Robot automatic detection system of intersecting pipeline welded seam

An automatic detection and robot technology, applied in the electromechanical field, can solve the problems of hazards, low detection efficiency, high labor intensity, etc., and achieve the effect of improving detection efficiency, ensuring detection quality, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

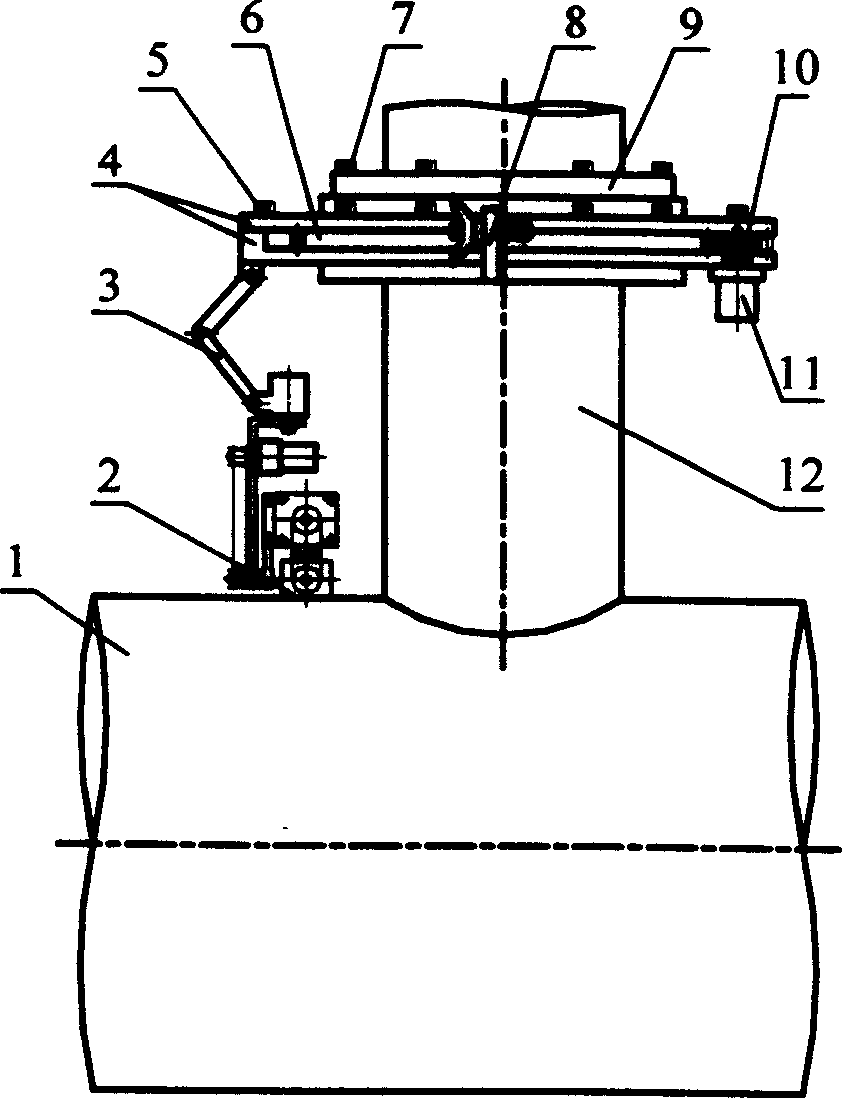

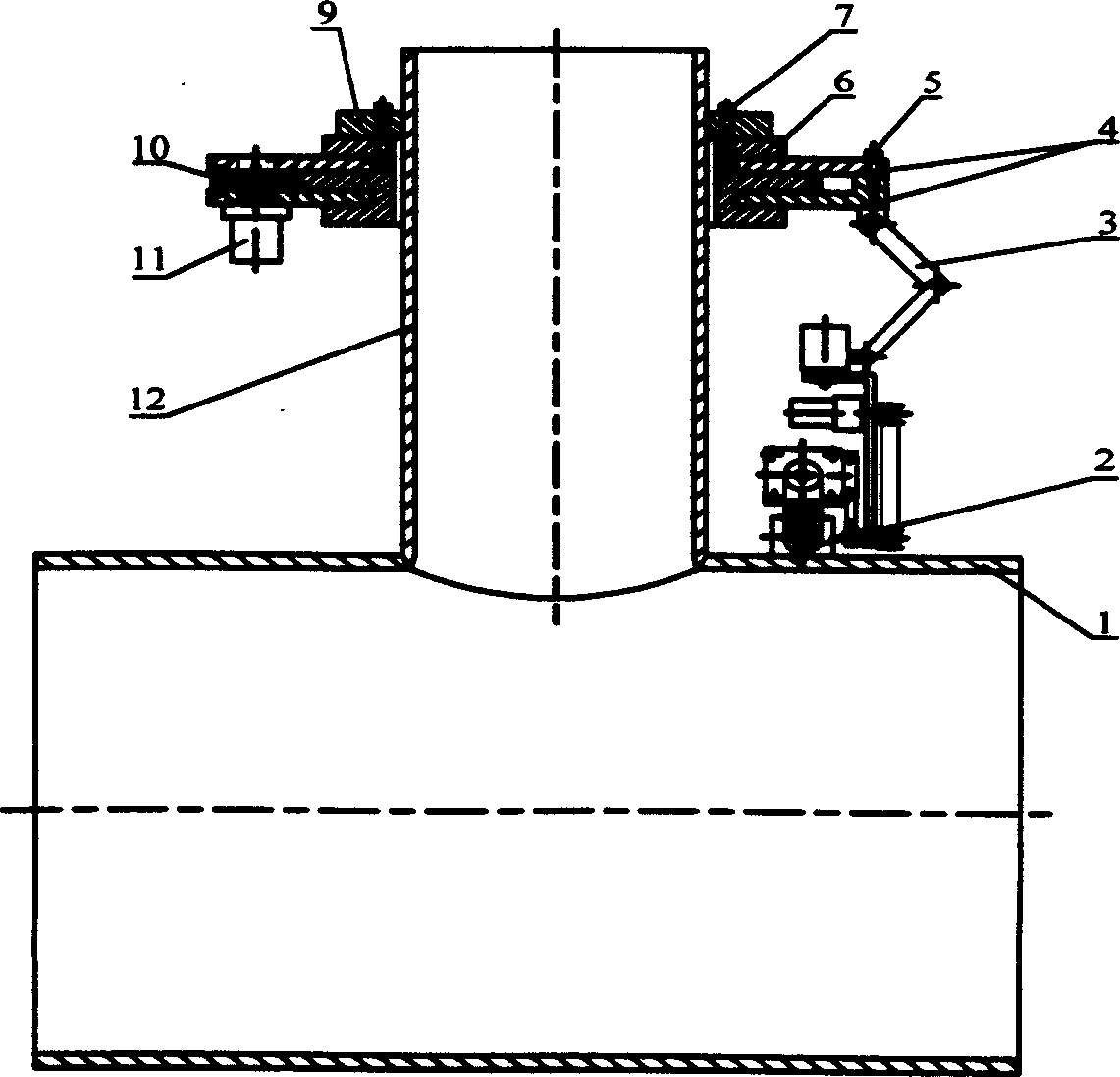

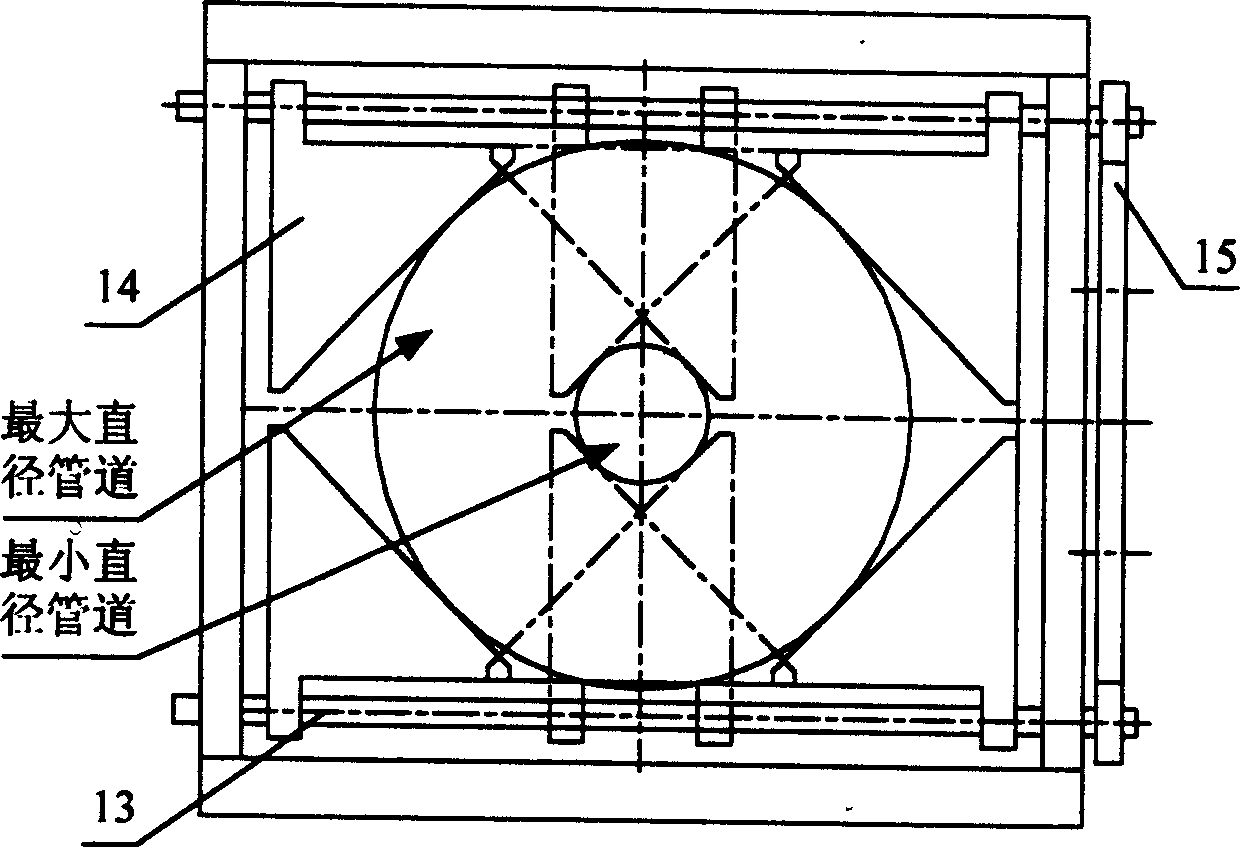

[0015] Such as figure 1 figure 2 As shown, the split circular rotation mechanism is mainly composed of motor 11, planetary pinion 10, upper and lower connecting plates 4, large gear ring 6, quick positioning connecting device 8, connecting bolts 5 and other main components; the robot arm is mainly composed of six free It consists of main components such as robot arm 3 and ultrasonic transducer 2. The six-degree-of-freedom robot arm 3 realizes the position control and attitude control of the ultrasonic transducer.

[0016] The structural connection relationship of each part is as follows: the split fixed support 9 and the large gear ring 6 are connected as a whole by bolts 7, the upper and lower connecting plates 4 are connected as a whole by bolts 5, and the flanges of the motor 11 are fixed on the upper and lower connecting plates 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com