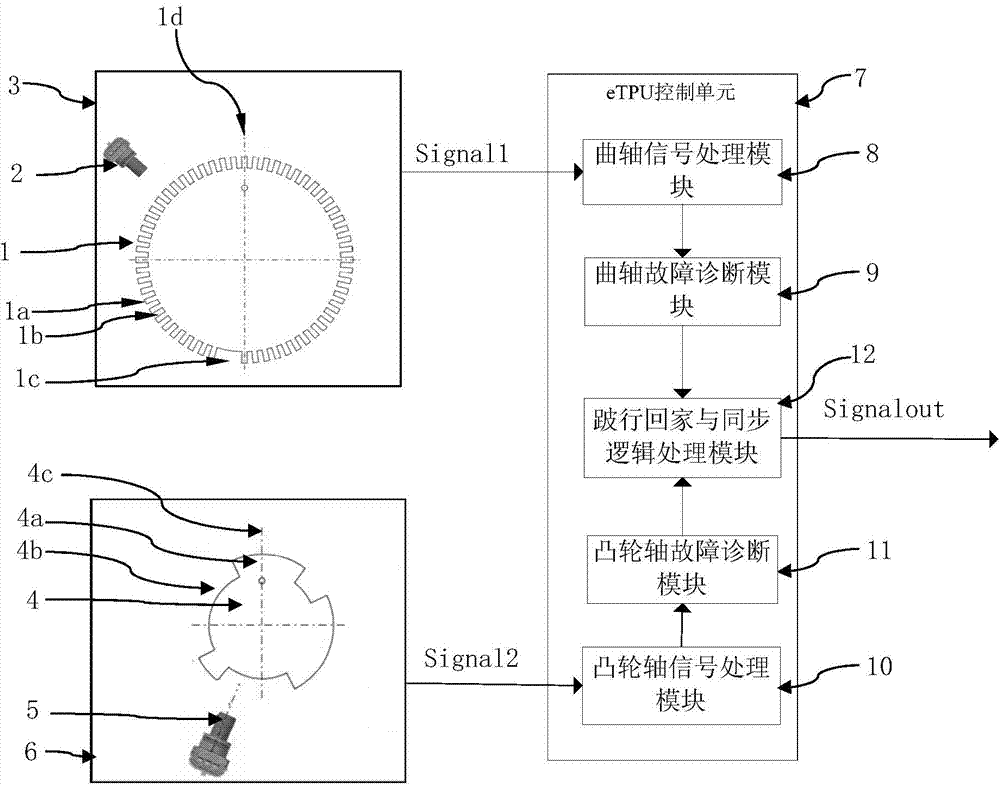

[0063] Such as figure 1 As shown, it is a schematic structural diagram of the engine position management system of the embodiment of the present invention; the engine position management system of the embodiment of the present invention includes:

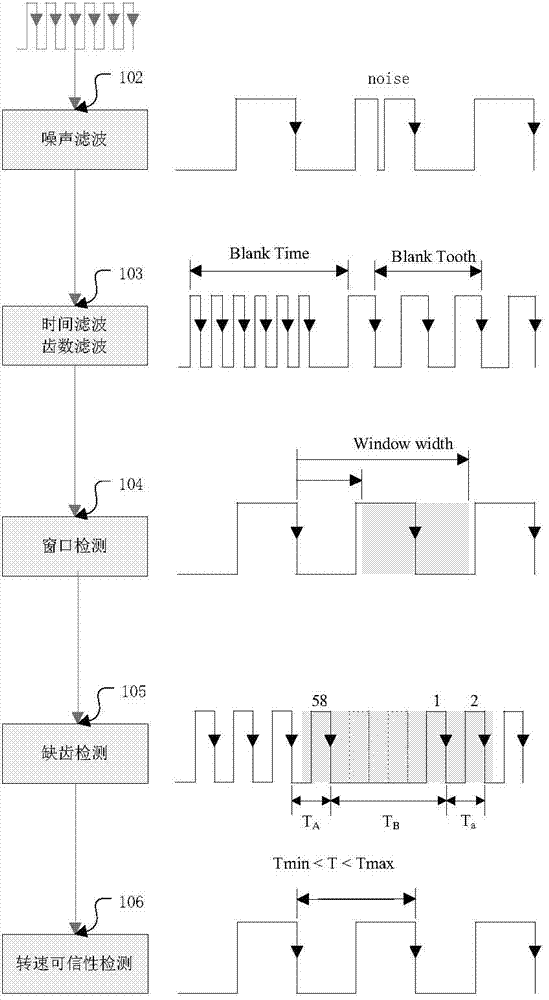

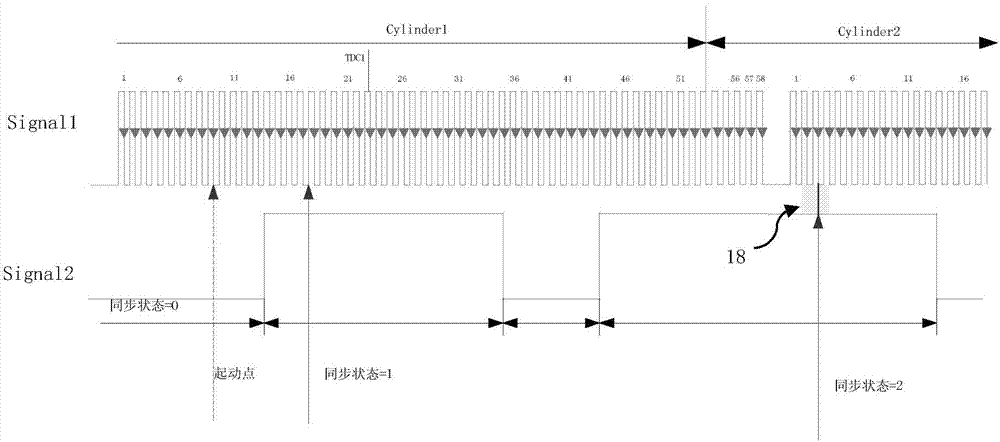

[0064] The crankshaft signal plate 1 is arranged on the crankshaft of the engine and rotates with the crankshaft. The outer circumference of the crankshaft signal plate 1 is formed with a plurality of first protruding teeth 1a, and between two adjacent first protruding teeth 1a A first tooth gap is formed between them, and the first tooth gap includes a first large tooth gap 1c and a plurality of first small tooth gaps 1b, the center angles of each of the first convex teeth 1a are the same, and each of the first small tooth gaps The central angles of the tooth gaps 1b are the same as the central angles of the first protruding teeth 1a, and the central angles of the first large tooth gaps 1c are 5 times the central angle of one of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com