Lock washer manufacturing method and lock washer

An anti-loosening washer and a production method technology, applied in the directions of screws, nuts, bolts, etc., can solve the problems of high manufacturing cost and poor anti-loosening effect, and achieve low cost, good anti-loosening effect and high surface hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings.

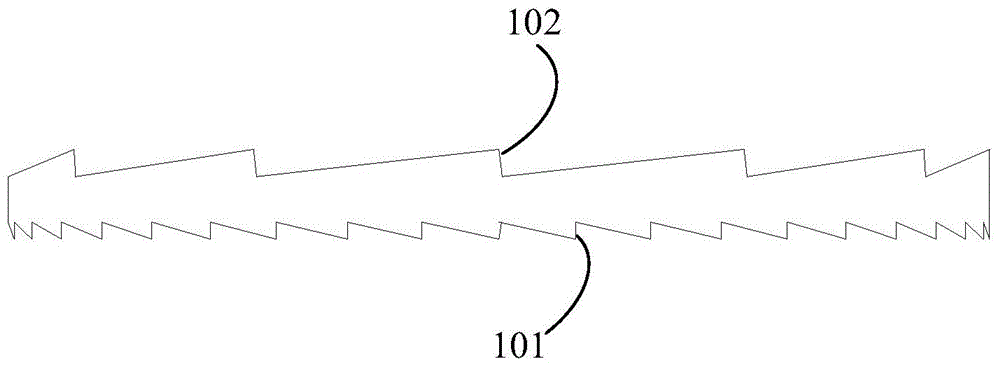

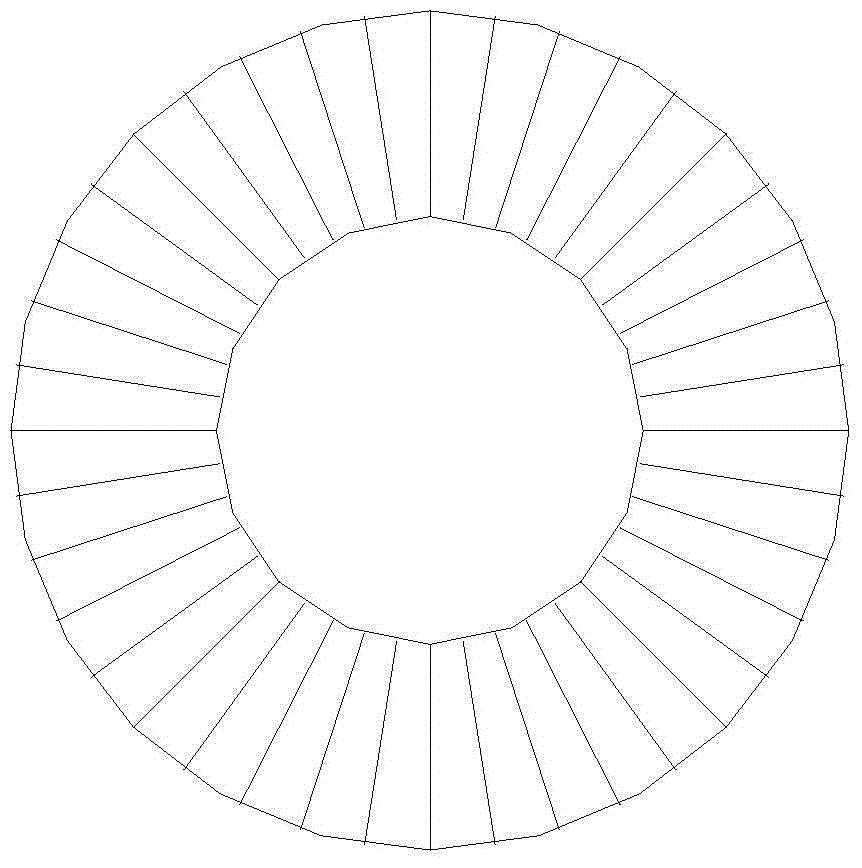

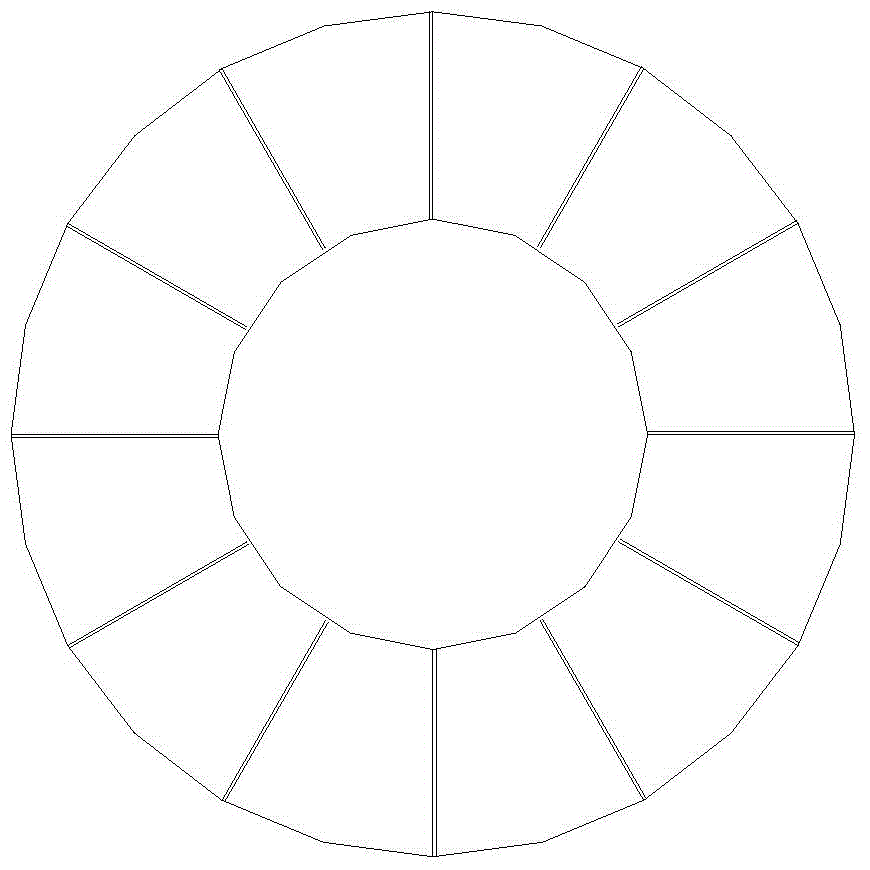

[0024] The idea of the present invention is to solve the problem of anti-loosening effect through the improvement of the washer tooth structure (teeth sharpness, depth, tooth inclination) and surface hardening treatment. For anti-loose washers made of stainless steel, especially austenitic stainless steel, the biggest disadvantage is that the surface hardness cannot be improved by traditional heat treatment processes (such as quenching). For this reason, the gaskets produced by most manufacturers on the market use cold working to form a work-hardened layer on the surface, and the hardness after work-hardening is only 250-400HV 0.05 . The Swedish Nord-Lock company uses its proprietary technology to harden the gasket, but the surface hardness of the gasket after treatment is only greater than 520HV 0.05 . The inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com