Multi-functional vertical type twisting and untwisting cable forming machine

A multi-functional, cable-forming machine technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems that cannot meet the production requirements of umbilical cord cables, it is difficult to realize the untwisting function of the core, and the standard requirements cannot be met. , to achieve the effect of improving the utilization rate of starting up, stabilizing the line speed and saving investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

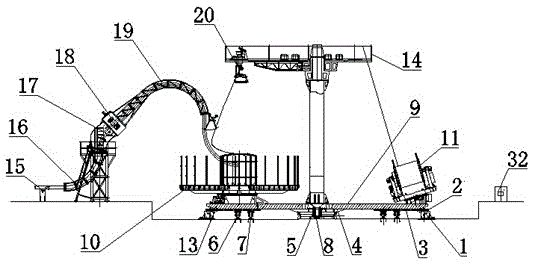

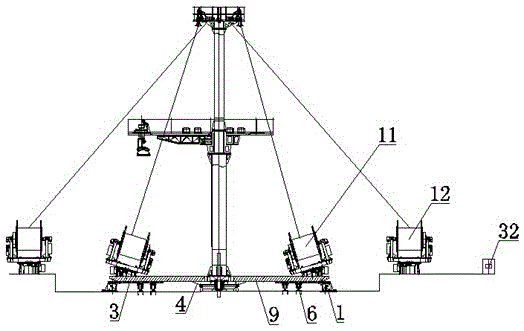

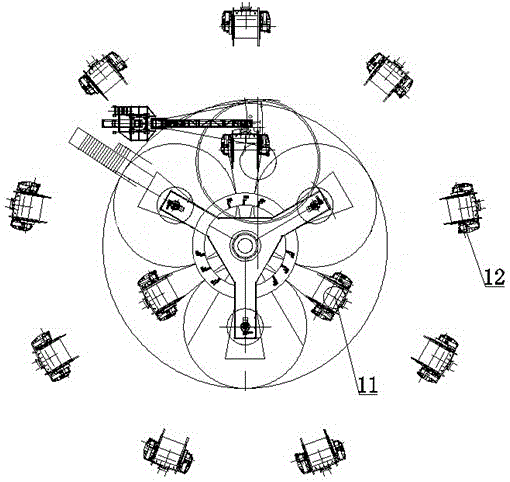

[0022] Such as Figure 1-6 In the shown embodiment, a multifunctional vertical twisting and untwisting cable machine includes a main deceleration variable frequency motor 1 and a twisting body turntable 9, and three large turntables 10 and three fixed small turntables are evenly arranged on the twisting body turntable 9. The turntable 11, the large turntable 10 and the fixed small turntable 11 are distributed across, and the outer circumference of the twisted turntable 9 is fixedly equipped with nine evenly distributed movable small turntables 12, three large turntables 10 and three fixed small turntables 11 realize For the processing of submarine cables, three fixed small turntables 11 and nine movable small turntables 12 realize the processing of multi-core umbilical cables; the lower end of the twisted turntable 9 is provided with an annular large ring gear 3, and the large ring gear 3 is equipped with evenly distributed Supporting wheel device 6, supporting wheel device 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com