Gear with large tooth lead modification quantity and processing method thereof

A technology of modification amount and tooth direction, which is applied in the direction of belt/chain/gear, components with teeth, portable lifting device, etc. It can solve the problem of increased grinding amount of tooth surface, insufficient tooth surface layer depth of grinding boss, Reduce gear strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

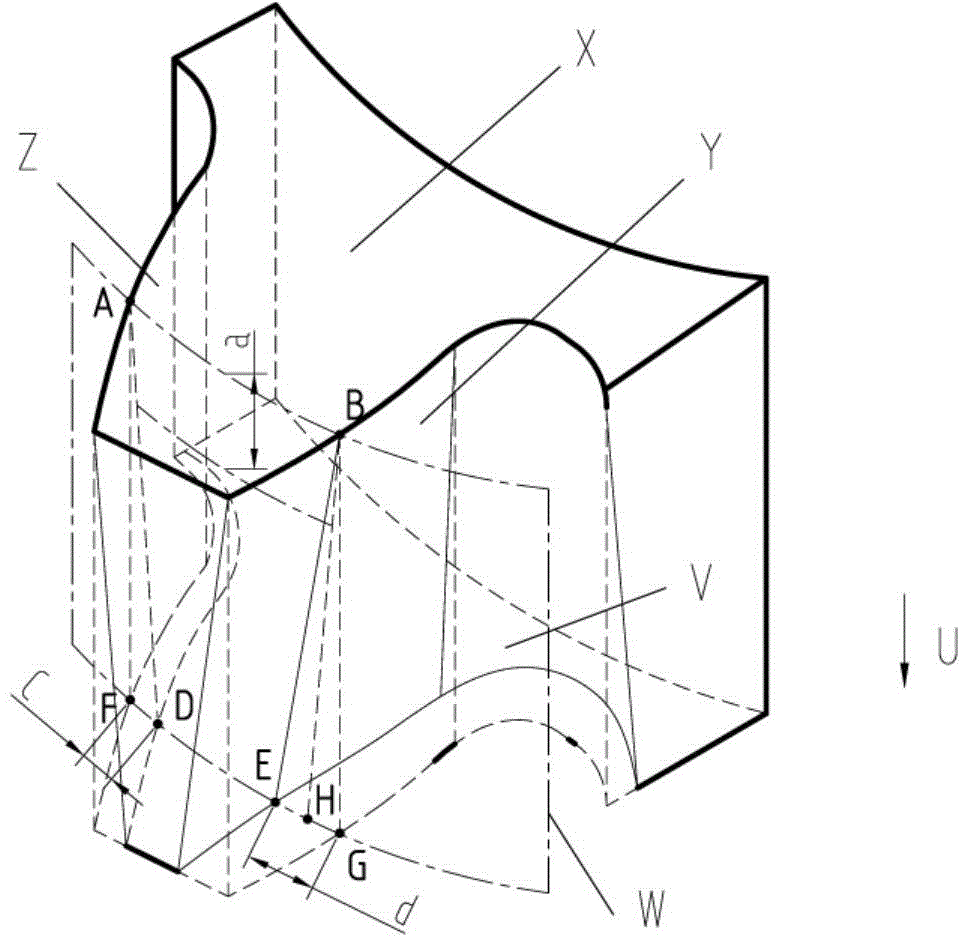

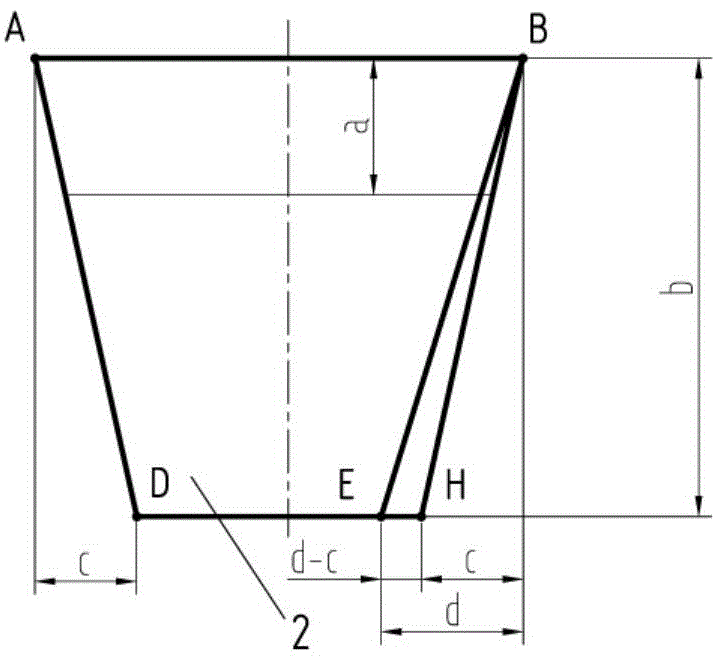

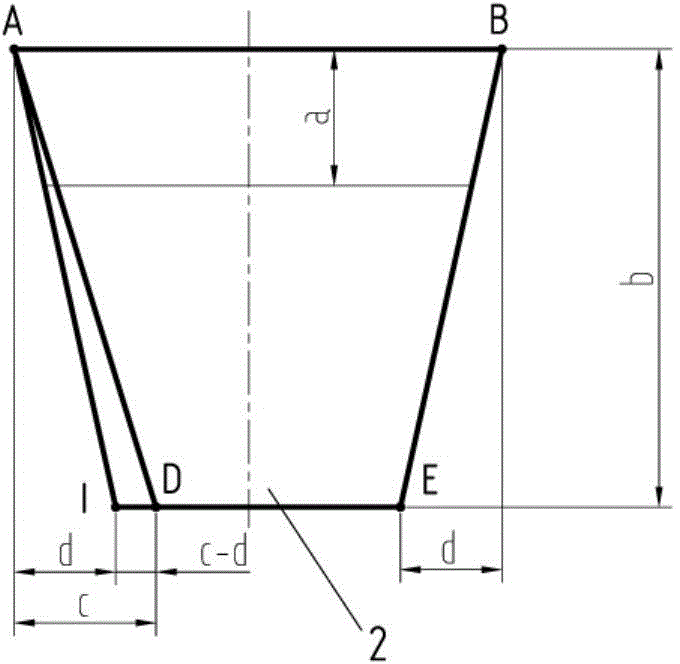

[0049] like figure 1 , 2 , 3, 4, and 5, a gear with a large tooth direction modification amount of the present invention has a tooth number of z, a modulus of m, a tooth width of b, and a pressure angle of α. The large tooth direction modification amount gear 2. The displacement coefficient of the upper end face tooth profile is x, the common normal line of the upper end face tooth profile of the large tooth direction modification gear 2 is W, and the public normal line of the upper end face tooth profile of the large tooth direction modification amount gear 2 W is determined according to the following formulas I and II:

[0050] W=mcosα·[π(k-0.5)+z·invα]+2xmsinα (I),

[0051]

[0052] In formula II, the value of k is rounded to an integer;

[0053] The displacement coefficient of the cross-sectional tooth profile at the distance a from the upper end surface of the gear 2 with large tooth direction modification amount is x a , The public normal line of the cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com