Radial forging and gradual-increment forming method for large-tooth-height thread element

A technology of radial forging and incremental forming, which is applied in the direction of manufacturing tools, engine components, forging/pressing/hammer devices, etc., and can solve the problems of forging screw tooth shape misalignment, increased hammer head wear, and large radial deformation. , to achieve the effect of increasing surface strength and hardness, not easy to forge defects, and small forming force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for radially forging incrementally forming large-tooth-height threaded parts, comprising the following steps:

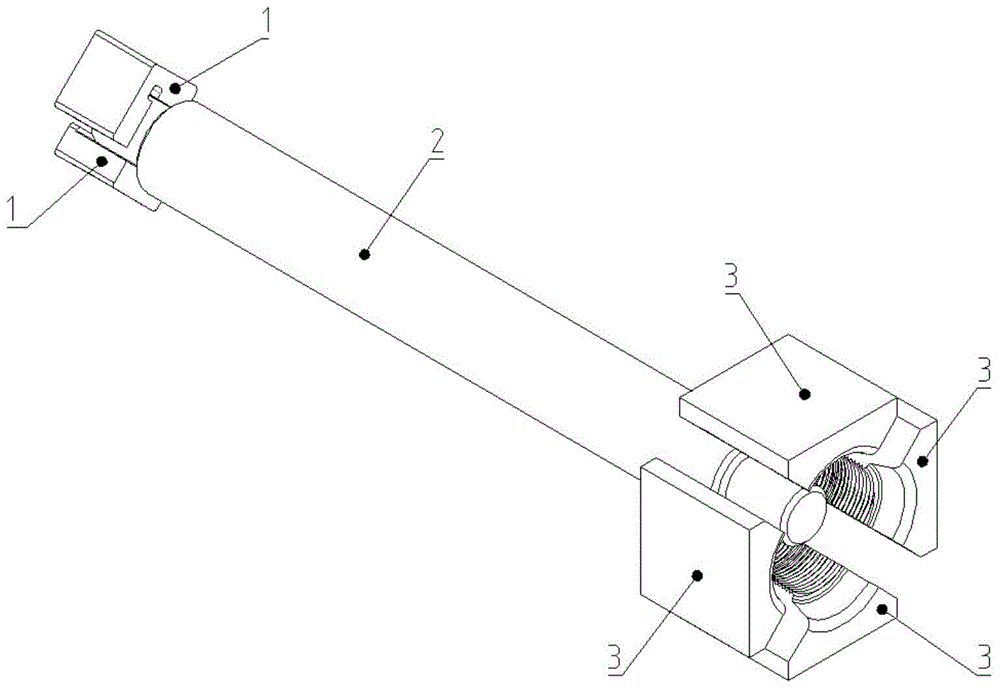

[0035] Step 1, clamping workpiece 2, refer to figure 1 , one end of the workpiece 2 is clamped by the first manipulator 1;

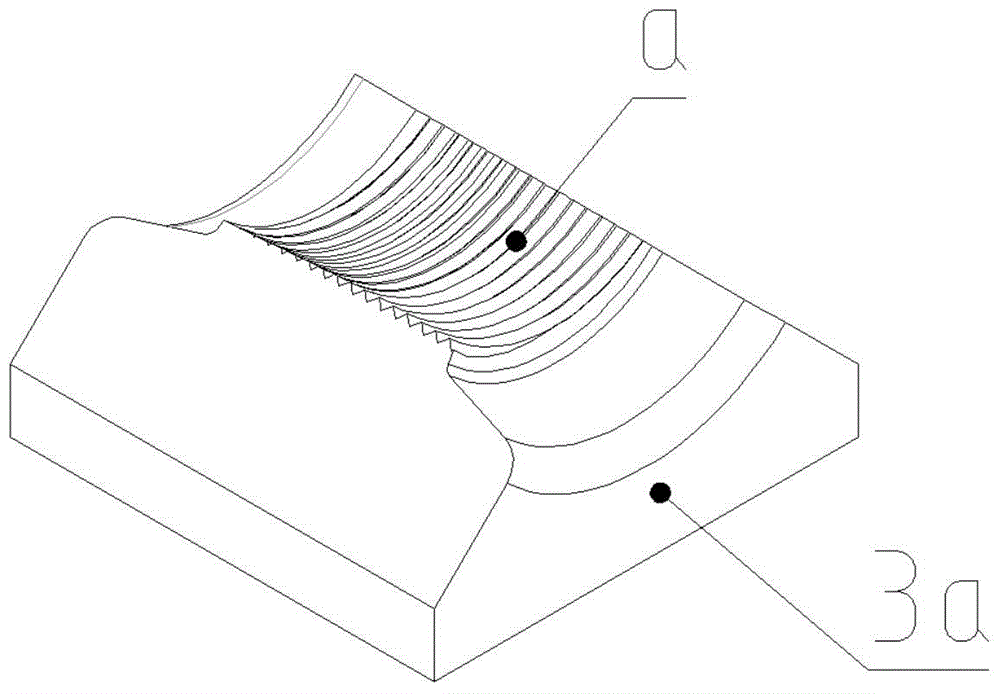

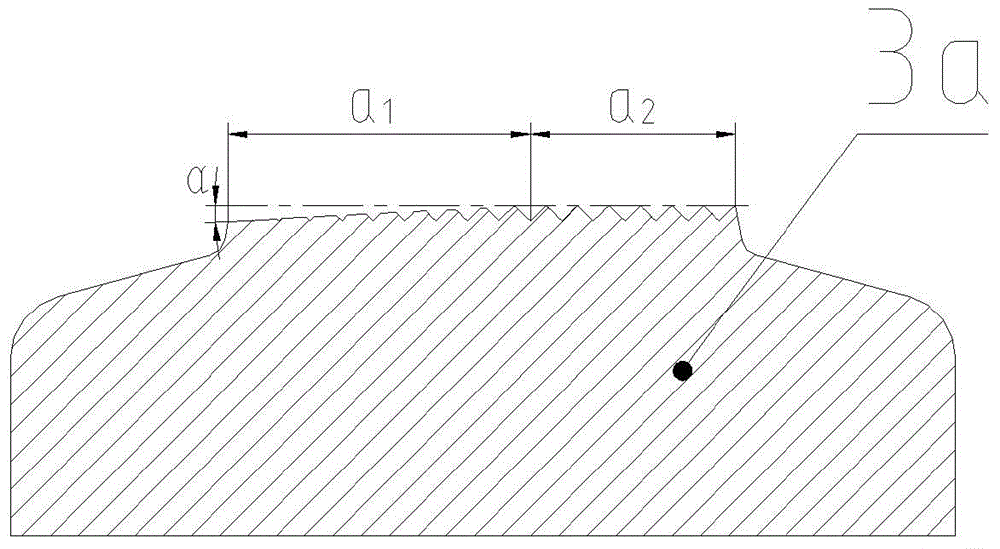

[0036] Step 2, the workpiece 2 is fed axially, the first manipulator 1 clamps the workpiece 2 and feeds it in the direction of the radial forging hammer 3, the hammer 3 has a thread shape segment, and the thread shape segment includes a progressive incremental change thread shape segment and For the thread shape section that does not change the thread, the formed thread section on the workpiece 2 is close to the end of the hammer head 3, and is aligned with the end of the thread shape section on the hammer head 3 that is close to the workpiece 2;

[0037] The hammer head 3 has a thread shape section with gradual incremental changes and a thread shape section with no thread change; The thread shape sections are different; the p...

Embodiment 2

[0050] A method for radially forging incrementally forming large-tooth-height threads, comprising the following steps:

[0051] Step 1, clamping workpiece 2, refer to figure 1 , one end of the workpiece 2 is clamped by the first manipulator 1;

[0052] Step 2, the workpiece 2 is fed axially, the first manipulator 1 clamps the workpiece 2 and feeds it in the direction of the radial forging hammer 3, the hammer 3 has a thread shape segment, and the thread shape segment includes a progressive incremental change thread shape segment and For the thread shape section that does not change the thread, the formed thread section on the workpiece 2 is close to the end of the hammer head 3, and is aligned with the end of the thread shape section on the hammer head 3 that is close to the workpiece 2;

[0053] The hammer head 3 has a thread shape section with gradual incremental changes and a thread shape section with no thread change; The thread shape sections are different; the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com